In dental restorations, accuracy and fit are the absolute foundation of clinical success. A porcelain furnace is the critical instrument that enables technicians to achieve the microscopic precision required, transforming raw ceramic materials into a prosthetic that functions comfortably and durably within the patient's mouth for years to come.

A porcelain furnace does not simply heat ceramic; it executes a highly controlled process of sintering and glazing. This precision is what manages material shrinkage and fusion, ensuring the final restoration has the exact dimensions required for a seamless fit, proper bite, and long-term oral health.

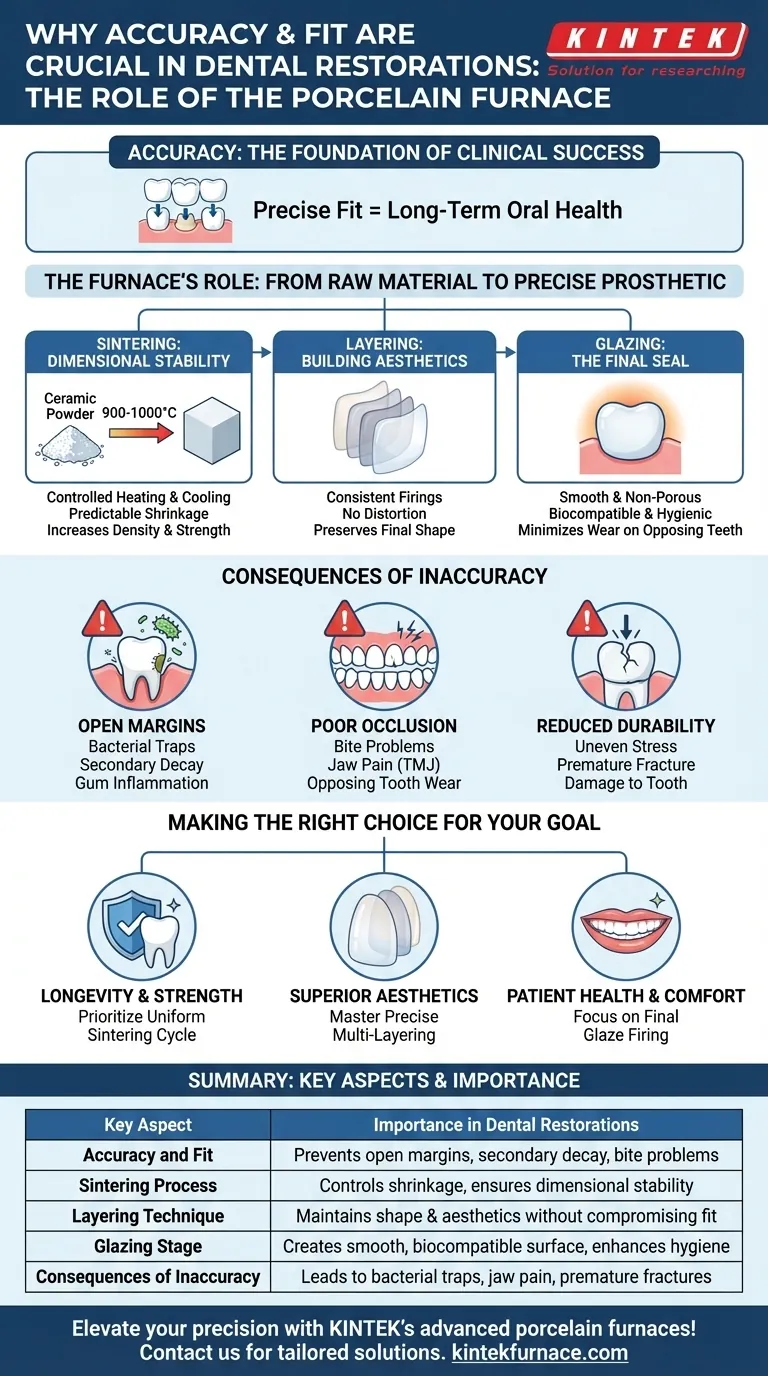

The Furnace's Role: From Raw Material to Precise Prosthetic

The primary function of a porcelain furnace is to transform malleable ceramic powders into a dense, strong, and stable final structure. This transformation is not arbitrary; it is a carefully managed process with distinct stages, each one critical to the final fit and accuracy.

Sintering: The Key to Dimensional Stability

Sintering is the core process. The furnace heats the porcelain particles to a specific temperature range, typically between 900-1000°C, where they fuse together without fully melting.

This fusion dramatically increases the restoration's density and strength. Critically, it also causes the material to shrink. The furnace's ability to automatically and precisely control the temperature cycle ensures this shrinkage is predictable and uniform, resulting in the exact final dimensions specified by the design.

Layering: Building Aesthetics with Precision

For highly aesthetic restorations like crowns and veneers, technicians build up color and translucency in multiple layers. Each layer of porcelain must be fired separately.

A precision furnace allows for consistent results with each firing. This ensures that the cumulative effect of layering does not warp the restoration or compromise the accuracy of the final fit against the prepared tooth.

Glazing: The Final Seal for Health and Function

The final firing stage is glazing. This creates a very smooth, non-porous, and stain-resistant surface on the restoration.

From a functional standpoint, this smooth surface is biocompatible, easy for the patient to keep clean, and minimizes wear on the opposing natural teeth. A properly glazed surface ensures the restoration integrates harmoniously into the oral environment.

The Clinical Consequences of Inaccuracy

When a restoration lacks an accurate fit, the consequences extend far beyond minor discomfort. These failures undermine the very purpose of the treatment and can cause significant long-term problems.

Compromised Fit and Open Margins

An inaccurate fit results in gaps between the restoration and the tooth, known as open margins. These gaps become traps for bacteria and plaque, dramatically increasing the risk of secondary tooth decay under the restoration and leading to gum inflammation.

Poor Occlusion and Bite Problems

If a crown or bridge is not dimensionally accurate, it will interfere with the patient's bite (occlusion). This can cause chewing difficulties, jaw pain (TMJ issues), and excessive wear or even fracture of the opposing teeth.

Reduced Durability and Fracture Risk

A restoration that does not fit perfectly will experience uneven stress concentration when the patient chews. These high-stress points can lead to the premature fracture of the ceramic material or even damage to the underlying tooth structure.

Making the Right Choice for Your Goal

The successful use of a porcelain furnace requires understanding how each step contributes to the final clinical outcome. Your focus during the fabrication process will determine the quality of the result.

- If your primary focus is longevity and strength: Prioritize a complete and uniform sintering cycle, strictly following the ceramic manufacturer's heating and cooling parameters.

- If your primary focus is superior aesthetics: Master the art of multi-layering, ensuring each firing is precise to control shade and translucency without distorting the restoration's shape.

- If your primary focus is patient health and comfort: Pay meticulous attention to the final glaze firing to create a perfectly smooth, non-porous surface that ensures hygiene and a harmonious bite.

Ultimately, mastery of the porcelain furnace is what elevates a dental restoration from a simple replacement to a seamless and lasting part of the patient's anatomy.

Summary Table:

| Key Aspect | Importance in Dental Restorations |

|---|---|

| Accuracy and Fit | Prevents open margins, secondary decay, and bite problems for clinical success |

| Sintering Process | Controls shrinkage and ensures dimensional stability for durable restorations |

| Layering Technique | Maintains shape and aesthetics without compromising fit during multiple firings |

| Glazing Stage | Creates a smooth, biocompatible surface that enhances hygiene and reduces wear |

| Consequences of Inaccuracy | Leads to bacterial traps, jaw pain, and premature fractures, undermining treatment |

Elevate your dental lab's precision and outcomes with KINTEK's advanced porcelain furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures these tools meet your unique requirements for sintering, layering, and glazing, delivering restorations with superior accuracy, fit, and durability. Don't let inaccuracy compromise patient care—contact us today to discuss how our tailored furnace solutions can enhance your workflow and results!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique