In short, the air vent is essential for safety and equipment longevity. A muffle furnace vent performs the critical function of evacuating harmful gases and vapors produced during the heating process. This protects both the furnace operator from toxic fumes and the internal components, particularly the heating elements, from corrosive damage that would shorten the furnace's lifespan.

The primary purpose of a muffle furnace vent is twofold: it removes hazardous byproducts for operator safety and prevents those same byproducts from degrading the furnace's internal chamber and heating elements, ensuring both safety and long-term reliability.

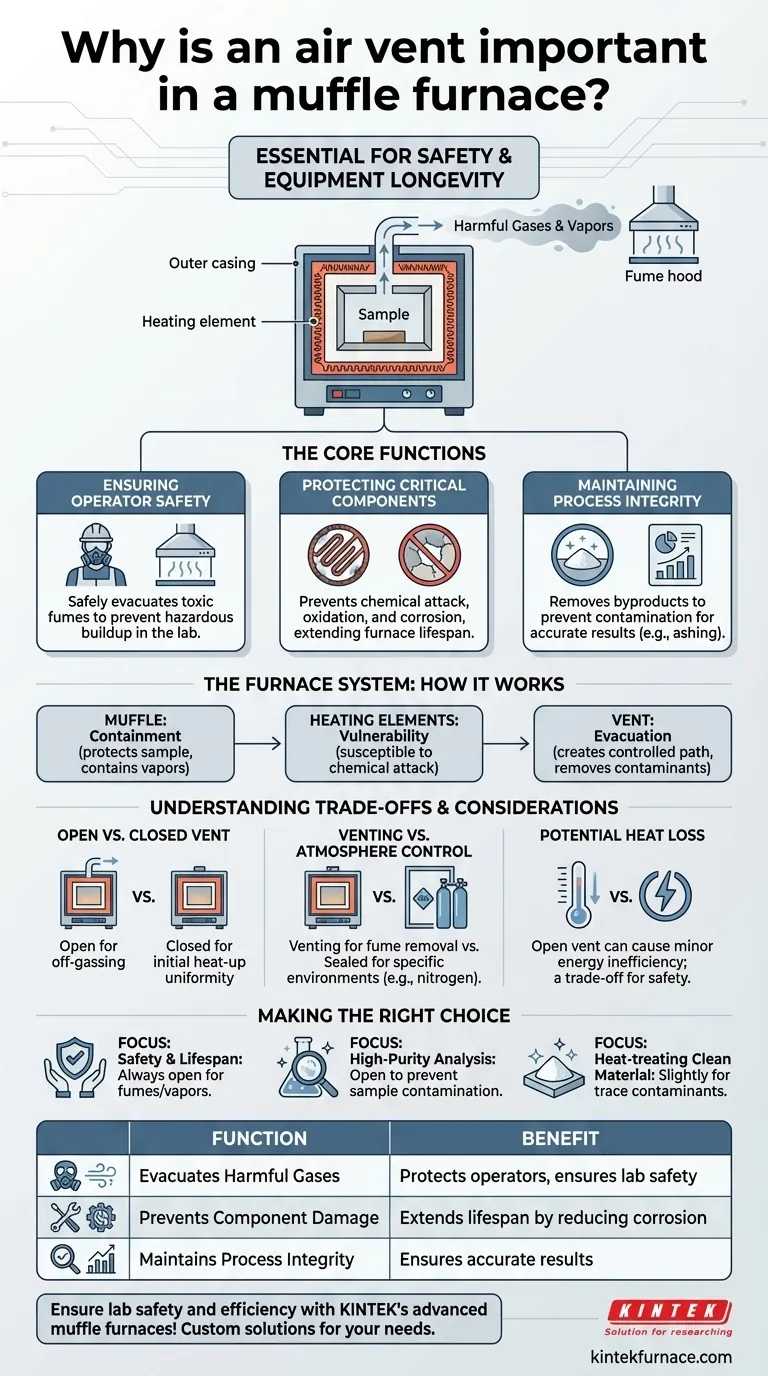

The Core Functions of a Muffle Furnace Vent

While it may seem like a minor component, the air vent or exhaust port plays three distinct and critical roles in the proper operation of a muffle furnace.

Ensuring Operator Safety

Many materials release toxic, corrosive, or noxious fumes when subjected to high temperatures. The vent's most important job is to safely channel these gases out of the chamber and, typically, into an external fume hood or ventilation system. This prevents a hazardous buildup of fumes in the lab environment.

Protecting Critical Furnace Components

The gases released from a sample don't just disappear; they can attack the furnace itself. These vapors can cause the electric heating elements to oxidize, rust, or corrode, leading to premature failure and costly repairs. The refractory lining of the muffle chamber can also be degraded by chemical attack if these byproducts are not properly evacuated.

Maintaining Process Integrity

For applications like ashing or trace element analysis, any contamination can ruin the results. By continuously removing gaseous byproducts, the vent prevents them from redepositing onto or reacting with the sample. This ensures the heated atmosphere inside the chamber remains clean, leading to more accurate and repeatable outcomes.

How the Vent Fits Into the Furnace System

To understand the vent's importance, you must see it as part of a system. The vent works in concert with the furnace's core components.

The Muffle's Role: Containment

A key feature of a muffle furnace is the inner chamber, or "muffle." It provides thermal separation, protecting the sample from direct contact with the heating elements. It also serves to contain the process, including any vapors released from the sample.

The Vent's Role: Evacuation

Once the muffle contains these byproducts, the vent provides the necessary exit path. It creates a controlled leak, allowing fresh air to be drawn in (if needed) and fumes to be pushed out, ensuring a one-way flow of contaminants away from the sample and the heating elements.

The Heating Elements' Vulnerability

Modern muffle furnaces primarily use electric resistance heating. The metallic alloys used for these elements are designed to withstand extreme heat but can be highly vulnerable to chemical attack from sulfur, halogens, and other compounds released during sample burnout. Venting is their primary defense.

Understanding the Trade-offs and Considerations

Proper use of a vent involves understanding a few key trade-offs to optimize your process.

Open vs. Closed Vent Operation

For most applications involving organic material, binders, or plastics, the vent should be open during the heating cycle. However, it may be kept closed during the initial heat-up phase to achieve maximum temperature uniformity before significant off-gassing begins.

Venting vs. Atmosphere Control

A simple vent is for evacuating fumes into the ambient air or an exhaust hood. This is distinct from furnaces designed for controlled atmospheres, which use sealed chambers and gas inlet ports to process materials in a specific environment (e.g., nitrogen or argon).

Potential for Minor Heat Loss

An open vent creates a path for heat to escape. This can lead to slightly lower temperature uniformity near the port and may require the control system to work harder to maintain a setpoint. This minor energy inefficiency is a necessary trade-off for the crucial benefits of safety and equipment protection.

Making the Right Choice for Your Process

Use the vent strategically based on the goal of your heating application.

- If your primary focus is operator safety and furnace lifespan: Always open the vent when heating any material that could release fumes, vapors, or smoke.

- If your primary focus is high-purity analysis (e.g., ashing): Use the vent to prevent airborne byproducts from contaminating your sample and skewing results.

- If your primary focus is heat-treating a clean, inert material: Venting is less critical, but opening it slightly is still good practice to remove any trace moisture or surface contaminants.

Ultimately, viewing the vent as a non-negotiable safety and maintenance feature will ensure your furnace operates reliably for years to come.

Summary Table:

| Function | Benefit |

|---|---|

| Evacuates Harmful Gases | Protects operators from toxic fumes and ensures lab safety |

| Prevents Component Damage | Extends furnace lifespan by reducing corrosion of heating elements |

| Maintains Process Integrity | Ensures accurate results by preventing sample contamination |

| Supports Controlled Atmosphere | Aids in managing heat and fumes for reliable performance |

Ensure your lab's safety and efficiency with KINTEK's advanced muffle furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong customization capabilities precisely meet your unique experimental needs. Contact us today to learn how our products can protect your equipment and enhance your processes!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation