In short, precise temperature control is the single most critical factor in determining the strength, fit, and aesthetics of a final dental porcelain restoration. It is the mechanism that ensures the ceramic material transforms from a fragile powder into a dense, life-like, and durable final product according to its exact specifications.

The core issue is not simply reaching a peak temperature, but flawlessly executing the entire temperature journey—the firing curve. Each type of porcelain has a unique "recipe" of heating, holding, and cooling stages, and any deviation can compromise the material's structural integrity and visual properties.

The Science Behind Porcelain Transformation

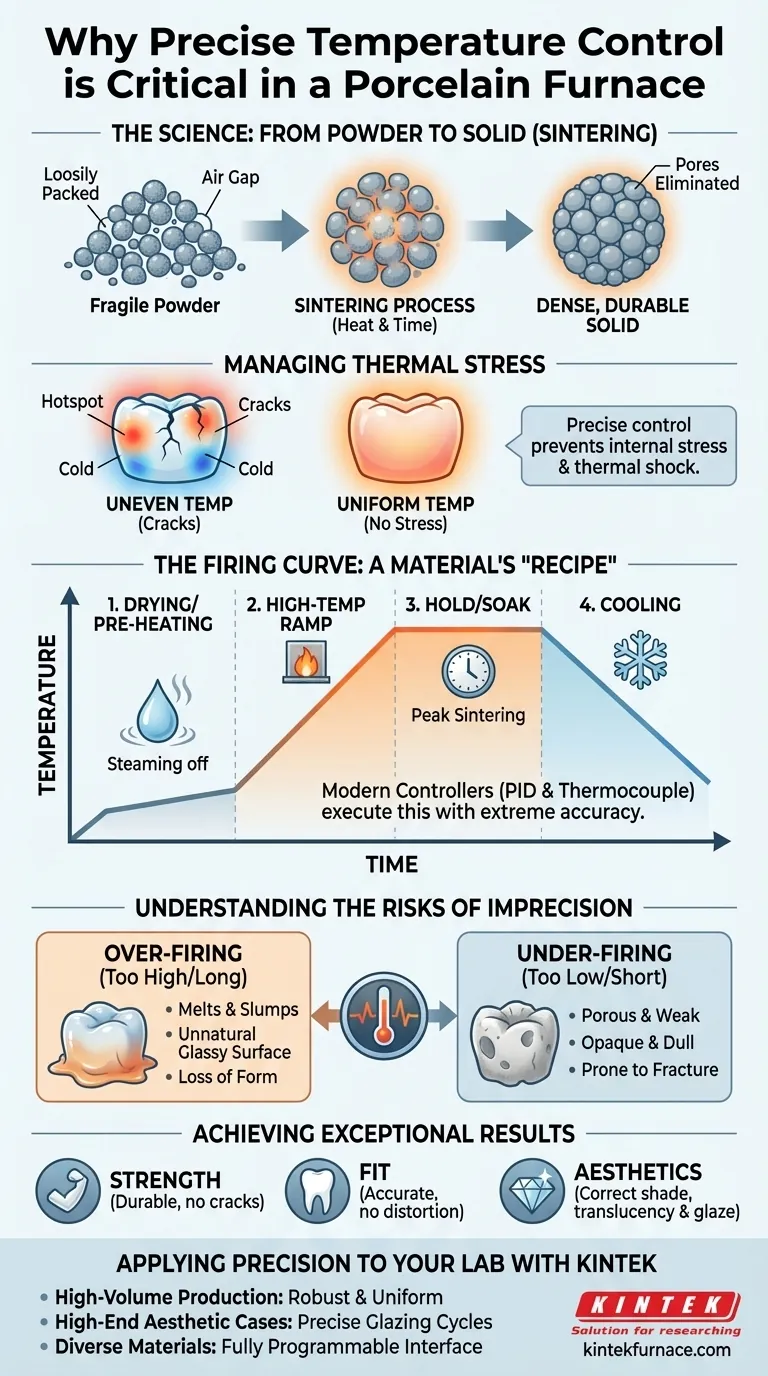

To understand the importance of temperature control, you must first understand what happens to porcelain powder inside the furnace. The goal is a process called sintering, where individual particles fuse together without melting.

From Powder to Solid: The Sintering Process

Sintering is the microscopic bonding of ceramic particles. As the temperature rises, the atoms on the surfaces of these particles become more active.

At the correct sintering temperature, the particles bond at their contact points, eliminating the empty spaces (pores) between them. This process is what gives the final restoration its density and strength.

Managing Thermal Stress

Porcelain is a brittle material that is highly susceptible to thermal shock. If heated or cooled too quickly, different parts of the restoration will expand or contract at different rates.

This uneven temperature distribution creates internal stress, which can lead to microscopic or even visible cracks. Precise control ensures the temperature rises and falls at a slow, deliberate rate, allowing the entire piece to heat and cool uniformly.

Achieving Final Aesthetics and Fit

The final appearance of a restoration—its translucency, shade, and surface glaze—is directly tied to the firing cycle.

The glaze fire is a separate, often lower-temperature cycle that melts a thin surface layer to create a smooth, glossy, and non-porous surface. Even a deviation of a few degrees can mean the difference between a natural-looking luster and a dull, or overly glassy, finish.

Furthermore, improper heating can cause the porcelain to slump or distort, ruining the meticulous fit required for a successful crown or bridge.

The Firing Curve: A Material's "Recipe"

Every dental ceramic comes with a manufacturer-specified firing curve. This is not just a single temperature, but a detailed graph of temperature over time that the furnace must follow perfectly.

What is a Firing Curve?

A typical firing curve includes several key stages:

- Drying/Pre-heating: A slow initial ramp to remove all moisture, which would otherwise turn to steam and destroy the restoration.

- High-Temperature Ramp: A controlled increase to the peak sintering temperature.

- Hold/Soak: A period where the furnace maintains the peak temperature to ensure complete sintering throughout the porcelain.

- Cooling: A controlled temperature decrease to prevent thermal shock.

The Role of Modern Controllers

Modern furnaces use a thermocouple (a highly sensitive temperature sensor) and a PID controller (Proportional-Integral-Derivative) to achieve this precision.

The controller constantly compares the actual chamber temperature to the target temperature in the firing curve. It then makes thousands of micro-adjustments to the heating elements every minute to stay on the prescribed path with extreme accuracy.

Understanding the Risks of Imprecision

Investing in a furnace with precise control is an investment in predictability and quality. The consequences of poor control are costly and immediate.

The Consequence of Over-firing

If the temperature is too high or held for too long, the porcelain can begin to melt instead of just sinter.

This leads to a loss of anatomical form ("slumping"), increased translucency that looks unnatural and gray, and a glassy surface that is difficult to polish or characterize. The restoration is often a complete failure.

The Consequence of Under-firing

If the temperature does not get high enough or the hold time is too short, the sintering process is incomplete.

The resulting restoration will be porous, weak, and opaque. It will be prone to fracture under chewing forces and will lack the vitality of natural teeth.

The Impact of Chamber Uniformity

Precise control of the firing curve is meaningless if the temperature isn't the same throughout the firing chamber.

A high-quality furnace ensures uniform heating, so a restoration placed in the front of the chamber fires identically to one placed in the back. Inconsistent heating leads to inconsistent results, even within the same firing cycle.

How to Apply This to Your Goal

Your choice of furnace and how you use it should be directly linked to the outcomes you need to achieve.

- If your primary focus is high-volume, repeatable production: Prioritize furnaces with a reputation for robust controllers and exceptional temperature uniformity to ensure every unit in a batch is identical.

- If your primary focus is high-end, complex aesthetic cases: Select a furnace known for its precise control of glazing cycles and its ability to manage complex, multi-stage firing programs for advanced layered ceramics.

- If your primary focus is working with new or diverse materials: Choose a furnace with a fully programmable interface that allows you to easily create, store, and execute the unique firing curves required by different ceramic systems.

Ultimately, precise temperature control transforms the firing process from an art of approximation into a science of predictable, exceptional results.

Summary Table:

| Aspect | Impact of Precise Control |

|---|---|

| Strength | Prevents porosity and cracking for durable restorations |

| Fit | Avoids distortion and slump for accurate dental fits |

| Aesthetics | Achieves correct translucency, shade, and glaze finish |

| Process | Enables exact sintering and thermal stress management |

Upgrade your dental lab with KINTEK's precision furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures your unique experimental needs are met for flawless porcelain restorations. Contact us today to discuss how our furnaces can enhance your quality and efficiency!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- What is the sintering process in dentistry? Unlock the Strength of Zirconia Restorations