In short, box furnaces are used in electronics manufacturing for a wide range of thermal processes, including fabricating semiconductor wafers, producing ceramic components, and assembling circuit boards. Their primary function is to provide a highly controlled heating environment essential for altering the physical and electrical properties of materials, joining parts, and curing adhesives.

The core value of a box furnace in electronics is its ability to deliver precise, repeatable thermal cycles. This control is not just about heating and cooling; it's about fundamentally changing materials at a microscopic level to achieve specific performance characteristics required for modern components.

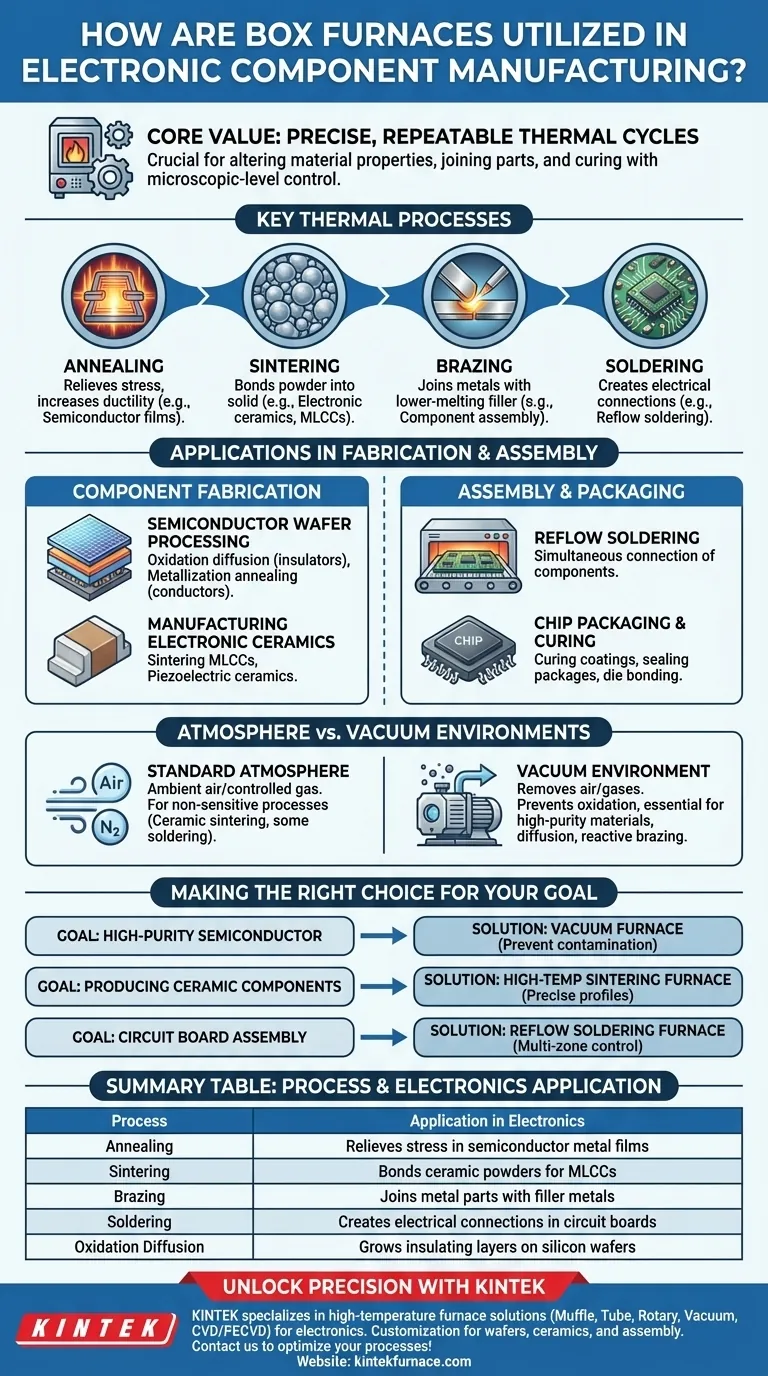

The Critical Role of Thermal Processing

Heat is a fundamental tool in creating electronic components. Applying it with precision allows manufacturers to build structures, alter material properties, and join dissimilar materials together reliably.

A box furnace provides the enclosed, uniform, and tightly regulated environment needed for these sensitive processes, ensuring consistency from one batch to the next.

Defining Key Thermal Processes

- Annealing: This process involves heating and slowly cooling a material, such as a metal film, to relieve internal stresses, increase ductility, and refine its crystalline structure.

- Sintering: Used for ceramics and powdered metals, this involves heating material below its melting point until its particles bond together, forming a solid, dense piece.

- Brazing: A joining process where a filler metal with a lower melting point is used to bond two or more metal parts together inside the furnace.

- Soldering: Similar to brazing but at lower temperatures, this process is used to melt solder and create electrical connections, most notably in reflow soldering for surface-mount components.

Core Applications in Component Fabrication

Before a component ever reaches a circuit board, box furnaces are used to create the fundamental materials and structures it's made from.

Semiconductor Wafer Processing

In the fabrication of integrated circuits, furnaces are used for critical layering and conditioning steps on silicon wafers.

Key applications include oxidation diffusion, where a thin, uniform layer of silicon dioxide (a crucial insulator) is grown on the wafer surface, and metallization annealing, which relieves stress in the thin metal films that form the circuit's conductive pathways.

Manufacturing Electronic Ceramics

Many passive components are built from specialized ceramics. Box furnaces are central to their production.

This includes manufacturing Multilayer Ceramic Capacitors (MLCCs) and piezoelectric ceramics. The process involves sintering layers of ceramic and metallic powders to create the dense, layered structure that gives these components their electrical properties.

Applications in Assembly and Packaging

Once individual dies and components are fabricated, box furnaces play a role in assembling them into finished products.

Reflow Soldering

In modern electronics assembly, box furnaces are used for reflow soldering. Components are placed on a circuit board coated with solder paste, and the entire assembly is passed through a furnace with a carefully controlled temperature profile.

The heat melts the solder, creating strong and reliable electrical connections for all components simultaneously.

Chip Packaging and Curing

Furnaces are also used in various chip packaging steps. This can include curing protective coatings, sealing component packages to protect them from the environment, and bonding the silicon die to its substrate.

Understanding a Key Distinction: Atmosphere vs. Vacuum

Not all furnace environments are the same. The choice between a standard atmosphere and a vacuum is critical and depends entirely on the process requirements.

Standard Atmosphere Furnaces

These furnaces operate with ambient air or a controlled gas mixture (like nitrogen). They are workhorses for processes where oxidation is not a concern or is even desired.

Applications like ceramic sintering and some reflow soldering profiles are commonly performed in standard atmosphere box furnaces.

The Need for a Vacuum Environment

For highly sensitive materials, a vacuum furnace is essential. By removing air and other gases, it prevents unwanted chemical reactions like oxidation.

This is non-negotiable for preparing high-purity electronic materials, performing diffusion on semiconductor wafers, and brazing reactive metals to ensure the integrity and performance of the final component.

Making the Right Choice for Your Goal

The specific type of box furnace and process you need depends directly on your manufacturing objective.

- If your primary focus is high-purity semiconductor processing: You require a vacuum furnace to prevent contamination and ensure the integrity of sensitive layers during oxidation and annealing.

- If your primary focus is producing ceramic components: You need a high-temperature furnace capable of the precise thermal profiles required for sintering materials like MLCCs.

- If your primary focus is circuit board assembly: A conveyor-style box furnace designed for reflow soldering with multi-zone temperature control is the industry standard.

Ultimately, the box furnace is a foundational tool, and mastering its application is essential to achieving the material properties and reliability demanded by modern electronics.

Summary Table:

| Process | Application in Electronics |

|---|---|

| Annealing | Relieves stress in metal films for semiconductors |

| Sintering | Bonds ceramic powders for components like MLCCs |

| Brazing | Joins metal parts with filler metals |

| Soldering | Creates electrical connections in circuit boards |

| Oxidation Diffusion | Grows insulating layers on silicon wafers |

Unlock Precision in Your Electronics Manufacturing with KINTEK

Are you looking to enhance the reliability and performance of your electronic components through advanced thermal processing? At KINTEK, we specialize in providing high-temperature furnace solutions tailored to the unique needs of electronics manufacturers. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by exceptional R&D and in-house manufacturing. With our strong deep customization capability, we can precisely meet your experimental and production requirements, whether you're working on semiconductor wafers, ceramic components, or circuit board assembly.

Don't let thermal inconsistencies hold you back—contact us today to discuss how our furnaces can optimize your processes and drive innovation in your lab!

Visual Guide

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the function of a high-temperature muffle furnace in HZSM-5 preparation? Master Catalytic Activation

- How is the thermal stability of KBaBi compounds evaluated? Discover Precise XRD & Heat Treatment Limits

- What is the function of a high-temperature muffle furnace in ZnO-SP preparation? Master Nanoscale Synthesis Control

- How does high-temperature heating facilitate the conversion of rice husks into inorganic precursors for silica extraction?