At its core, vacuum annealing is widely used because it removes atmospheric gases that react harmfully with metals at high temperatures. By creating a controlled, inert environment, these furnaces prevent oxidation and other unwanted chemical changes, resulting in a cleaner surface finish, superior mechanical properties, and highly repeatable outcomes that are critical for modern manufacturing in sectors like aerospace, automotive, and electronics.

The primary value of a vacuum furnace is not just about heating metal; it's about fundamentally changing the processing environment. By removing reactive gases, you gain absolute control over the material's final properties, shifting from a process of approximation to one of precision engineering.

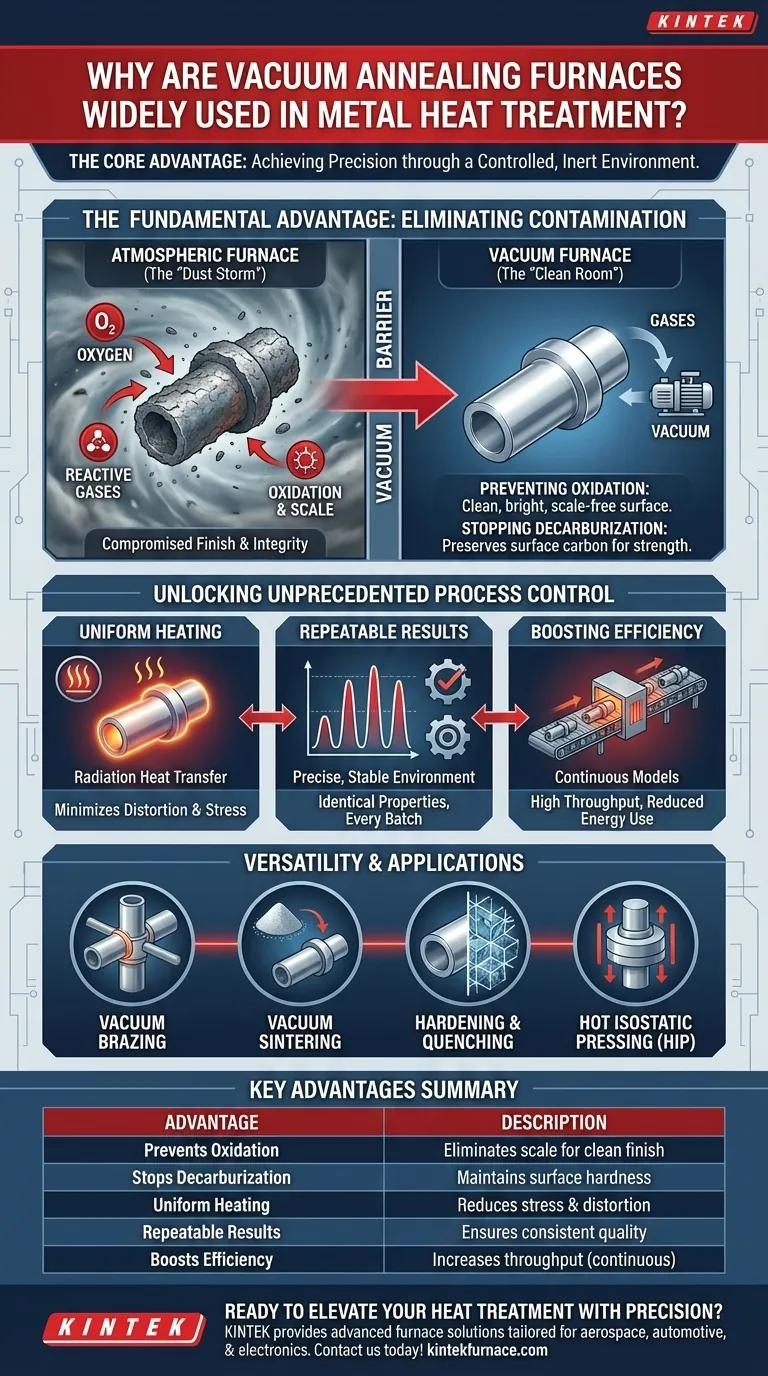

The Fundamental Advantage: Eliminating Contamination

Heating metal in the open air is like trying to paint in a dust storm—unwanted particles will inevitably ruin the final product. A vacuum furnace solves this by removing the "dust," which in this case are reactive gases like oxygen.

Preventing Oxidation for a Pristine Finish

When heated, most metals readily react with oxygen in the air, forming a layer of oxide scale on the surface. This process, oxidation, compromises the part's dimensions, finish, and material integrity.

A vacuum furnace evacuates nearly all the air, preventing this reaction from ever occurring. The result is a bright, clean, and scale-free surface that often requires no subsequent cleaning or finishing.

Stopping Decarburization to Preserve Strength

For carbon steels, another risk is decarburization, where carbon atoms on the metal's surface react with the atmosphere and are lost. This softens the surface layer, reducing the material's wear resistance and fatigue strength.

The inert environment inside a vacuum furnace protects the material's chemical composition, ensuring its mechanical properties, such as hardness and strength, remain exactly as designed.

Unlocking Unprecedented Process Control

Beyond preventing contamination, a vacuum environment enables a level of control that is impossible to achieve with traditional atmospheric furnaces.

Achieving Uniform Heating

Without air to create convection currents, heat transfer in a vacuum is primarily through radiation. This allows for extremely uniform heating, ensuring the entire workpiece, regardless of its complexity, reaches the target temperature at the same rate.

This uniformity minimizes internal stresses and distortion, which is critical for components with tight geometric tolerances.

Ensuring Repeatable Results

A vacuum is a highly stable and precisely measurable environment. This allows engineers to program and execute heating and cooling cycles with exceptional accuracy and repeatability.

Every batch processed under the same vacuum level and temperature profile will exhibit virtually identical metallurgical properties, ensuring consistent quality for large-scale production.

Boosting Production Efficiency

Modern continuous vacuum furnaces operate without interruption, moving parts through heating and cooling zones in an ongoing process. This eliminates the downtime and energy waste associated with heating and cooling traditional batch furnaces between loads.

The result is significantly higher throughput, reduced energy consumption per part, and optimized manufacturing workflows.

Understanding the Trade-offs and Versatility

While powerful, vacuum technology is not a universal solution. Understanding its context is key to leveraging it effectively.

Batch vs. Continuous Furnaces

Batch furnaces are ideal for smaller production runs, highly specialized components, or processes requiring long, complex cycles. They offer flexibility but are less efficient for high-volume manufacturing.

Continuous furnaces, as noted, are designed for high-volume, standardized production where maximizing throughput and energy efficiency is the primary goal.

Not Just for Annealing

The controlled environment of a vacuum furnace makes it incredibly versatile. The same fundamental principles are applied to other critical thermal processes, including:

- Vacuum Brazing: Joining complex assemblies with a filler metal, creating strong, clean joints without flux.

- Vacuum Sintering: Fusing metal powders to create solid, dense parts in powder metallurgy.

- Hardening & Quenching: Achieving specific hardness properties with precise and rapid cooling.

- Hot Isostatic Pressing (HIP): Applying high pressure and temperature to eliminate internal voids and achieve maximum material density.

Making the Right Choice for Your Goal

The decision to use a vacuum furnace, and which type, depends entirely on the material, the process, and the production objective.

- If your primary focus is large-scale, efficient production: A continuous vacuum furnace provides the best throughput and energy economy.

- If your primary focus is high-precision joining of complex parts: A specialized vacuum brazing furnace is the correct tool.

- If your primary focus is creating dense parts from metal powders: A vacuum sintering furnace is designed specifically for this application.

- If your primary focus is achieving maximum material performance and eliminating defects: A Hot Isostatic Pressing (HIP) unit offers unparalleled density and strength.

Ultimately, adopting vacuum heat treatment is about gaining mastery over your material by controlling its environment with absolute precision.

Summary Table:

| Key Advantage | Description |

|---|---|

| Prevents Oxidation | Eliminates surface scale for a clean, bright finish without post-treatment. |

| Stops Decarburization | Maintains carbon content to preserve hardness and strength in steels. |

| Uniform Heating | Uses radiation for even temperature distribution, reducing stress and distortion. |

| Repeatable Results | Ensures consistent metallurgical properties across batches for reliable quality. |

| Boosts Efficiency | Continuous models increase throughput and reduce energy use in high-volume production. |

Ready to elevate your metal heat treatment with precision and efficiency? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for industries like aerospace, automotive, and electronics. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to meet your unique experimental needs. Contact us today to discuss how our vacuum furnaces can deliver cleaner finishes, superior mechanical properties, and repeatable outcomes for your operations!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance