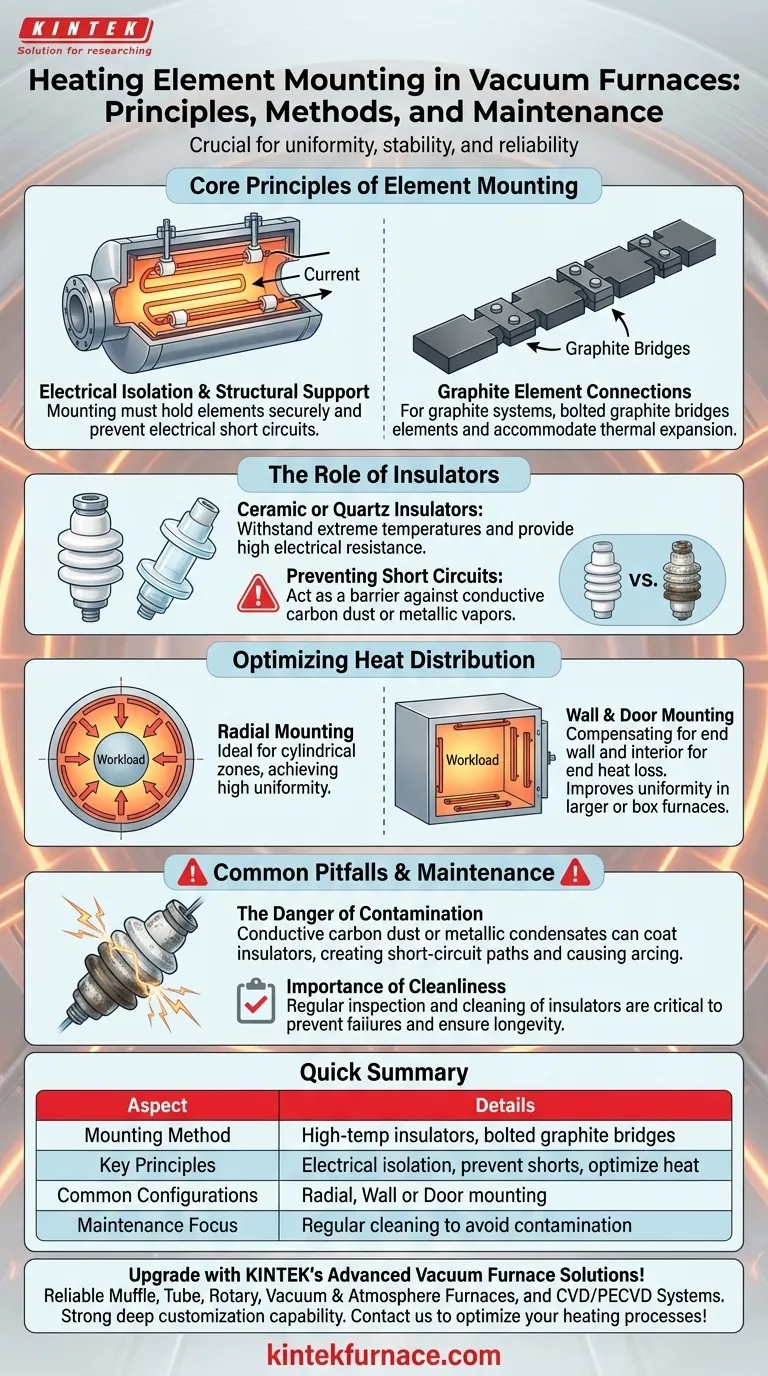

In a vacuum furnace, heating elements are mounted using specialized high-temperature insulators, most commonly made of ceramic or quartz. For graphite-based systems, the individual elements are connected to each other and the power feedthroughs using bolted graphite bridges. This mounting system is designed not just for physical support, but to provide critical electrical isolation and ensure stable, uniform heating in the demanding vacuum environment.

The method used to mount a heating element is a critical design choice that directly impacts the furnace's temperature uniformity, electrical stability, and long-term reliability. The core challenge is maintaining perfect electrical isolation while ensuring consistent heat distribution, especially as contaminants can build up during operation.

The Core Principles of Element Mounting

The mounting strategy for a heating element must solve two fundamental problems simultaneously: holding the element securely in place at extreme temperatures and preventing the electrical current from short-circuiting.

Ensuring Electrical Isolation

The primary function of the mounting hardware is to isolate the electrically charged heating element from the furnace's metallic body and heat shields. While a vacuum is an excellent electrical insulator, the furnace environment is not perfectly clean.

Over time, carbon dust from graphite elements or metallic vapors from the heated workload can settle throughout the furnace. If these conductive materials build up on an insulator, they can create a path for electricity to bypass the element, leading to a short circuit.

The Role of Insulators

To prevent short-circuiting, elements are suspended on specialized insulators. Materials like ceramic or quartz are chosen for their ability to withstand extreme temperatures while maintaining very high electrical resistance.

These insulators act as the critical barrier between the energized element and the grounded furnace structure. Their effectiveness is paramount to the safe and reliable operation of the furnace.

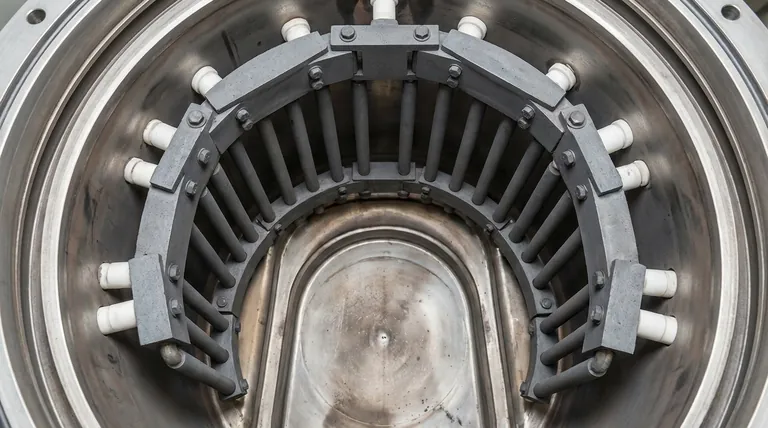

Structural Connection for Graphite Elements

Graphite elements are not a single, continuous piece. They are typically assembled from segments connected using bolted graphite bridges.

Using graphite for both the elements and the connectors ensures that all components expand and contract at the same rate with temperature changes. This material consistency prevents mechanical stress and maintains a reliable electrical connection at temperatures that can exceed 3000°C.

Optimizing Heat Distribution

The physical placement of the heating elements within the hot zone is engineered to deliver the most uniform temperature possible to the workload.

Radial Mounting

In cylindrical hot zones, elements are often mounted radially, forming a circle around the workload. This configuration provides even, 360-degree heating, which is ideal for achieving high temperature uniformity in a contained space.

Wall and Door Mounting

To further improve uniformity, especially in larger or box-shaped furnaces, elements may also be mounted on the rear walls or the interior of the furnace door. This compensates for heat loss that naturally occurs at the ends of the hot zone, ensuring the entire workload reaches the target temperature consistently.

Common Pitfalls to Avoid

The reliability of a vacuum furnace is directly tied to the condition of its heating element mounting system. Neglecting this area is a common source of failure.

The Danger of Contamination

The single greatest threat to heating element insulators is contamination. The fine carbon dust or metallic condensates generated during heating cycles are conductive.

When these deposits coat an insulator, they effectively create a short-circuit path. This can cause arcing, which may destroy the insulator, damage the heating element, and potentially trip or destroy the power supply.

The Importance of Cleanliness

Because of this risk, keeping insulators clean is a critical maintenance task. They must be regularly inspected and cleaned to remove any conductive buildup. This simple act of maintenance is fundamental to preventing catastrophic electrical failures and ensuring the furnace's longevity.

Making the Right Choice for Your Goal

The design and maintenance of the element mounting system should align with your operational priorities.

- If your primary focus is maximum temperature uniformity: A design using a combination of radial elements and supplemental wall- or door-mounted elements is the most effective approach.

- If your primary focus is operational reliability: Implement a strict and frequent maintenance schedule focused on inspecting and cleaning all ceramic or quartz insulators to prevent contaminant buildup.

- If your primary focus is high-temperature graphite systems: Ensure all electrical connections between element segments are made with graphite hardware to manage thermal expansion and prevent connection failures.

Ultimately, proper heating element mounting is a foundational aspect of furnace performance, directly governing both its heating capability and its operational lifespan.

Summary Table:

| Aspect | Details |

|---|---|

| Mounting Method | Uses high-temperature insulators (e.g., ceramic, quartz) and bolted graphite bridges for connections |

| Key Principles | Ensures electrical isolation, prevents short circuits, and optimizes heat distribution |

| Common Configurations | Radial mounting for cylindrical zones; wall or door mounting for uniformity |

| Maintenance Focus | Regular cleaning of insulators to avoid contamination from carbon dust or metallic vapors |

Upgrade your lab's capabilities with KINTEK's advanced vacuum furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable high-temperature systems, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs for superior performance and longevity. Contact us today to discuss how we can optimize your heating processes and enhance efficiency!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today