In short, muffle furnaces are a cornerstone of any industry requiring high-temperature processing in a controlled, contamination-free environment. Their use spans from advanced materials science and manufacturing to analytical chemistry and quality control. Key sectors include ceramics, metallurgy, pharmaceuticals, and environmental testing, where they are used for everything from creating finished goods to analyzing material composition.

The specific industry is less important than the underlying need. Muffle furnaces are chosen whenever a material must be heated to a high temperature without being contaminated by fuel, combustion byproducts, or the heating elements themselves.

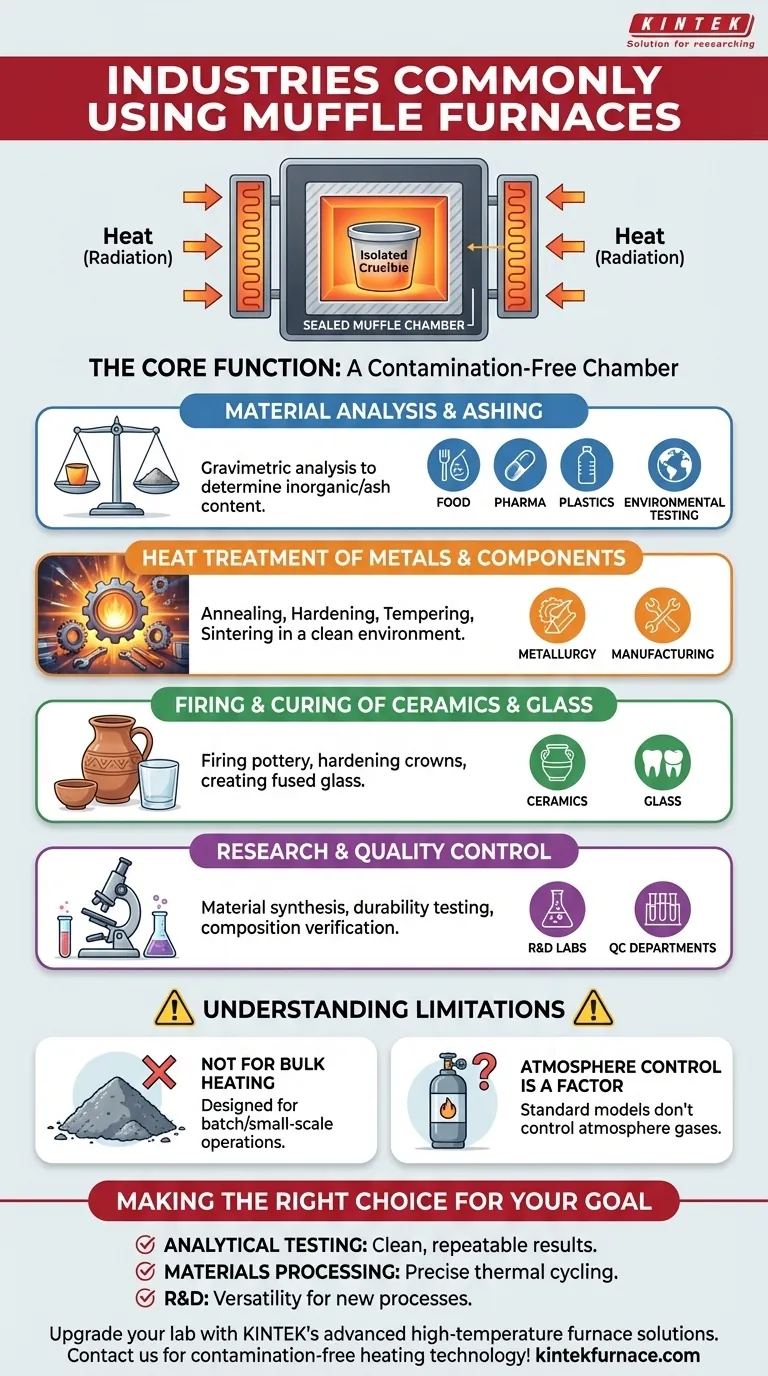

The Core Function: A Contamination-Free Chamber

To understand where muffle furnaces are used, you must first understand their defining purpose: to isolate the heated material.

What "Muffle" Means

The term "muffle" refers to the inner chamber that contains the sample. This chamber is sealed off from the heating elements and any combustion byproducts.

This design ensures that the heat is transferred indirectly (typically through radiation), providing a very clean environment. This is the furnace's primary advantage over direct-fired ovens.

Why Isolation is Critical

In many processes, direct exposure to flame or electric elements can introduce impurities that alter the chemical or physical properties of the material being tested or created.

The muffle design prevents this, making it essential for applications where sample purity and process integrity are paramount.

Key Applications Across Industries

The need for a clean, high-temperature environment dictates the use of a muffle furnace. This need appears in several key applications that cross many industrial sectors.

Material Analysis and Ashing

This is one of the most common applications. The furnace is used to burn off all organic matter from a sample, leaving only the non-combustible ash for measurement. This is known as gravimetric analysis.

Industries like food, pharmaceuticals, plastics, coal, and environmental testing rely on this to determine the filler or inorganic content of their products.

Heat Treatment of Metals and Components

In metallurgy and manufacturing, muffle furnaces are used for processes that modify the properties of metals without melting them.

Processes like annealing (softening), hardening (strengthening), tempering (reducing brittleness), and sintering (fusing powdered material) all require precise temperature control in a clean environment to avoid oxidation or contamination.

Firing and Curing of Ceramics and Glass

The ceramics and glass industries use muffle furnaces extensively. They are essential for firing pottery, hardening dental crowns, and creating fused glass components.

The controlled, even heating ensures the material cures properly without imperfections, while the isolated chamber prevents discoloration from combustion gases.

Research and Quality Control

In R&D labs and quality control departments, muffle furnaces are a versatile tool. Researchers use them for material synthesis, while QC technicians use them to test material properties.

This includes simulating extreme heat conditions to assess component durability, verifying the composition of raw materials, or preparing samples for further chemical analysis.

Understanding the Limitations

While versatile, a muffle furnace is not the solution for every high-temperature task. Understanding its limitations is key to using it effectively.

Not for Bulk Industrial Heating

Muffle furnaces are typically designed for batch processes or smaller-scale operations. They are not efficient for heating massive volumes of material where contamination is not a concern.

For large-scale melting or smelting, direct-fired or induction furnaces are often more practical and economical.

Atmosphere Control is a Factor

A standard muffle furnace provides a clean-air environment but does not control the atmosphere itself.

If a process requires a specific inert gas (like argon) or a reactive gas, a specialized atmosphere furnace is necessary. The muffle design is primarily about preventing contamination from the heat source, not managing the ambient gases around the sample.

Making the Right Choice for Your Goal

The decision to use a muffle furnace should be driven by the technical requirements of your process.

- If your primary focus is analytical testing: You need a muffle furnace for its ability to produce clean, repeatable results for ash content or compositional analysis.

- If your primary focus is materials processing: You need a muffle furnace for its precise thermal cycling to anneal, sinter, or fire products without introducing impurities.

- If your primary focus is research and development: You need a muffle furnace for its versatility in exploring new thermal processes on a controlled, small-scale basis.

Ultimately, a muffle furnace is the tool of choice whenever your material's integrity cannot be compromised by the heating process itself.

Summary Table:

| Industry/Application | Key Uses |

|---|---|

| Ceramics & Glass | Firing, curing, hardening dental crowns |

| Metallurgy | Annealing, hardening, tempering, sintering |

| Pharmaceuticals | Material analysis, ashing for purity |

| Environmental Testing | Gravimetric analysis, ash content measurement |

| Food & Plastics | Determining inorganic content |

| R&D & Quality Control | Material synthesis, durability testing |

Upgrade your lab's capabilities with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable muffle, tube, rotary, vacuum, atmosphere furnaces, and CVD/PECVD systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs in ceramics, metallurgy, pharmaceuticals, and more. Contact us today to discuss how our contamination-free heating technology can enhance your processes and results!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure