At its core, energy efficiency in an induction melting furnace is a direct lever on operational cost and profitability. Because these furnaces are significant power consumers, a more efficient unit directly translates to lower electricity bills. This reduction in energy consumption not only yields substantial long-term cost savings but also delivers crucial environmental benefits by lowering your operation's carbon footprint.

While the immediate benefit of an energy-efficient furnace is a lower power bill, its true value lies in how efficiency impacts overall productivity, melt quality, and long-term scalability. It is not just a feature, but a foundational element of a modern, competitive melting operation.

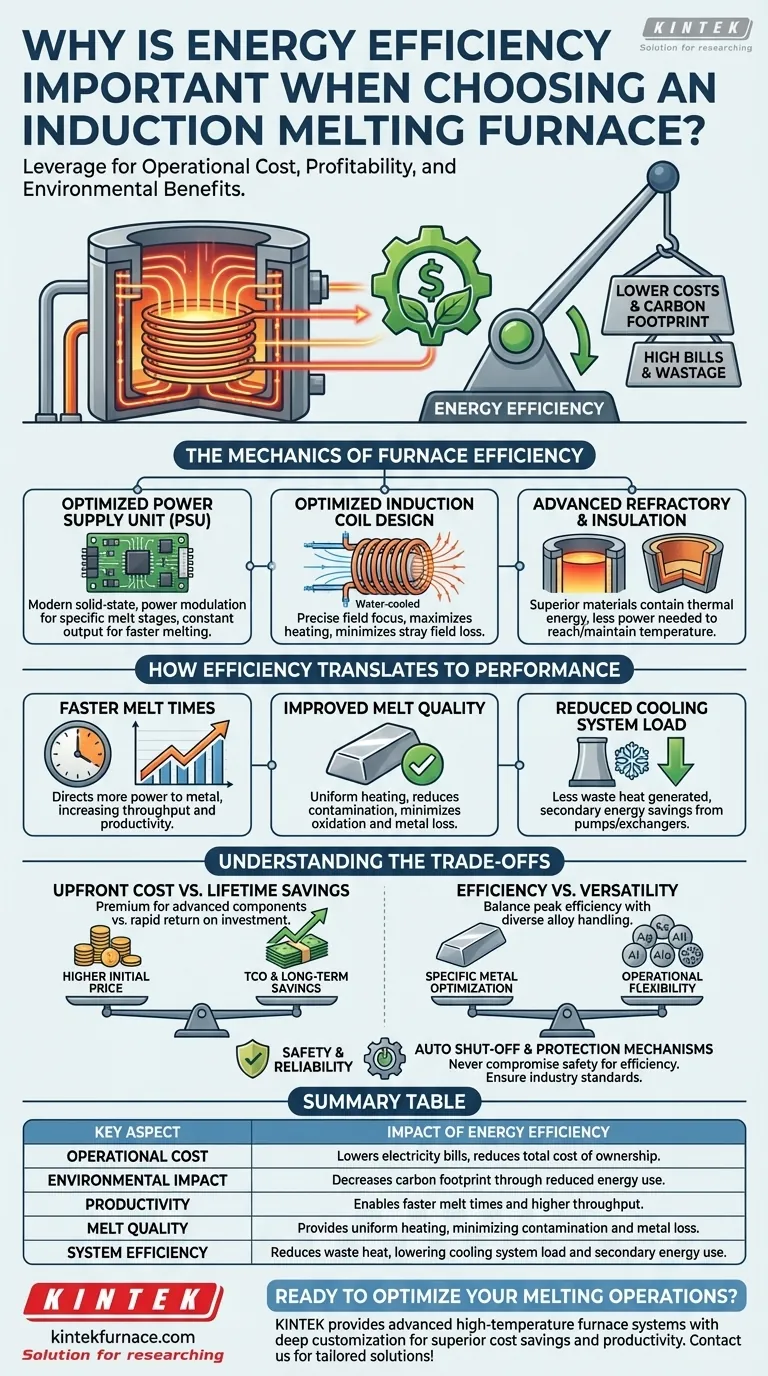

The Mechanics of Furnace Efficiency

Understanding where energy is used—and saved—requires looking at the core components of the furnace system. Modern efficiency gains are not from a single breakthrough but from the optimization of the entire system working in concert.

The Power Supply Unit (PSU)

The PSU is the heart of the furnace, converting standard grid electricity into the high-frequency AC power needed to generate the magnetic field. Modern solid-state power supplies are vastly more efficient than older technologies.

They enable features like power modulation, which adjusts energy output to the specific stage of the melt, and maintain a constant power output, which leads directly to faster, more predictable melting speeds.

Optimized Induction Coil Design

The water-cooled copper induction coil is where energy is converted into a powerful magnetic field. The efficiency of this transfer is paramount.

A well-engineered coil focuses the magnetic field precisely on the metal charge. This ensures maximum energy is absorbed by the metal for heating and minimizes energy lost as stray electromagnetic fields, resulting in a more effective melt.

Advanced Refractory and Insulation

Every bit of heat that escapes the crucible is wasted energy. High-efficiency furnaces use superior refractory materials and insulation to contain thermal energy within the melt.

This simple but critical feature means less power is required to reach and maintain the target temperature, directly reducing kilowatt-hour consumption during every cycle.

How Efficiency Translates to Performance

Energy efficiency isn't just an abstract number; it has tangible effects on your daily operations and the quality of your final product.

Faster Melt Times

An efficient furnace directs more power into the metal. This results in faster heating and shorter melt times, which directly increases your plant's productivity and throughput.

For industrial-scale operations, shaving minutes off each melt cycle can add up to hours of additional production time over a week.

Improved Melt Quality

Efficiency is closely linked to control. A well-designed system provides uniform heating, ensuring the entire metal charge reaches temperature simultaneously.

This consistency reduces the risk of contamination from overheating, minimizes metal loss due to oxidation, and produces a more homogeneous final product.

Reduced Cooling System Load

Inefficiency manifests as waste heat, which the furnace's closed-loop water cooling system must then remove. A more efficient furnace generates less waste heat.

This reduces the load on the cooling system, leading to secondary energy savings from pumps and heat exchangers, as well as lower water consumption.

Understanding the Trade-offs

Choosing a furnace requires a holistic view. The most energy-efficient option may not be the perfect solution without considering other critical factors.

Upfront Cost vs. Lifetime Savings

High-efficiency furnaces often carry a higher initial purchase price due to their advanced components. However, this premium is an investment.

You must calculate the total cost of ownership (TCO), factoring in the long-term energy savings, which can often provide a rapid return on the initial investment.

Efficiency vs. Versatility

Some furnace designs are highly optimized for a specific metal and charge size to achieve peak efficiency. This specialization can sometimes come at the cost of flexibility.

If your operation handles a wide variety of alloys or batch sizes, you must balance the need for peak efficiency with the need for operational versatility.

Don't Overlook Safety and Reliability

The pursuit of efficiency must never compromise safety. Ensure any furnace you consider meets all industry safety standards, with features like automatic shut-off systems and emergency stops.

Likewise, reliability is key. Furnaces with comprehensive protection mechanisms against over-voltage, over-current, and water shortages ensure uptime and protect the equipment from damage, safeguarding your investment.

Making the Right Choice for Your Operation

The ideal furnace depends entirely on your specific operational goals. Use these points to guide your decision-making process.

- If your primary focus is maximizing throughput: Prioritize a furnace with constant high-power output and a proven track record of rapid melting capabilities.

- If your primary focus is minimizing operational cost: Scrutinize the power supply efficiency ratings and the quality of the insulation to reduce long-term energy consumption.

- If your primary focus is long-term growth: Select a scalable system that maintains its efficiency across a range of production demands to avoid future replacement costs.

- If your primary focus is melting diverse or sensitive alloys: Ensure the furnace's precise temperature control and uniform heating capabilities are sufficient for your metallurgical needs.

Ultimately, choosing the right furnace is about investing in a system where energy efficiency drives not just savings, but overall operational excellence.

Summary Table:

| Key Aspect | Impact of Energy Efficiency |

|---|---|

| Operational Cost | Lowers electricity bills, reduces total cost of ownership |

| Environmental Impact | Decreases carbon footprint through reduced energy use |

| Productivity | Enables faster melt times and higher throughput |

| Melt Quality | Provides uniform heating, minimizing contamination and metal loss |

| System Efficiency | Reduces waste heat, lowering cooling system load and secondary energy use |

Ready to optimize your melting operations with energy-efficient solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace systems, including Induction Melting Furnaces, Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental and production needs, helping you achieve superior cost savings, productivity, and scalability. Contact us today to discuss how our tailored furnace solutions can benefit your business!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What industries benefit from Vacuum Induction Melting Furnaces? Unlock High-Purity Metals for Aerospace, Medical, and More

- What are the key components of a Vacuum Induction Melting (VIM) furnace? Master High-Purity Metal Processing

- What are the main applications of vacuum induction melting (VIM) furnaces? Achieve Unmatched Metal Purity for Critical Industries

- What are the main industrial applications of vacuum melting furnaces? Achieve Unmatched Material Purity and Performance

- What components make up a Vacuum Induction Melting Furnace? Discover the Key Systems for Pure Metal Melting