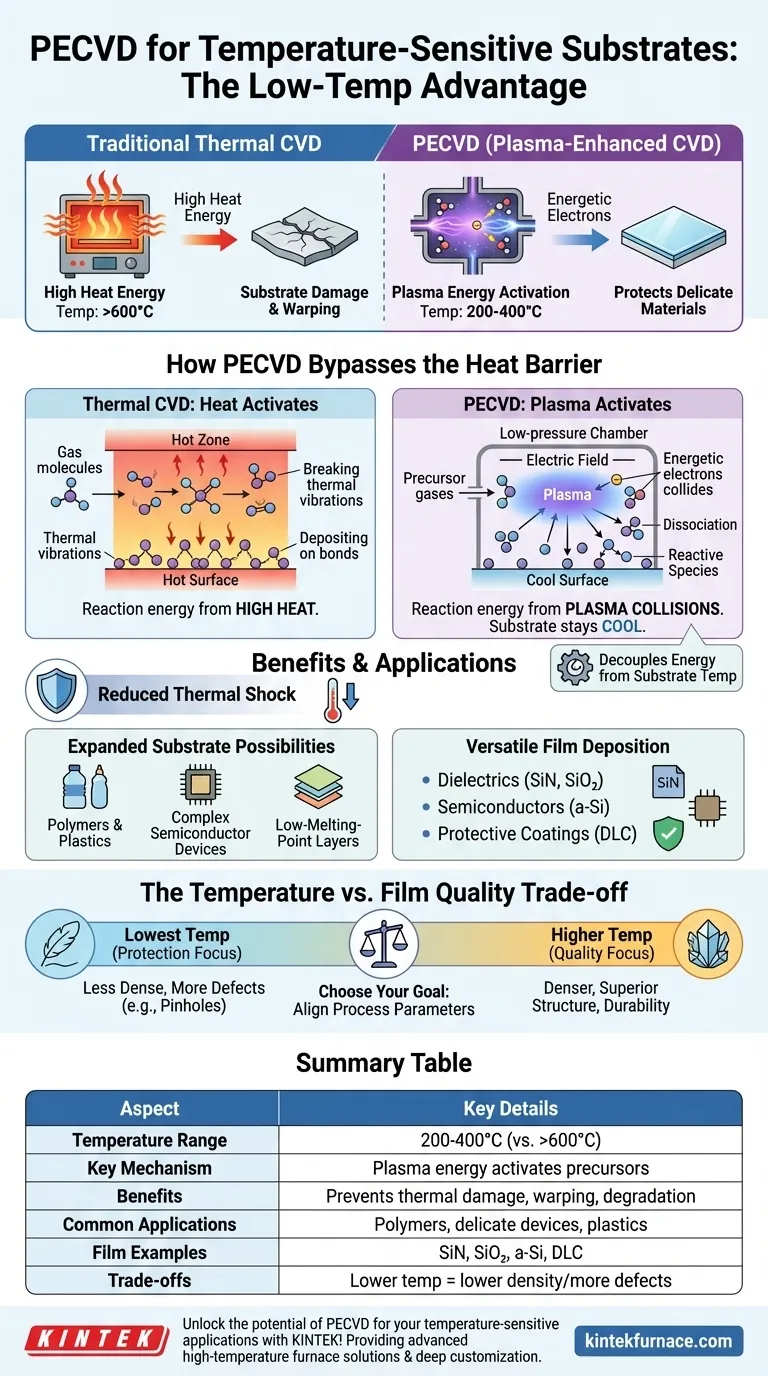

At its core, Plasma-Enhanced Chemical Vapor Deposition (PECVD) is uniquely suited for temperature-sensitive substrates because it substitutes intense heat with plasma energy. This fundamental difference allows it to drive the chemical reactions needed for film deposition at significantly lower temperatures (typically 200-400°C) compared to traditional Chemical Vapor Deposition (CVD), which often requires 600°C or more. This prevents thermal damage, warping, or degradation of delicate materials.

The critical advantage of PECVD is its ability to decouple the reaction energy from the substrate's temperature. By using an energized plasma to break down precursor gases instead of high heat, it enables high-quality coating on materials that would otherwise be destroyed by conventional deposition processes.

How PECVD Bypasses the High-Temperature Barrier

The Role of Plasma, Not Heat

In traditional thermal CVD, high temperatures are essential. This heat provides the raw energy needed to break the chemical bonds of the precursor gases, allowing them to react and form a solid film on the substrate surface.

PECVD creates this energy in a completely different way. It introduces precursor gases into a low-pressure chamber and then applies an electric field, igniting the gas into a plasma.

Activating Precursors with Plasma Energy

This plasma is a highly energetic state of matter containing free electrons, ions, and neutral radicals. The energetic electrons collide with the precursor gas molecules, breaking them apart.

This process, known as dissociation, creates the reactive chemical species needed for deposition. Because the energy comes from the plasma collisions rather than thermal vibration, the substrate itself can remain at a much lower temperature.

Reducing Thermal Shock

Beyond just the peak temperature, PECVD also protects substrates by minimizing thermal shock. The gradual, low-temperature process avoids the rapid temperature changes that can cause sensitive materials like glass or pre-processed semiconductor wafers to crack or delaminate.

The Practical Impact on Materials and Applications

Expanding Substrate Possibilities

The low-temperature nature of PECVD unlocks the ability to deposit films on a vast range of heat-sensitive substrates. This includes materials like polymers, plastics, and complex semiconductor devices that already contain delicate, low-melting-point metallic layers.

Depositing a Versatile Range of Films

PECVD is not limited to a niche set of materials. It is a workhorse for depositing many of the most critical films used in modern technology.

Common examples include:

- Dielectrics: Silicon Nitride (SiN) and Silicon Dioxide (SiO₂) for electrical insulation.

- Semiconductors: Amorphous Silicon (a-Si) and Microcrystalline Silicon for solar cells and transistors.

- Protective Coatings: Diamond-Like Carbon (DLC) for exceptional wear resistance.

Understanding the Trade-offs: Temperature vs. Film Quality

While PECVD is a low-temperature process, it is a mistake to assume that temperature no longer matters. A critical trade-off exists between the deposition temperature and the final quality of the film.

The Benefits of Higher Temperatures

Even within the PECVD window, operating at a higher temperature (e.g., 350-400°C) generally yields a superior film. The added thermal energy helps atoms on the surface arrange themselves into a denser, more ordered structure.

These films typically exhibit lower hydrogen content, higher density, and slower etch rates, which are all indicators of a high-quality, durable coating.

The Risks of Lower Temperatures

When depositing at the lowest possible temperatures to protect an extremely sensitive substrate, the quality of the film can be compromised.

These low-temperature films are often less dense and may be more prone to defects like pinholes. This occurs because the deposited atoms have insufficient energy to move around and settle into an ideal structure, leaving microscopic voids.

Making the Right Choice for Your Goal

To apply PECVD effectively, you must align the process parameters with your primary objective.

- If your primary focus is protecting a highly sensitive substrate: Operate at the lowest possible temperature and accept that the resulting film may have lower density or more defects as a necessary compromise.

- If your primary focus is achieving the highest film quality: Use the highest temperature your substrate can safely tolerate within the PECVD process window to produce a denser, more robust film.

- If your primary focus is depositing on a robust substrate (e.g., silicon or quartz): You have the flexibility to optimize for film quality by using higher PECVD temperatures or even considering if a non-plasma, thermal CVD process could offer superior properties.

By understanding that PECVD replaces heat with plasma energy, you can strategically control the process to achieve the ideal balance between substrate integrity and film performance.

Summary Table:

| Aspect | Key Details |

|---|---|

| Temperature Range | 200-400°C, significantly lower than traditional CVD (≥600°C) |

| Key Mechanism | Uses plasma energy instead of high heat to activate precursors |

| Benefits | Prevents thermal damage, warping, and degradation of substrates |

| Common Applications | Deposition on polymers, plastics, and delicate semiconductor devices |

| Film Examples | Silicon Nitride (SiN), Silicon Dioxide (SiO₂), Amorphous Silicon (a-Si) |

| Trade-offs | Lower temperatures may reduce film density and increase defects like pinholes |

Unlock the potential of PECVD for your temperature-sensitive applications with KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature furnace solutions, including CVD/PECVD Systems, tailored for diverse laboratories. Our strong deep customization capability ensures we precisely meet your unique experimental needs, from protecting delicate substrates to achieving superior film quality. Contact us today to discuss how our solutions can enhance your research and production processes!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- How does plasma vapor deposition work? A Low-Temperature Solution for Advanced Coatings

- What is PECVD and how does it differ from traditional CVD? Unlock Low-Temperature Thin Film Deposition

- What is PECVD equipment? A Guide to Low-Temperature Thin-Film Deposition

- What gases are used in the PECVD system? Optimize Thin Film Deposition with Precise Gas Selection

- What is plasma enhanced chemical vapor deposition application? Enable High-Performance Thin Films at Lower Temperatures