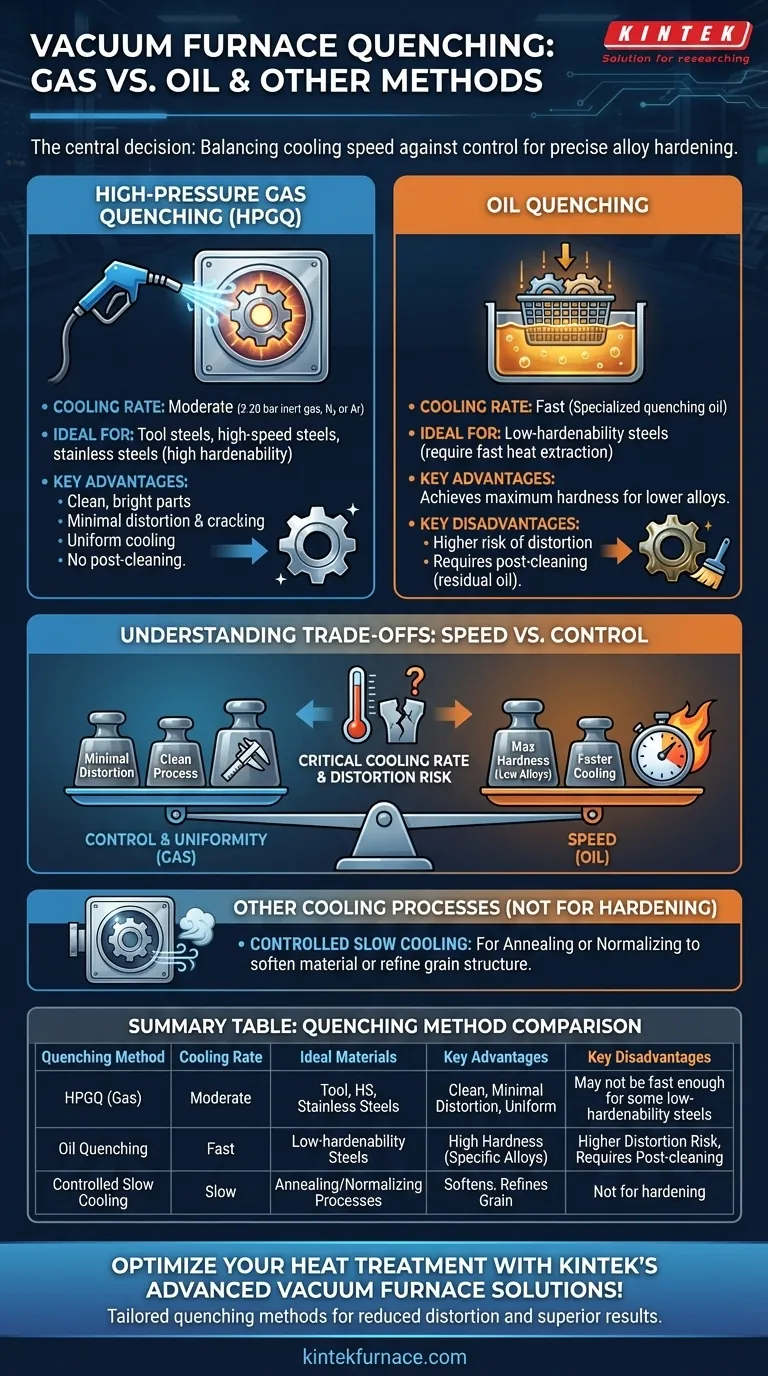

In a vacuum furnace, the primary methods for achieving a full quench are oil quenching and high-pressure gas quenching (HPGQ). While other specialized cooling methods exist, these two represent the core options for hardening metal components after vacuum heat treatment, each offering distinct advantages based on the material and desired final properties.

The central decision in vacuum furnace quenching is not about which method is universally "better," but which one provides the precise cooling rate your specific alloy requires to achieve hardness without introducing unacceptable distortion or cracking.

A Closer Look at Quenching Methods

The method chosen is dictated by the material's hardenability—its inherent ability to form a hard martensitic structure upon cooling.

High-Pressure Gas Quenching (HPGQ)

Gas quenching involves flooding the hot zone with a high-pressure, high-flow-rate stream of inert gas, typically nitrogen or argon. Modern furnaces can achieve pressures from 2 to 20 bar or more to rapidly extract heat.

This method provides exceptional control and uniformity. Because the cooling is less severe than a liquid quench, it is the preferred choice for materials with high hardenability, such as tool steels, high-speed steels, and certain stainless steels.

The result is a clean, bright part with minimal risk of thermal shock, distortion, or cracking, eliminating the need for post-quench cleaning.

Oil Quenching

Oil quenching is a more aggressive method. In this process, the heated workpiece is mechanically transferred from the vacuum chamber into an integrated, sealed tank of specialized quenching oil.

This rapid cooling is necessary for steels with lower hardenability, which require a faster heat extraction rate to achieve full hardness.

While effective, the severity of an oil quench increases the risk of part distortion. It also necessitates a post-treatment cleaning process to remove residual oil.

Other Cooling Processes

While not always considered true "quenching" for hardening, vacuum furnaces also support slower cooling rates for other thermal processes.

Controlled slow cooling can be achieved by simply turning off the heat and letting the part cool in a vacuum or by introducing a low-flow stream of inert gas. This is used for processes like annealing or normalizing, which aim to soften the material or refine its grain structure, not harden it.

Understanding the Trade-offs: Speed vs. Control

Choosing between gas and oil is a critical engineering decision that balances cooling speed against process control.

The Critical Cooling Rate

Every alloy has a critical cooling rate—the minimum speed at which it must be cooled to transform its microstructure into hard martensite. If the cooling is too slow, the material will form softer structures instead.

Materials like high-speed steel have a very low critical cooling rate, making them ideal for the gentler, more controlled gas quench. Other alloys require the much faster rate that only an oil quench can provide.

The Risk of Distortion and Cracking

The faster the quench, the greater the thermal stress placed on the component. This stress can cause the part to warp, distort, or even crack.

Gas quenching provides the most uniform and controlled cooling, significantly minimizing these risks. It is essential for complex geometries, thin sections, or dimensionally critical parts.

Process Cleanliness and Simplicity

Gas quenching is an exceptionally clean process. Parts emerge from the furnace bright and ready for the next step, with no need for washing.

Oil quenching, by its nature, leaves an oil residue that must be thoroughly cleaned off. This adds an extra step to production and creates waste oil that requires proper disposal.

Making the Right Choice for Your Goal

Your material's properties and final application requirements are the only factors that matter when selecting a quench method.

- If your primary focus is maximum hardness with minimal distortion for high-alloy steels: High-pressure gas quenching is the superior choice for its control, uniformity, and cleanliness.

- If your primary focus is hardening lower-alloy steels that demand a very fast cooling rate: Oil quenching is the necessary method, but you must design the process to manage the inherent risks of distortion.

- If your primary focus is softening, stress-relieving, or normalizing: A controlled slow cool in a vacuum or with low-pressure inert gas is the correct process.

Ultimately, the most successful heat treatment matches the quenching medium and its cooling power directly to the specific transformation needs of the alloy.

Summary Table:

| Quenching Method | Cooling Rate | Ideal Materials | Key Advantages | Key Disadvantages |

|---|---|---|---|---|

| High-Pressure Gas Quenching (HPGQ) | Moderate | Tool steels, high-speed steels, stainless steels | Clean process, minimal distortion, uniform cooling | May not cool fast enough for low-hardenability steels |

| Oil Quenching | Fast | Low-hardenability steels | Achieves high hardness for certain alloys | Higher risk of distortion, requires post-cleaning |

| Controlled Slow Cooling | Slow | Annealing, normalizing processes | Softens materials, refines grain structure | Not for hardening purposes |

Optimize your heat treatment processes with KINTEK's advanced vacuum furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise quenching methods to meet your unique experimental needs, enhancing efficiency and reducing distortion. Contact us today to discuss how we can support your specific alloy requirements and achieve superior results!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion