In modern dental prosthetics, programmability is not a luxury; it is a clinical necessity. It is the feature that gives a dental laboratory precise control over the heating and cooling cycles required to process advanced restorative materials. This capability is essential for accommodating the unique chemical and physical properties of different ceramics, ensuring the final restoration has the required strength, aesthetics, and fit.

Programmability transforms a dental furnace from a simple oven into a precision instrument. It directly addresses the core challenge of modern dentistry: achieving consistent, high-quality results across an ever-expanding landscape of restorative materials, each with its own unique processing demands.

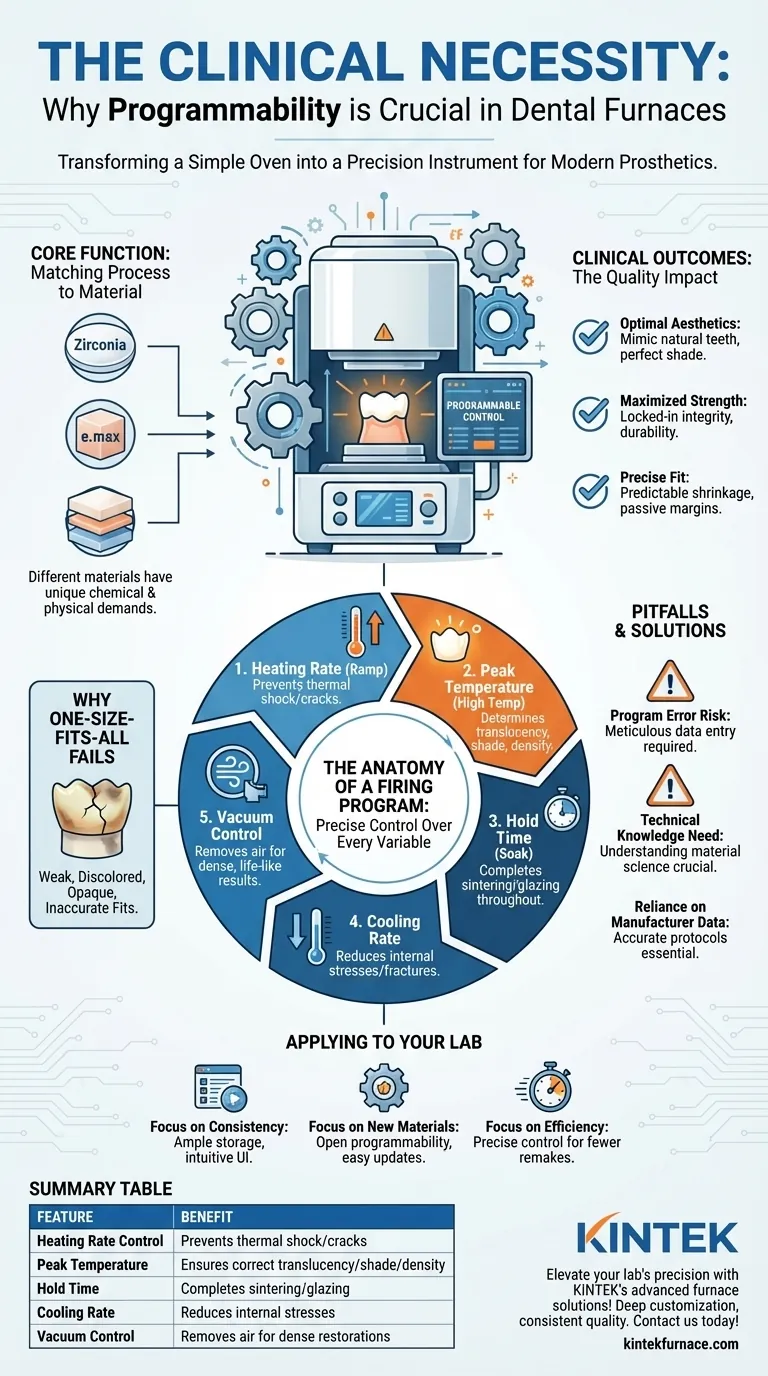

The Core Function: Matching the Process to the Material

The fundamental purpose of a programmable furnace is to execute a precise, time-based temperature plan. This is critical because different dental materials react to heat in vastly different ways.

Why One-Size-Fits-All Firing Fails

Using a generic or incorrect firing cycle is a primary cause of failed restorations. Materials like zirconia, lithium disilicate (e.max), and layered porcelains have unique requirements for temperature and time. Applying the wrong program can lead to a restoration that is weak, discolored, opaque, or dimensionally inaccurate.

The Anatomy of a Firing Program

Programmability allows a technician to control every critical variable of the thermal process. This is what separates a successful outcome from a costly remake.

- Heating Rate (Ramp Rate): This defines how quickly the temperature rises. A rate that is too fast can induce thermal shock, causing cracks in the ceramic.

- Peak Temperature (High Temp): The maximum temperature reached during the cycle. Even a deviation of a few degrees can dramatically alter a material's translucency, shade, and density.

- Hold Time (Soak Time): The duration the material is held at its peak temperature. This ensures processes like sintering (for zirconia) or glazing are completed throughout the entire restoration, not just on the surface.

- Cooling Rate: The speed at which the furnace cools is just as critical as the heating rate. Cooling too quickly can create internal stresses that lead to delayed fractures after the crown is seated.

- Vacuum Control: For porcelain applications, a vacuum is used during heating to remove air and prevent porosity. Programmability dictates precisely when the vacuum starts and stops, which is key to achieving a dense, life-like restoration.

The Impact on Clinical Outcomes

The control offered by programmability directly influences the quality of the final product that reaches the patient.

Ensuring Optimal Aesthetics

The final shade and translucency of a ceramic crown are not determined solely by the material itself. They are developed during the firing process. Precise temperature control is what allows a technician to achieve the exact level of translucency needed to mimic a natural tooth.

Maximizing Material Strength

The structural integrity of a ceramic restoration is locked in during its final firing or sintering cycle. An incomplete cycle due to incorrect hold times or temperatures results in a porous, weak material. A programmable furnace ensures the manufacturer's scientifically validated protocols are followed, maximizing the material's flexural strength and long-term durability in the mouth.

Guaranteeing a Precise Fit

Improper heating can cause restorations to warp or shrink unpredictably. This results in crowns that do not seat correctly, leading to open margins, chairside frustration for the dentist, and the need for a complete remake by the lab. Reproducible programs guarantee predictable shrinkage and a passive, accurate fit.

Understanding the Pitfalls and Limitations

While essential, programmability is not a magic bullet and comes with its own set of considerations.

The Risk of Program Error

With great control comes the potential for human error. Entering the wrong parameter—mistaking a 9 for a 6 in a temperature setting, for example—can ruin an entire batch of restorations. Meticulous data entry and verification are crucial.

The Need for Technical Knowledge

Effectively using a programmable furnace requires a solid understanding of material science. Technicians must know why a certain heating rate is recommended and what impact their adjustments will have. Simply downloading programs without understanding them can be a risky endeavor.

Reliance on Manufacturer Data

Labs are heavily dependent on ceramic manufacturers to provide accurate and updated firing schedules. If the manufacturer's data is flawed, even a perfectly executed program will produce a suboptimal result.

How to Apply This to Your Laboratory

Your choice and use of a programmable furnace should be guided by your lab's specific goals.

- If your primary focus is consistency across multiple materials: Prioritize a furnace with ample program storage and an intuitive user interface to minimize errors when switching between materials like zirconia and lithium disilicate.

- If your primary focus is adopting new, advanced ceramics: Invest in a furnace with open programmability, allowing you to easily create, test, and modify cycles based on manufacturer updates and future material releases.

- If your primary focus is efficiency and reducing remakes: Ensure the furnace offers precise control over all stages, especially cooling rates and vacuum levels, as these are critical for preventing costly failures with sensitive materials.

Ultimately, mastering furnace programmability empowers you to take full control of the final outcome, turning raw materials into predictable and high-quality clinical results.

Summary Table:

| Feature | Benefit |

|---|---|

| Heating Rate Control | Prevents thermal shock and cracks in ceramics |

| Peak Temperature | Ensures correct translucency, shade, and density |

| Hold Time | Completes sintering or glazing for full strength |

| Cooling Rate | Reduces internal stresses to avoid fractures |

| Vacuum Control | Removes air for dense, life-like restorations |

Elevate your dental lab's precision and efficiency with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature furnace systems, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure your unique experimental needs are met, helping you achieve consistent, high-quality restorations with materials like zirconia and ceramics. Contact us today to discuss how our solutions can optimize your workflow and reduce remakes!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab