In the ceramics industry, inert atmosphere furnaces are primarily used to create a chemically non-reactive environment during high-temperature processing. This controlled atmosphere is essential for preventing unwanted chemical reactions, chiefly oxidation, which would otherwise compromise the structural integrity and performance of advanced ceramic components. By removing oxygen, these furnaces enable processes like sintering and brazing that are impossible to perform correctly in a normal air environment.

The core function of an inert atmosphere furnace in ceramics is to act as a protective shield. This shield prevents oxygen and other contaminants from reacting with the material at high temperatures, ensuring the final product achieves its intended chemical composition and physical properties without defects.

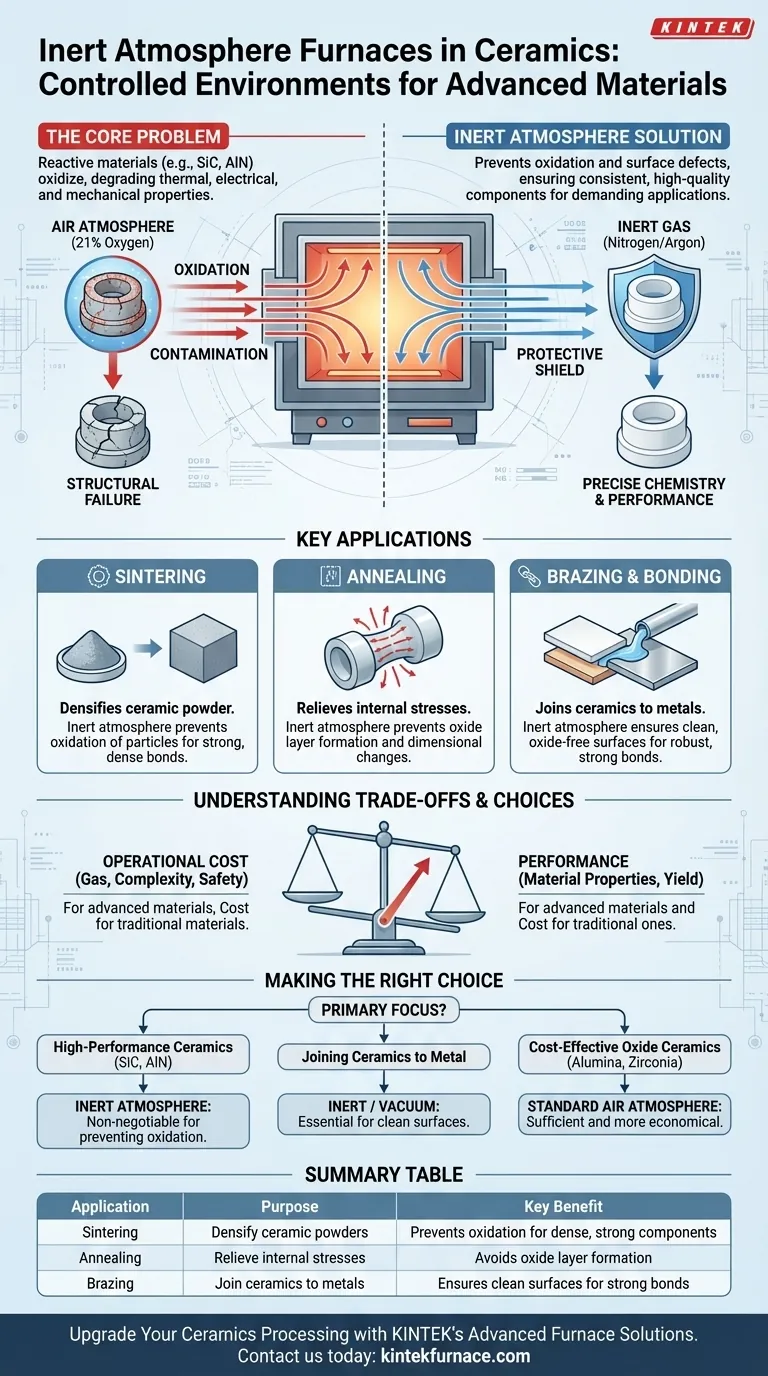

The Core Problem: Why an Inert Atmosphere is Critical

At the high temperatures required for ceramic processing, materials become highly reactive. Exposing them to a standard air atmosphere, which is about 21% oxygen, can lead to catastrophic failures in the final product.

Preventing Unwanted Oxidation

Many advanced ceramics, particularly non-oxide ceramics like silicon carbide (SiC) or aluminum nitride (AlN), will readily oxidize at firing temperatures.

This oxidation changes the material's chemical makeup, degrading its desired properties such as thermal conductivity, electrical insulation, or mechanical strength. An inert atmosphere displaces the oxygen, preventing these destructive reactions from ever starting.

Achieving Precise Material Chemistry

The goal of firing technical ceramics is to achieve a very specific final material structure and composition.

An inert atmosphere provides a stable, predictable environment. This control is critical for producing components with consistent and repeatable properties for demanding applications in the electronics, aerospace, and automotive industries.

Eliminating Surface Contamination

Even trace amounts of reactive gases can cause surface defects or discoloration. For applications like ceramic-to-metal seals or electronic substrates, a pristine surface is non-negotiable.

The inert gas, typically nitrogen or argon, purges the furnace chamber of contaminants, ensuring the ceramic surface remains pure throughout the thermal cycle.

Key Applications in Ceramics Manufacturing

The controlled environment of an inert furnace enables several critical manufacturing processes that are fundamental to producing high-performance ceramics.

Sintering

Sintering is the process of densifying a ceramic powder into a solid object using heat, without melting it.

During sintering, an inert atmosphere prevents the oxidation of the powder particles. This ensures that the particles bond together cleanly, resulting in a dense, strong final component with minimal porosity.

Annealing

Annealing involves heating a ceramic component and holding it at a specific temperature before slowly cooling it. This process relieves internal stresses that may have developed during manufacturing.

Performing this in an inert atmosphere prevents the formation of an oxide layer on the component's surface, which could introduce new stresses or alter its dimensions.

Brazing and Bonding

Inert atmosphere furnaces are essential for joining ceramic components to each other or to metals, a process known as brazing.

The process relies on a filler metal melting and flowing between the two surfaces. If any oxides are present on the ceramic or metal, the filler will not bond properly, creating a weak or failed joint. The inert environment guarantees clean, oxide-free surfaces for a robust bond.

Understanding the Trade-offs

While essential for advanced applications, adopting inert atmosphere technology involves clear operational considerations. It is a precise tool used to solve specific problems, not a universal solution for all ceramic firing.

Operational Cost

The primary trade-off is cost. The inert gases themselves, particularly high-purity argon, represent a continuous operational expense. The furnace systems are also more complex, requiring sealed chambers and gas management systems that add to the initial capital investment.

Process Complexity and Safety

Operating an inert atmosphere furnace requires more rigorous procedures than a standard air furnace. Technicians must manage high-pressure gas cylinders, ensure the furnace chamber is leak-proof, and follow strict protocols for purging and venting the system safely.

Not Always Necessary

Many traditional ceramic products, such as pottery, bricks, and some tiles, are oxide-based and designed to be fired in air. For these applications, the expense and complexity of an inert atmosphere furnace provide no benefit and would be an unnecessary complication.

Making the Right Choice for Your Process

The decision to use an inert atmosphere furnace must be driven by the chemical nature of your material and the performance requirements of the final product.

- If your primary focus is high-performance technical ceramics (e.g., AlN, SiC): An inert atmosphere is non-negotiable to prevent oxidation and achieve the required material properties.

- If your primary focus is joining ceramics to metal: An inert or vacuum furnace is essential to create the clean, oxide-free surfaces required for a strong brazed joint.

- If your primary focus is cost-effective production of oxide ceramics (e.g., alumina, zirconia): A standard air-atmosphere furnace is often sufficient, simpler, and more economical unless specific additives are sensitive to oxygen.

- If your primary focus is artistic or traditional pottery: An inert atmosphere is unnecessary, as the chemistry of glazes and clay bodies is formulated for firing in an oxygen-rich environment.

Ultimately, choosing the correct furnace atmosphere is a critical decision that directly determines the quality, performance, and viability of your ceramic component.

Summary Table:

| Application | Purpose | Key Benefit |

|---|---|---|

| Sintering | Densify ceramic powders into solids | Prevents oxidation for dense, strong components |

| Annealing | Relieve internal stresses in ceramics | Avoids oxide layer formation and stress changes |

| Brazing | Join ceramics to metals or other ceramics | Ensures clean, oxide-free surfaces for strong bonds |

Upgrade Your Ceramics Processing with KINTEK's Advanced Furnace Solutions

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're sintering silicon carbide, annealing aluminum nitride, or brazing ceramic-metal joints, our furnaces deliver reliable inert atmospheres to prevent oxidation and contamination, ensuring superior material properties and process consistency.

Contact us today to discuss how our tailored solutions can enhance your ceramics manufacturing—Get in touch now!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality

- What does inert mean in furnace atmospheres? Protect materials from oxidation with inert gases.

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance