In a controlled atmosphere furnace, uniform atmosphere flow is the single most critical factor for ensuring every part of your material receives the exact same treatment. Without it, the "controlled" environment is merely an illusion, leading to inconsistent gas distribution that undermines the entire process, whether for heat treatment, sintering, or other thermal applications.

The core purpose of uniform flow is to eliminate process variability. It ensures that every surface of your workload is exposed to the same gas composition and temperature, which is the foundation for achieving repeatable, high-quality results and preventing costly product failures.

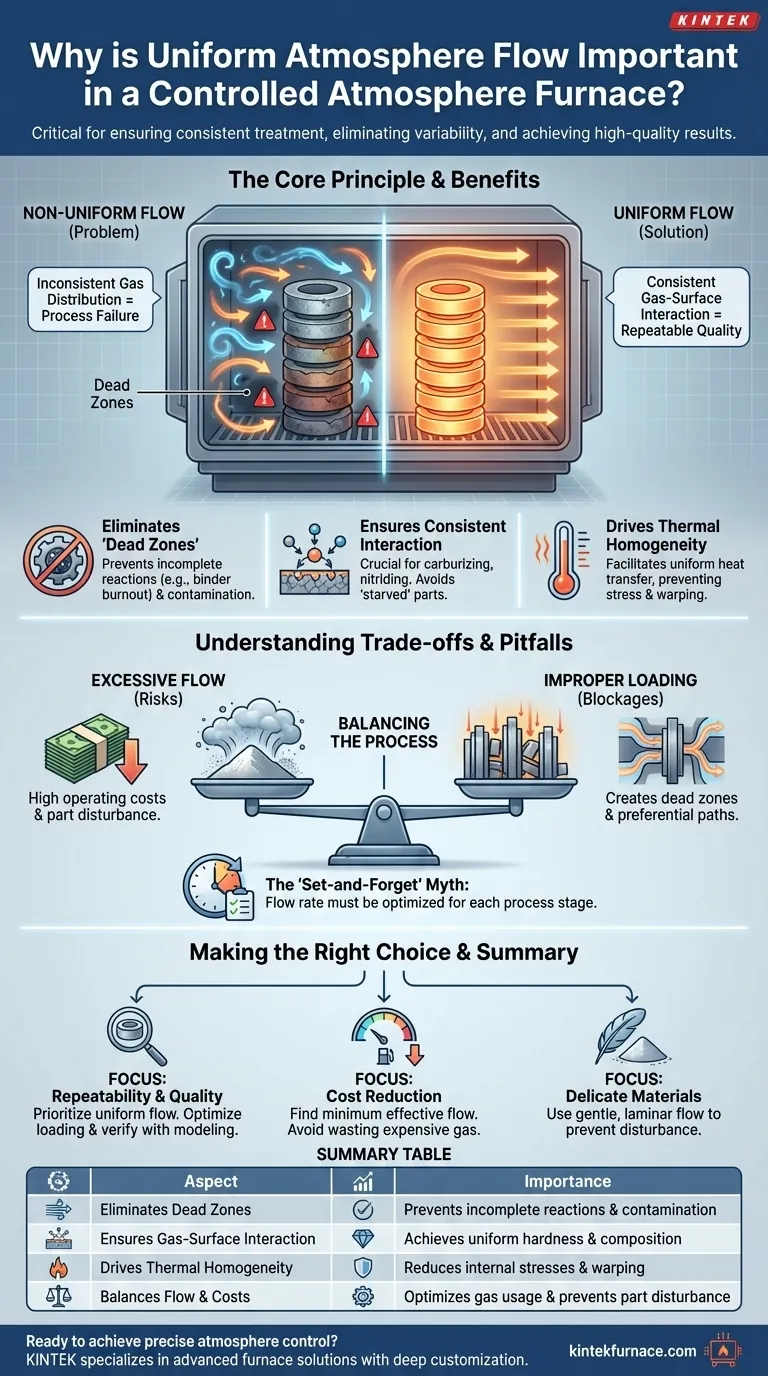

The Core Principle: From Unpredictable to Uniform Processing

A controlled atmosphere is not just about filling a chamber with a specific gas; it's about actively managing how that gas interacts with your material. Uniform flow is the mechanism that ensures this interaction is consistent everywhere.

Eliminating "Dead Zones" and Stagnation

Without proper flow, areas of the furnace can become stagnant. These "dead zones" fail to have their atmosphere replenished effectively.

This leads to incomplete reactions. For example, in a sintering process, binder burnout may be insufficient in a dead zone, leaving behind contaminants that compromise the final part's integrity.

Ensuring Consistent Gas-Surface Interaction

Many thermal processes rely on a chemical reaction at the material's surface. Processes like carburizing, nitriding, or oxidation/reduction depend on a constant supply of reactive gas molecules.

Non-uniform flow means some parts get a fresh supply of gas while others are "starved," resulting in inconsistent surface hardness, case depth, or chemical composition across the batch.

Driving Thermal Homogeneity

The flowing atmosphere is a primary medium for convective heat transfer. Uniform gas flow is essential for achieving uniform temperatures.

High-flow areas can heat or cool faster than stagnant zones, destroying thermal homogeneity. This variation can induce internal stresses, warping, or inconsistent microstructures in the final product.

Understanding the Trade-offs and Common Pitfalls

Achieving perfect uniformity involves balancing several competing factors. More flow is not always better, and the furnace itself is only part of the equation.

The Problem of Excessive Flow

An overly aggressive flow rate can be detrimental. It dramatically increases the consumption of expensive process gases like hydrogen or argon, driving up operating costs.

Furthermore, high-velocity turbulent flow can disturb delicate parts or fine powders, a significant concern in powder metallurgy and metal injection molding (MIM). It can also create localized cooling on part surfaces, working against your goal of thermal uniformity.

The Impact of Furnace Loading

How you load parts into the furnace is as important as the furnace's design. Dense packing creates blockages and preferential flow paths, effectively creating dead zones.

Proper spacing and orientation of the workload are critical for allowing the atmosphere to circulate freely around every single part. The best furnace design can be defeated by improper loading.

The Myth of a "Set-and-Forget" Flow Rate

There is no single universal flow rate. The ideal rate depends on the specific process, the material's outgassing rate (e.g., during binder burnout), and the furnace's load size.

Effective atmosphere control requires optimizing the flow rate for each stage of the thermal cycle to ensure efficiency and process success.

Making the Right Choice for Your Process

Applying these principles correctly depends entirely on your primary objective. Your approach to atmosphere flow should be tailored to your specific process goals.

- If your primary focus is process repeatability and quality: Treat uniform flow as a non-negotiable requirement. Invest time in optimizing loading patterns and verifying flow with modeling or diagnostics to eliminate product variation.

- If your primary focus is cost reduction: Optimize your flow rates for each process step. Find the minimum effective flow that maintains uniformity to avoid wasting expensive gas and reduce energy consumption from shorter cycle times.

- If you are processing delicate materials or powders: Prioritize gentle, laminar flow over high-velocity, turbulent flow. The goal is to ensure complete atmosphere exchange without physically disturbing the workload.

Mastering atmosphere control transforms your furnace from a simple oven into a precision instrument for material engineering.

Summary Table:

| Aspect | Importance |

|---|---|

| Eliminates Dead Zones | Prevents incomplete reactions and contamination |

| Ensures Gas-Surface Interaction | Achieves uniform hardness and composition |

| Drives Thermal Homogeneity | Reduces internal stresses and warping |

| Balances Flow and Costs | Optimizes gas usage and prevents part disturbance |

Ready to achieve precise and uniform atmosphere control in your lab? At KINTEK, we specialize in advanced high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With our strong R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs—ensuring consistent results, reduced costs, and enhanced process repeatability. Contact us today to discuss how our tailored solutions can optimize your thermal processes!

Visual Guide

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What are the two main types of atmosphere furnaces and their characteristics? Choose the Right Furnace for Your Lab

- What industries commonly use inert atmosphere heat treating? Key Applications in Military, Automotive, and More

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- Why is moisture control critical in inert atmosphere heat treating? Prevent Oxidation and Ensure Material Integrity