In modern manufacturing, an inert atmosphere furnace is essential because it creates a chemically non-reactive environment for high-temperature processing. This controlled atmosphere prevents unwanted reactions, primarily oxidation and contamination, which is critical for ensuring the integrity, performance, and quality of advanced materials in industries from metallurgy to semiconductors.

The true value of an inert atmosphere furnace is not just its ability to heat materials, but its power to control the chemical environment during that heating. This control makes it possible to achieve specific material properties that are simply unattainable in open air.

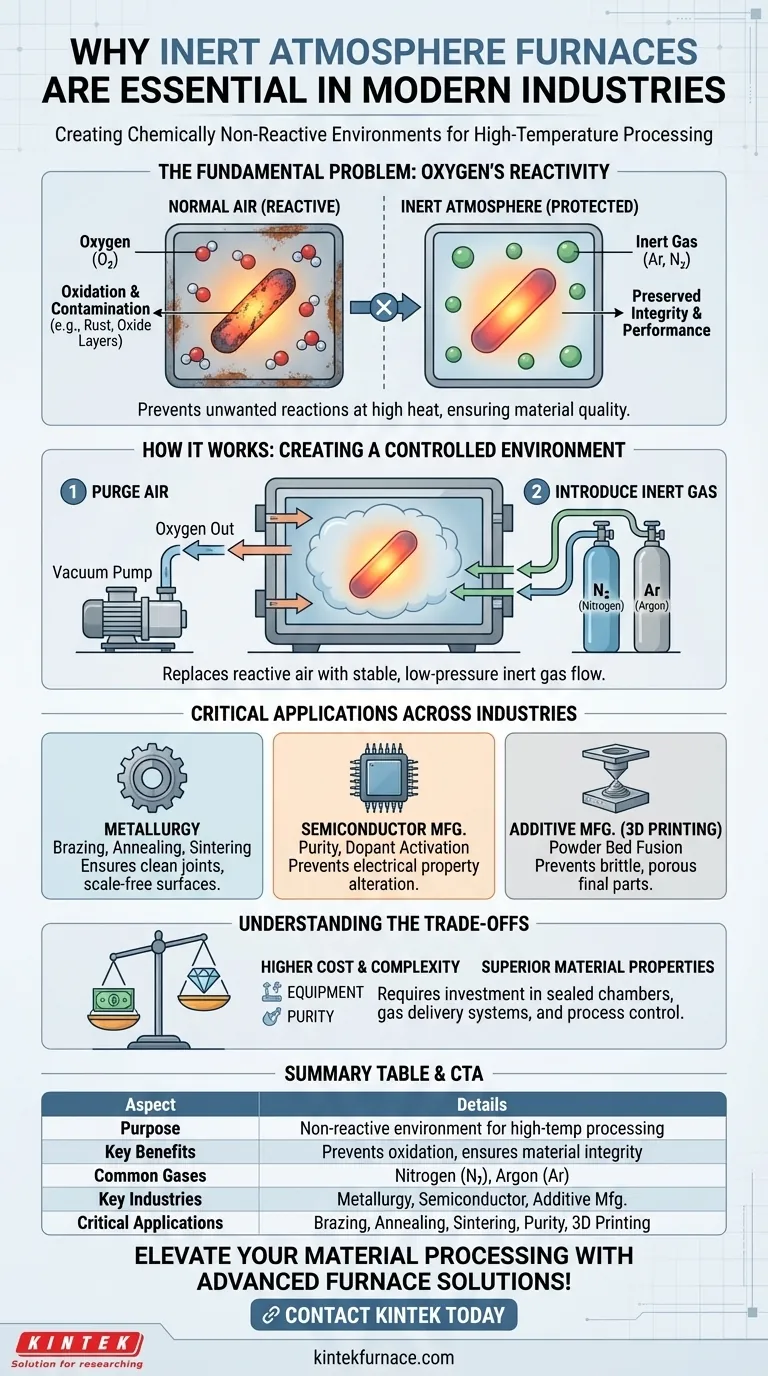

The Fundamental Problem: Oxygen's Reactivity

Why Normal Air Is a Problem

At room temperature, the oxygen in the air is relatively benign. However, at the high temperatures required for processes like brazing, annealing, or sintering, oxygen becomes extremely reactive.

This reactivity causes oxidation—the same chemical process that causes iron to rust. When processing sensitive metals or materials, this leads to the formation of unwanted oxide layers on the material's surface.

The Impact of Oxidation and Contamination

Oxidation and other forms of contamination are not minor issues; they fundamentally degrade the material.

These unwanted reactions can dramatically reduce a material's structural integrity, create weak points in bonded joints, alter a semiconductor's electrical properties, or lead to outright component failure. For high-performance applications, even microscopic levels of contamination can be catastrophic.

How Inert Atmosphere Furnaces Provide the Solution

Creating a Controlled Environment

An inert atmosphere furnace solves this problem by systematically removing the reactive atmosphere (air) and replacing it with a non-reactive one.

This is typically achieved by first purging the sealed furnace chamber to remove the oxygen. Then, a continuous, low-pressure flow of an inert gas is introduced to maintain a clean, oxygen-free environment throughout the heating and cooling cycle.

The Role of Inert Gases

The most commonly used inert gases are Nitrogen (N₂) and Argon (Ar).

These gases are chosen because they are chemically stable and will not react with the materials being processed, even at extreme temperatures. This ensures that the only changes happening to the material are the ones intended by the heat treatment process itself.

Critical Applications Across Industries

Metallurgy: Brazing, Annealing, and Sintering

In metallurgy, inert atmospheres are crucial for joining, shaping, and strengthening metals. During brazing, an inert gas prevents oxides from forming, which would otherwise inhibit the flow of the filler metal and create a weak joint.

For annealing, the process of heating and cooling to soften a metal and relieve internal stress, an inert atmosphere ensures a clean, bright surface finish free of scale.

Semiconductor Manufacturing: Purity and Precision

The semiconductor industry relies on absolute purity. Processes like dopant activation or the annealing of thin films must occur in an oxygen-free environment.

Even trace amounts of oxygen can contaminate the silicon wafer, altering its electrical properties and rendering the resulting microchips useless. An inert atmosphere is the only way to guarantee the required purity and reliability.

Additive Manufacturing: Powder Bed Fusion

In metal 3D printing, such as powder bed fusion, fine metal powders are melted layer-by-layer with a laser or electron beam.

These powders have an enormous surface-area-to-volume ratio, making them incredibly susceptible to oxidation. Processing them in an inert atmosphere is essential to prevent the formation of oxides that would result in a brittle, porous, and structurally compromised final part.

Understanding the Trade-offs

Cost and Complexity

Inert atmosphere systems are inherently more complex and expensive than standard air furnaces. They require tightly sealed chambers, sophisticated gas delivery and monitoring systems, and vacuum pumps, all of which increase initial investment.

Operational Costs

Beyond the initial purchase, there is an ongoing operational cost associated with the consumption of inert gases. The sourcing, storage, and handling of high-purity gas cylinders or bulk tanks must be factored into the total cost of ownership.

Process Control Requirements

Operating an inert atmosphere furnace demands more rigorous process control. Operators must be trained to manage gas flow rates, monitor for leaks, and ensure the atmospheric purity remains within strict specifications for the entire process cycle to be successful.

Making the Right Choice for Your Process

Choosing the right furnace technology depends entirely on the chemical nature of your material and your final quality requirements.

- If your primary focus is material integrity and strength: An inert atmosphere is non-negotiable for heat-treating reactive metals, brazing critical joints, or sintering powdered metals.

- If your primary focus is electronic or chemical purity: For applications in semiconductors, medical implants, or aerospace, an inert environment is the only way to prevent performance-killing contamination.

- If your primary focus is cost-sensitive, non-reactive materials: For simple heat-treating of materials that do not readily oxidize, a standard air furnace is often a more economical and perfectly sufficient choice.

Ultimately, mastering your material requires you to first master its environment.

Summary Table:

| Aspect | Details |

|---|---|

| Purpose | Creates a non-reactive environment for high-temperature processing |

| Key Benefits | Prevents oxidation and contamination, ensures material integrity and performance |

| Common Gases | Nitrogen (N₂), Argon (Ar) |

| Key Industries | Metallurgy, Semiconductor Manufacturing, Additive Manufacturing |

| Critical Applications | Brazing, Annealing, Sintering, Dopant Activation, Powder Bed Fusion |

| Trade-offs | Higher initial cost, operational gas expenses, need for rigorous process control |

Elevate your material processing with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, whether in metallurgy, semiconductors, or additive manufacturing. Contact us today to discuss how we can enhance your process efficiency and material quality!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality

- How does a batch type controlled atmosphere furnace operate? Master Precision Heat Treatment for Superior Materials

- What industries commonly use inert atmosphere heat treating? Key Applications in Military, Automotive, and More

- What are the key advantages of an experimental box type atmosphere furnace? Achieve Precise Environmental Control for Advanced Materials

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment