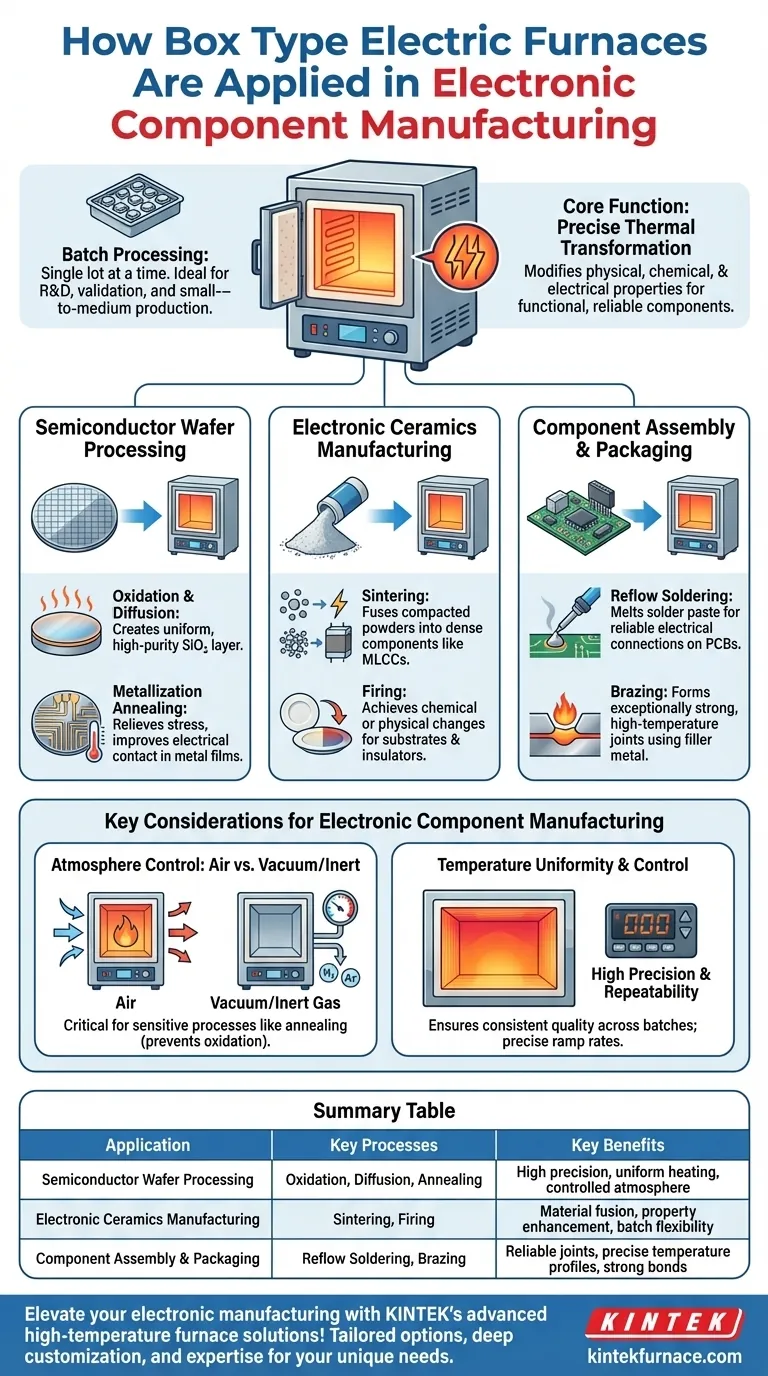

In electronic component manufacturing, box-type electric furnaces are primarily used to execute precise thermal processes. These include the manufacturing of ceramic components like capacitors, heat treatment and annealing of semiconductor wafers, and assembly processes such as reflow soldering and packaging.

The core function of a box furnace in electronics is not simply heating, but a highly controlled thermal transformation. It precisely modifies the physical, chemical, and electrical properties of materials to create functional and reliable components.

The Role of Thermal Processing in Electronics

A box-type electric furnace is fundamentally an insulated chamber that uses electric resistance to achieve high, uniform temperatures. Its value in electronics comes from its ability to execute these thermal cycles with high precision and repeatability.

Why Temperature is a Manufacturing Tool

Nearly every advanced electronic component relies on materials whose properties were set by a specific thermal process.

Applying heat in a controlled manner can alter a material's crystal structure, relieve internal stresses, diffuse chemicals into a substrate, or fuse powdered materials into a solid, dense form.

The Importance of Batch Processing

Box furnaces are a form of batch furnace. This means they process a single lot of components at a time.

This makes them exceptionally well-suited for research and development, process validation, and small-to-medium scale production where flexibility and precision are more critical than sheer volume.

Key Applications in Component Manufacturing

The versatility of box furnaces allows them to be used at multiple stages of the electronics value chain, from raw wafer processing to final assembly.

Semiconductor Wafer Processing

Before a silicon wafer is diced into individual chips, it undergoes numerous thermal steps.

- Oxidation and Diffusion: Furnaces create a uniform, high-purity silicon dioxide (SiO₂) layer on wafers through thermal oxidation. This layer acts as a critical insulator or a mask for subsequent steps.

- Metallization Annealing: After thin layers of metal (like aluminum) are deposited to form circuits, an annealing process is used. This low-temperature heat treatment relieves stress in the metal film, repairs damage, and improves the electrical contact between the metal and the silicon.

Manufacturing of Electronic Ceramics

Many essential passive components are ceramic-based.

- Sintering: This process is used to create components like Multilayer Ceramic Capacitors (MLCCs) and piezoelectric sensors. A furnace heats compacted ceramic powders to just below their melting point, causing the particles to fuse together into a dense, solid component with specific electrical properties.

- Firing: Similar to sintering, this involves heating materials to achieve a chemical or physical change, essential for creating various ceramic substrates and insulators.

Component Assembly and Packaging

Once individual components are made, they must be assembled onto a circuit board.

- Reflow Soldering: In this process, solder paste is used to attach components to a PCB. The entire assembly is heated in a furnace following a precise temperature profile, which melts the solder to create strong and reliable electrical connections.

- Brazing: For components that require exceptionally strong, high-temperature joints, brazing is used. A furnace melts a filler metal to join two parts, creating a bond that is often stronger than the components themselves.

Understanding the Key Considerations

Choosing a furnace is not a one-size-fits-all decision. The specific process dictates the required features, particularly the furnace's atmosphere.

Atmosphere Control: Air vs. Vacuum

The atmosphere inside the furnace is a critical process variable.

- Air Atmosphere: Standard box furnaces operate with air. This is suitable for many processes like firing ceramics or basic heat treatments where oxidation is not a concern.

- Controlled Atmosphere: Many semiconductor processes, such as annealing, are extremely sensitive to oxygen. For these applications, a vacuum furnace or a furnace filled with an inert gas (like nitrogen or argon) is essential to prevent unwanted chemical reactions.

Temperature Uniformity and Control

The quality of an electronic component is directly tied to the furnace's performance. A variance of even a few degrees across a batch of wafers or capacitors can lead to inconsistent performance and device failure.

Therefore, high temperature uniformity throughout the chamber and precise control over heating and cooling rates (ramp rates) are the most critical specifications of a furnace for electronics manufacturing.

Making the Right Choice for Your Goal

The right thermal solution depends entirely on your specific application and scale.

- If your primary focus is material research or process development: A versatile, lab-scale box furnace with precise temperature control is ideal for testing firing, sintering, and annealing profiles on new materials.

- If your primary focus is semiconductor fabrication: You require highly specialized furnaces, often with vacuum or inert gas capabilities, designed specifically for oxidation, diffusion, and annealing.

- If your primary focus is high-volume assembly: While box furnaces are used for batch soldering, a continuous conveyor-style reflow oven is typically more efficient for mass production lines.

- If your primary focus is ceramic component manufacturing: A high-temperature box furnace designed for the specific sintering profiles of materials like MLCCs or PZT is necessary.

Mastering the use of thermal processing is fundamental to advancing the quality and capability of modern electronic devices.

Summary Table:

| Application | Key Processes | Key Benefits |

|---|---|---|

| Semiconductor Wafer Processing | Oxidation, Diffusion, Annealing | High precision, uniform heating, controlled atmosphere |

| Electronic Ceramics Manufacturing | Sintering, Firing | Material fusion, property enhancement, batch flexibility |

| Component Assembly and Packaging | Reflow Soldering, Brazing | Reliable joints, precise temperature profiles, strong bonds |

Elevate your electronic manufacturing with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide tailored options like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your unique experimental and production needs, whether for semiconductor fabrication, ceramic component production, or assembly processes. Contact us today to discuss how our expertise can optimize your thermal processing and drive innovation in your lab or facility!

Visual Guide

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the function of a high-temperature muffle furnace in HZSM-5 preparation? Master Catalytic Activation

- How is the thermal stability of KBaBi compounds evaluated? Discover Precise XRD & Heat Treatment Limits

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the function of a high-temperature muffle furnace in ZnO-SP preparation? Master Nanoscale Synthesis Control

- Why is a high-temperature muffle furnace used for Ni-BN powder preheating? Achieve defect-free coating density.