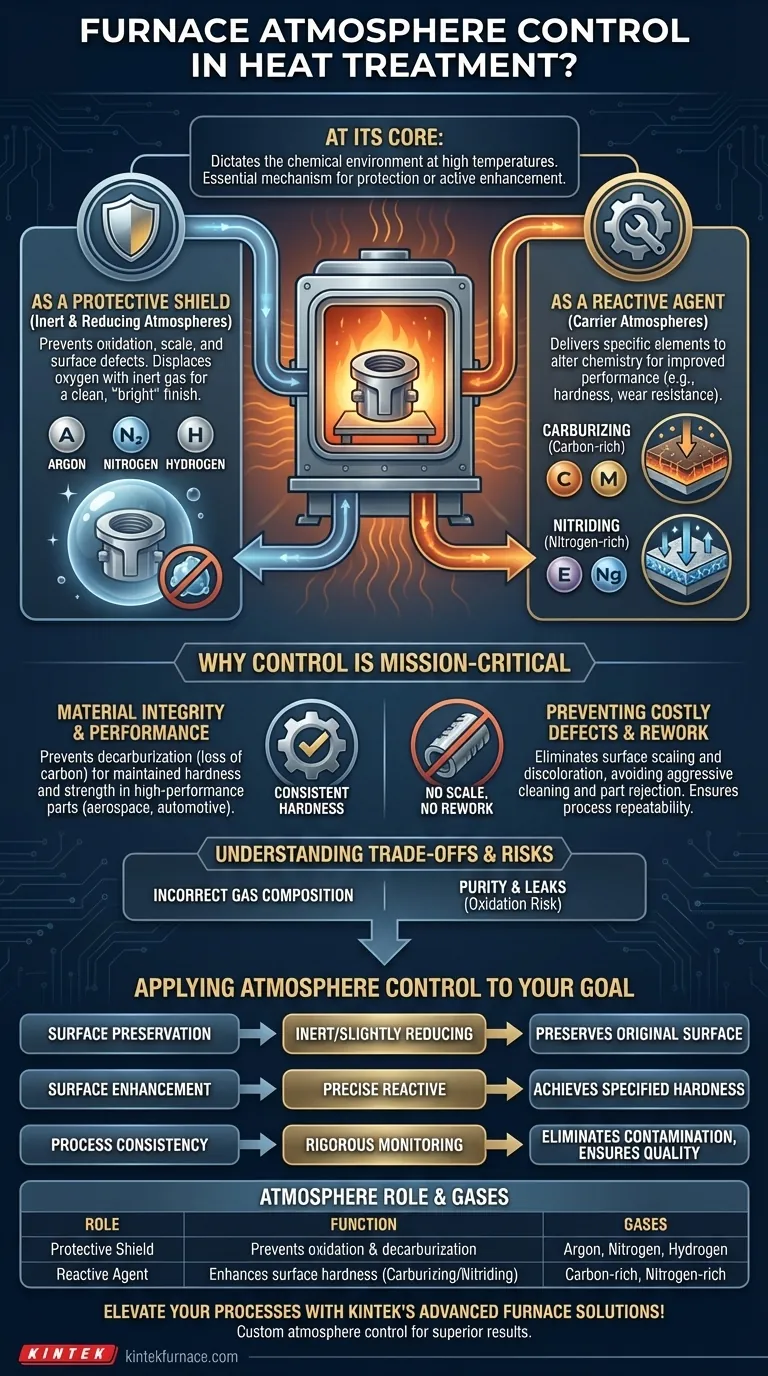

At its core, furnace atmosphere control is essential in heat treatment because it dictates the chemical environment surrounding a part at high temperatures. This control is not optional; it is the mechanism that either protects a component from catastrophic damage like oxidation or actively drives specific chemical reactions to enhance its surface properties, such as hardness.

The central purpose of furnace atmosphere control is to manage the chemical reactions on a component's surface. It serves two distinct roles: acting as a protective shield against unwanted reactions or as a reactive carrier to deliberately change the material's surface for improved performance.

The Two Fundamental Roles of a Furnace Atmosphere

To understand its importance, you must see the atmosphere as an active tool, not just empty space. Its composition determines its function, which falls into two primary categories.

As a Protective Shield (Inert & Reducing Atmospheres)

At elevated temperatures, metals like steel become highly reactive with oxygen in the air. This reaction, known as oxidation, creates scale, discoloration, and surface defects that can compromise the part's integrity.

A protective atmosphere acts as a barrier, preventing this damage. By filling the furnace with an inert gas (like argon or nitrogen) or a reducing gas (like hydrogen), oxygen is displaced, effectively shielding the hot component from harm and ensuring a clean, "bright" finish.

As a Reactive Agent (Carrier Atmospheres)

In many processes, the goal is not just to protect the surface but to intentionally change it. Here, the atmosphere acts as a carrier, delivering specific elements to the component's surface to alter its chemistry.

Processes like carburizing use a carbon-rich atmosphere to infuse carbon into the surface of steel, creating a very hard, wear-resistant outer layer while keeping the core ductile. Similarly, nitriding uses a nitrogen-rich atmosphere to achieve similar hardening effects. In these cases, the atmosphere is a critical ingredient in the metallurgical recipe.

Why This Control is Mission-Critical

The consequences of poor atmosphere control range from cosmetic blemishes to catastrophic component failure. For mission-critical parts in aerospace, automotive, or medical industries, precision is non-negotiable.

Ensuring Material Integrity and Performance

An uncontrolled atmosphere can lead to decarburization—the loss of carbon from a steel's surface—which makes the part softer and weaker than specified. For a high-performance gear or bearing, this reduction in surface hardness can lead to premature failure in the field.

Preventing Costly Defects and Rework

Poor atmosphere control is a direct cause of rejected parts. Surface scaling requires aggressive and costly cleaning operations that can alter a part's final dimensions. Discoloration may not affect performance but can lead to rejection on cosmetic grounds. Precise control eliminates this waste and ensures process repeatability.

Understanding the Trade-offs and Risks

Achieving the correct atmosphere is a technical challenge with clear risks. The choice of gas and the integrity of the furnace system are paramount.

The Risk of Incorrect Gas Composition

The gas mixture must be perfectly matched to the material and the process. Using a strongly reducing hydrogen atmosphere on certain steels can unintentionally strip carbon from the surface (decarburization), undermining the part's strength. The atmosphere must be a prescription, not a generic solution.

The Challenge of Purity and Leaks

The system's integrity is just as important as the gas supply. Even a small air leak into the furnace can introduce enough oxygen to contaminate an inert atmosphere, causing oxidation across an entire batch of high-value components. Continuous monitoring with gas analyzers is essential to guard against this.

Applying Atmosphere Control to Your Goal

The right atmospheric strategy depends entirely on the desired outcome of your heat treatment process.

- If your primary focus is surface preservation (e.g., bright annealing, neutral hardening): Your goal is a perfectly inert or slightly reducing atmosphere that prevents any chemical reaction, preserving the part's original surface.

- If your primary focus is surface enhancement (e.g., carburizing, nitriding): Your goal is a precisely controlled reactive atmosphere that consistently delivers the necessary elements to achieve the specified surface hardness and case depth.

- If your primary focus is process consistency: Your goal is rigorous monitoring and maintenance of the entire system—from gas purity to furnace seals—to eliminate contamination and ensure repeatable, high-quality results.

Ultimately, mastering the furnace atmosphere is mastering the final properties and quality of the component itself.

Summary Table:

| Role of Atmosphere | Key Functions | Common Gases Used |

|---|---|---|

| Protective Shield | Prevents oxidation and decarburization | Argon, Nitrogen, Hydrogen |

| Reactive Agent | Enhances surface hardness via carburizing/nitriding | Carbon-rich gases, Nitrogen-rich gases |

Elevate your heat treatment processes with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our deep customization capability ensures precise atmosphere control to meet your unique experimental needs, preventing defects and enhancing material performance. Contact us today to discuss how we can optimize your setup for superior results!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What are the key features of an atmosphere box furnace? Unlock Precise Heat Processing in Controlled Environments

- How does a batch type controlled atmosphere furnace operate? Master Precision Heat Treatment for Superior Materials

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas

- What are the primary inert gases used in vacuum furnaces? Optimize Your Heat Treatment Process

- What are the development prospects of atmosphere box furnaces in the aerospace industry? Unlock Advanced Material Processing for Aerospace Innovation