Absolutely. You can process metal materials in a rotary kiln without causing nitriding by controlling the internal atmosphere of the furnace. This is achieved by replacing the ambient air, which contains nitrogen, with a chemically non-reactive (inert) gas to protect the material during high-temperature treatment.

Preventing unwanted nitriding is not a limitation of the rotary kiln itself, but a matter of process control. The solution lies in creating a chemically inert environment by purging the furnace with a gas like argon, which requires specific equipment designed for atmosphere integrity.

The Principle of Atmosphere Control

To understand how to prevent nitriding, we must first understand why it happens. The solution is based on displacing the reactive gases that cause the problem.

Why Nitriding Occurs

At elevated temperatures, many metals become highly reactive. The nitrogen that makes up approximately 78% of the air we breathe can chemically bond with these metals, forming metal nitrides. This reaction alters the material's intended chemical and physical properties, which is often an undesirable outcome.

The Role of an Inert Gas

An inert gas, such as argon, is chemically non-reactive under most conditions. By continuously feeding it into the kiln, it displaces the ambient air—including both nitrogen and oxygen. This blankets the metal material in a stable environment, preventing unwanted chemical reactions like nitriding and oxidation from occurring during the heating cycle.

Creating the Inert Environment

The process involves purging the sealed kiln with the inert gas before heating begins to remove all the air. This controlled atmosphere is then maintained at a slight positive pressure throughout the entire heating and cooling process to ensure no outside air can leak back into the system.

Key Equipment Requirements

Achieving a stable, inert atmosphere is not possible in a standard, unsealed kiln. It requires specific design features engineered for this purpose.

High-Integrity Furnace Sealing

This is the most critical feature. A rotary kiln designed for atmosphere control must have specialized sealing structures at both the material inlet and outlet. These seals prevent the expensive inert gas from escaping and, more importantly, stop ambient air from contaminating the internal atmosphere.

Gas Management Systems

The kiln must be equipped with dedicated gas inlet ports to introduce the argon and outlet vents to safely release the displaced air during the initial purge. A precise gas flow control system is essential for maintaining the correct pressure and flow rate throughout the process.

Atmosphere Monitoring

For sensitive applications, systems may include sensors (e.g., an oxygen analyzer) at the gas outlet. These sensors provide real-time data on the purity of the internal atmosphere, verifying that reactive gases like oxygen and nitrogen have been successfully removed and kept below a critical threshold.

Understanding the Trade-offs

While effective, operating with a controlled inert atmosphere involves practical and economic considerations.

Cost of Inert Gas

Inert gases like argon are a significant operational expense. The cost is directly related to the volume of the kiln, the required gas flow rate to maintain purity, and the total processing time.

Equipment Complexity and Maintenance

Rotary kilns with high-integrity sealing systems are more complex and have a higher initial cost. The seals themselves are wear components that require regular inspection and maintenance to ensure they remain effective and prevent costly gas leaks.

Process Validation

Ensuring the complete absence of nitriding requires careful process validation. You must confirm that your gas flow rate and purge times are sufficient to create and maintain the required level of atmospheric purity for your specific material and temperature profile.

How to Apply This to Your Process

Your specific goal will determine the necessary level of control and investment.

- If your primary focus is processing highly sensitive or high-value metals: You must use a high-purity inert gas and a rotary kiln specifically designed with verified, low-leak-rate sealing systems.

- If your primary focus is ensuring process repeatability: Invest in a system with integrated atmosphere monitoring to guarantee that the internal environment is identical for every batch.

- If you are evaluating equipment for purchase: Prioritize kiln manufacturers that can provide documentation on seal design, expected leak rates, and the sophistication of their gas management systems.

Ultimately, successful non-nitriding thermal processing in a rotary kiln hinges on your ability to establish and maintain a pure, inert atmosphere throughout the entire cycle.

Summary Table:

| Key Aspect | Details |

|---|---|

| Method | Use inert gas (e.g., argon) to displace air and prevent nitriding. |

| Equipment Needed | High-integrity seals, gas management systems, atmosphere monitoring. |

| Benefits | Avoids unwanted chemical reactions, maintains material properties. |

| Considerations | Higher cost for gas and equipment, requires maintenance and validation. |

Need a reliable solution for non-nitriding metal processing? KINTEK specializes in advanced high-temperature furnaces, including rotary kilns with superior atmosphere control. Leveraging exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs. Our product line features Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, ensuring precise temperature and gas management for optimal results. Contact us today to discuss how we can enhance your lab's efficiency and achieve consistent, high-quality outcomes!

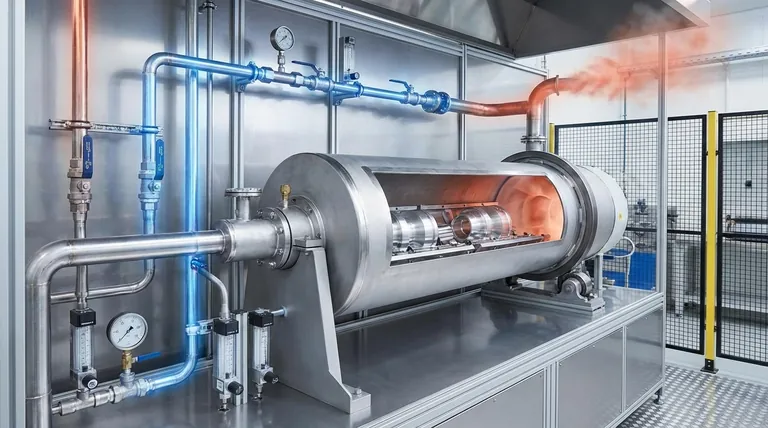

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How does the pressure range change under vacuum conditions in an atmosphere box furnace? Explore Key Shifts for Material Processing

- What are the primary inert gases used in vacuum furnaces? Optimize Your Heat Treatment Process

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas

- How do atmosphere furnaces contribute to ceramic manufacturing? Enhance Purity and Performance

- How is the sealing performance of an experimental box type atmosphere furnace enhanced? Boost Purity with Advanced Sealing Systems