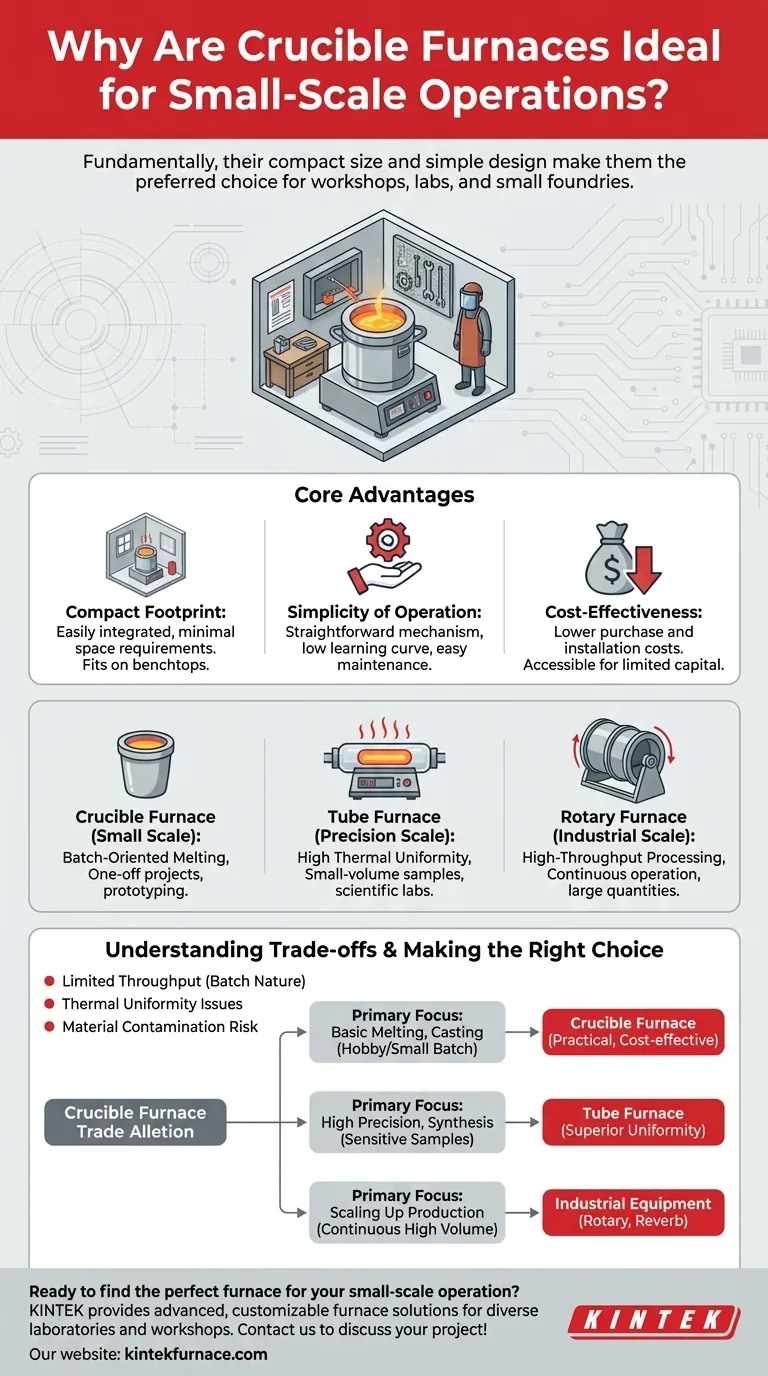

Fundamentally, crucible furnaces are ideal for small-scale operations because of their compact size and simple design. Their small footprint allows them to be easily integrated into workshops, laboratories, and small foundries where space is a significant constraint, eliminating the need for major facility modifications.

While a crucible furnace's simplicity and small size make it the default choice for basic, small-batch melting, the "ideal" furnace truly depends on your specific goals. The right choice involves balancing capacity, operational simplicity, and the need for thermal precision.

The Core Advantages for Small-Scale Operations

The primary benefits of a crucible furnace directly address the common constraints faced by smaller workshops, labs, and hobbyists.

Compact Footprint

Crucible furnaces are valued for their minimal space requirements. Unlike large industrial furnaces that demand dedicated rooms and infrastructure, a small crucible furnace can often fit on a benchtop or in a corner of a workshop.

This makes them exceptionally easy to install and integrate into existing setups without significant disruption or cost.

Simplicity of Operation

At its core, a crucible furnace is a container (the crucible) placed inside an insulated chamber that gets heated. This straightforward mechanism makes them relatively easy to operate, maintain, and troubleshoot.

For small teams or single operators, this simplicity reduces the learning curve and lowers the risk of operational error.

Cost-Effectiveness

The smaller size and simpler construction of crucible furnaces make them significantly less expensive to purchase and install than their larger, more complex counterparts.

For businesses or research groups with limited capital, this lower entry cost makes material melting and processing accessible.

How Furnace Type Relates to Operational Scale

Understanding why a crucible furnace fits the "small-scale" label requires comparing it to other furnace types designed for different throughputs and applications.

The Crucible Furnace: Batch-Oriented Melting

A crucible furnace is inherently a batch processing tool. You load a specific quantity of material, melt it, and pour it. This is perfectly suited for one-off projects, small production runs, or experimental melts.

Its capacity is defined by the size of the crucible, which is inherently limited.

The Tube Furnace: Precision for Low-Volume Samples

At a similar small scale, tube furnaces serve a different purpose. They excel at providing unmatched thermal uniformity for processing small-volume samples.

While also low-throughput, their strength is precision thermal treatment, not bulk melting, making them a staple in scientific laboratories for sensitive applications.

The Rotary Furnace: High-Throughput Industrial Processing

On the opposite end of the spectrum, rotary furnaces are built for high production capacity. Their design allows for the continuous processing of large quantities of material.

They represent true industrial-scale operation, highlighting by contrast why a crucible furnace's batch nature makes it unsuited for high-volume manufacturing.

Understanding the Trade-offs

The simplicity that makes crucible furnaces ideal for small operations also introduces limitations that are critical to understand.

Limited Throughput

The batch-based nature means production is not continuous. The time it takes to heat, melt, pour, and reset for the next batch creates a natural ceiling on how much material can be processed in a day.

Thermal Uniformity

While effective for melting, a simple crucible furnace may not provide the same level of precise, uniform temperature control throughout the material as a more specialized furnace, like a tube furnace. The heat source is external, meaning the material at the edge of the crucible will be hotter than the material in the center.

Material Contamination Risk

The molten metal is in direct contact with the crucible material. Over time, the crucible can degrade and introduce impurities into the melt, which may be unacceptable for certain high-purity alloys or applications.

Making the Right Choice for Your Goal

Selecting the correct furnace is about aligning the equipment's capabilities with your primary objective.

- If your primary focus is basic melting of non-ferrous metals for casting, hobby work, or small-batch prototyping: A crucible furnace is almost certainly the most practical and cost-effective choice.

- If your primary focus is high-precision heat treatment or synthesis of small, sensitive material samples: A tube furnace is the superior tool due to its exceptional thermal uniformity.

- If your primary focus is scaling up production to a continuous, high-volume operation: You must look beyond these options toward industrial equipment like rotary or reverb furnaces.

By understanding this balance of scale and precision, you can select the furnace that will serve as a true asset to your operation.

Summary Table:

| Feature | Benefit for Small-Scale Operations |

|---|---|

| Compact Footprint | Easy integration into workshops/labs; no major facility changes needed. |

| Simple Operation | Low learning curve; easy to maintain and troubleshoot. |

| Cost-Effectiveness | Lower purchase and installation cost vs. industrial furnaces. |

| Batch Processing | Ideal for one-off projects, prototyping, and small production runs. |

Ready to find the perfect furnace for your small-scale operation?

At KINTEK, we understand the unique challenges of small-batch melting and precision heat treatment. Leveraging our exceptional R&D and in-house manufacturing, we provide diverse laboratories and workshops with advanced furnace solutions.

Our product line, including Muffle, Tube, and Crucible Furnaces, is complemented by our strong deep customization capability to precisely meet your unique experimental requirements. Whether you need a standard crucible furnace or a custom solution, we are here to help you maximize efficiency.

Contact us today to discuss your project and discover the ideal furnace for your needs!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Induction Melting Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- How do you prevent maintenance on a muffle furnace? Extend Lifespan with Proactive Care

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals