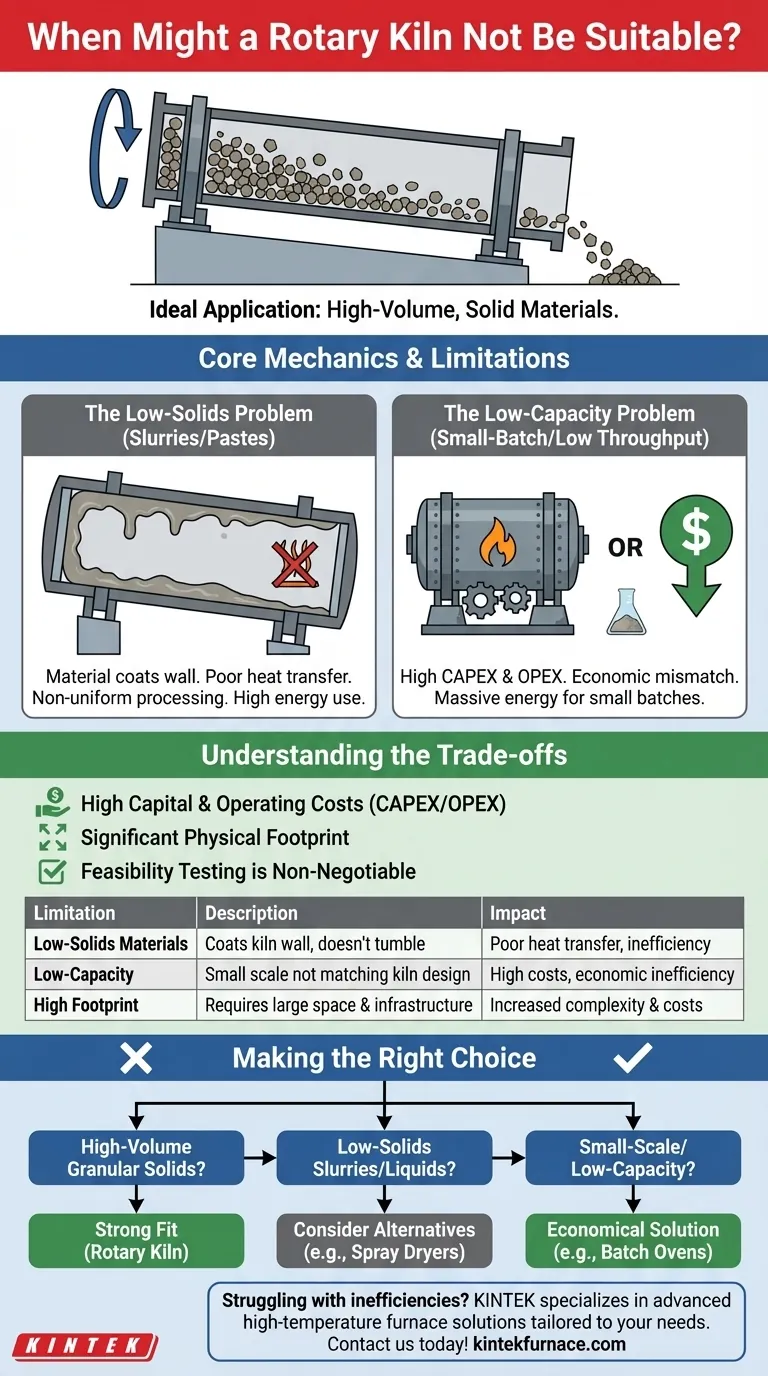

In short, a rotary kiln is generally unsuitable for applications involving low-solids materials or those with low-capacity requirements. Its design is optimized for high-volume processing of solids, and using it outside of this specific context leads to significant operational and economic inefficiencies.

A rotary kiln's effectiveness is rooted in its ability to tumble and process large volumes of solid material. When an application lacks either sufficient solids content or the necessary scale, the fundamental mechanics and economics of the kiln break down, making alternative technologies a more practical choice.

The Core Mechanics of a Rotary Kiln

To understand a rotary kiln's limitations, we must first understand its fundamental operating principle. It is, at its core, a simple and robust machine designed for a specific purpose.

How a Kiln Works: Tumbling and Residence Time

A rotary kiln is a large, rotating cylinder set at a slight incline. Material is fed into the higher end and moves toward the lower end due to the rotation and gravity.

This tumbling action, known as cascading, is critical. It constantly exposes new surfaces of the material to the hot gas stream and the heated kiln shell, ensuring uniform heat transfer.

The Importance of Material Flow

The efficiency of the entire process depends on this consistent, predictable flow and tumbling of solid particles. The kiln's size, rotation speed, and angle are all calibrated to achieve a specific residence time for a particular type of solid material.

Unpacking the Key Limitations

The kiln's reliance on tumbling solids creates clear boundaries for its use. When these conditions aren't met, the system's efficiency plummets.

The "Low-Solids" Problem: Coating and Inefficiency

Materials with low solids content, such as slurries or wet pastes, do not tumble. Instead, they tend to coat the interior wall of the kiln.

This coating action is highly problematic. It insulates the material from the heated kiln shell, severely impeding heat transfer. It also prevents the cascading effect, meaning the material is not properly mixed or exposed to the process atmosphere.

Ultimately, this leads to non-uniform processing, increased energy consumption, and potential operational issues from buildup.

The "Low-Capacity" Problem: Economic Mismatch

Rotary kilns are heavy industrial equipment with significant capital and operational costs. Their large motors, refractory linings, and massive support structures represent a major investment.

For low-throughput or small-batch applications, this cost is simply not justifiable. The energy required to heat the large thermal mass of the kiln and keep it at temperature is immense, making it deeply uneconomical for processing small quantities of material.

It is the equivalent of using a freight train to deliver a single package—the tool is mismatched to the scale of the task.

Understanding the Trade-offs

Choosing a rotary kiln involves accepting a specific set of operational realities. Ignoring them can lead to costly and inefficient projects.

Capital and Operating Costs

The initial purchase price (CAPEX) of a rotary kiln system is high. Furthermore, the energy consumption (OPEX) required to heat and rotate the massive drum is a primary cost driver. This technology is only cost-effective when operated at or near its designed capacity.

Physical Footprint and Infrastructure

These are not small machines. A rotary kiln requires a significant physical footprint and a robust, specially engineered concrete foundation to support its immense weight and dynamic loads. This adds to the overall project cost and complexity.

Feasibility Testing is Non-Negotiable

Because material characteristics have such a profound impact on performance, process testing is essential. A test in a pilot-scale facility is the only definitive way to confirm if a material will flow and process as expected before committing to a large capital investment.

Making the Right Choice for Your Process

Your material properties and production scale are the two most important factors in this decision. Always select the technology that aligns with the core requirements of your specific application.

- If your primary focus is high-volume processing of granular solids: A rotary kiln is a powerful, reliable, and well-understood technology that is likely a strong fit.

- If your primary focus is processing low-solids slurries or liquids: Consider technologies designed for liquids, such as spray dryers or paddle dryers, which offer far greater efficiency.

- If your primary focus is small-scale or low-capacity production: Batch ovens, fluid bed dryers, or other smaller-scale systems will provide a much more economical and practical solution.

Ultimately, matching the processing technology to the material's properties and the project's economic scale is the most critical decision you will make.

Summary Table:

| Limitation | Description | Impact |

|---|---|---|

| Low-Solids Materials | Materials like slurries or pastes that coat the kiln wall instead of tumbling. | Poor heat transfer, non-uniform processing, higher energy use. |

| Low-Capacity Requirements | Small-scale or low-throughput applications not matching the kiln's design scale. | High capital and operational costs, economic inefficiency. |

| High Footprint Needs | Requires large space and robust infrastructure for support. | Increased project complexity and costs. |

Struggling with material processing inefficiencies? KINTEK specializes in advanced high-temperature furnace solutions tailored to your unique needs. Leveraging our exceptional R&D and in-house manufacturing, we offer products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, with strong deep customization capabilities to precisely meet your experimental requirements. Whether you're dealing with low-solids issues or need scalable alternatives, our experts can help optimize your process. Contact us today to discuss how we can enhance your lab's performance and reduce costs!

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why are indirect rotary kilns recommended for lithium processing? Unlock Higher Purity and Recovery Rates

- What makes electric heating advantageous in a rotary kiln electric furnace? Boost Precision and Efficiency

- How does automated control in electric rotary kilns benefit industrial processes? Achieve Unmatched Precision & Efficiency

- How does electromagnetic induction heating work in rotary kilns? Achieve Superior Efficiency and Control

- What are the advantages of gas kilns? Unlock Unique Glaze Effects and Faster Firing

- How are rotary kilns heated? A Guide to Direct vs. Indirect Heating Methods

- What industries commonly use temperature controllable electric heating rotary furnaces? Essential for High-Purity Material Processing

- What industries commonly use electromagnetic rotary kilns? Boost Efficiency in Metallurgy, Drying & More