In essence, vacuum annealing furnaces are primarily used for heat-treating high-value or highly reactive materials where surface integrity and purity are critical. This includes a wide range of products from stainless steel medical devices and deep-drawn components to precision parts like bearings, cutting tools, and aerospace alloys. The process is specifically chosen when oxidation or contamination from atmospheric gases would compromise the material's properties or appearance.

The core purpose of using a vacuum for annealing is not the heat itself, but the environment it creates. By removing air, the furnace prevents oxidation at high temperatures, resulting in a clean, "bright" surface finish and preserving the material's intrinsic properties without introducing impurities.

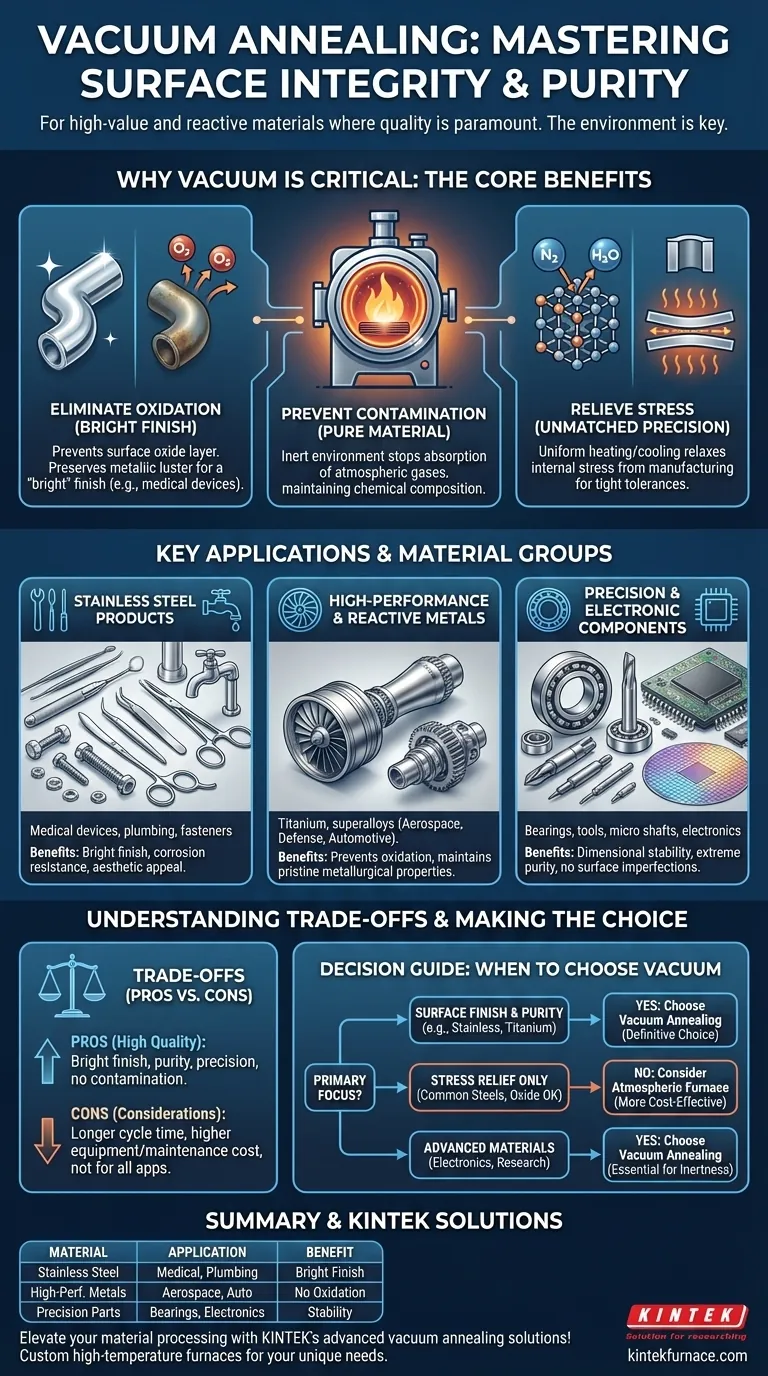

The Fundamental Principle: Why Vacuum is Critical

Annealing is a heat treatment process that alters a material's microstructure to relieve internal stresses, increase ductility, and soften it, typically after it has been hardened or shaped by manufacturing. Using a vacuum creates the ideal environment for this process to occur without negative side effects.

Eliminating Oxidation for a 'Bright' Finish

When metals are heated in the presence of oxygen, their surface reacts to form a layer of oxide, which appears as discoloration or scale. A vacuum furnace pumps out the air, removing the oxygen.

This prevents any reaction from occurring on the material's surface, preserving its original metallic luster. This specific process is known as bright annealing and is a primary reason for choosing a vacuum furnace.

Preventing Material Contamination

Atmospheric air isn't just oxygen. It contains nitrogen, moisture, and other trace elements that can be absorbed by a metal at high temperatures, a process called interstitial contamination.

This contamination can subtly but significantly alter the material's mechanical or electrical properties. A vacuum provides an inert environment, ensuring the material's chemical composition remains unchanged.

Relieving Stress with Unmatched Precision

Manufacturing processes like deep drawing (stretching metal into a shape, like a kitchen sink), stamping, or machining introduce significant internal stress. Annealing relaxes this stress.

Performing this in a vacuum allows for extremely uniform heating and cooling, ensuring that every part of the component is treated equally. This precision is vital for high-performance parts that must meet strict dimensional and structural tolerances.

Key Applications and Material Groups

The need for a clean, controlled environment dictates which industries and materials rely most heavily on vacuum annealing.

Stainless Steel Products

This is the most common application. Stainless steel's corrosion resistance and aesthetic appeal must be preserved during heat treatment.

Typical products include medical devices, plumbing equipment, water expansion components, and fasteners like screws and nails. For these items, a bright, clean finish is a mark of quality and functionality.

High-Performance and Reactive Metals

Materials like titanium and certain steel alloys are highly reactive with oxygen, especially at annealing temperatures. For them, a vacuum is not just beneficial—it's mandatory.

These materials are common in the aerospace, defense, and high-end automotive industries, where material failure is not an option and pristine metallurgical properties must be maintained.

Precision and Electronic Components

The manufacturing of bearings, watch components, cutting tools, and micro shafts requires exceptional dimensional stability and predictable mechanical properties.

Vacuum annealing provides the controlled environment needed to achieve these exact specifications without surface imperfections. Similarly, electronic materials and solar cells require extreme purity, as even minor contamination can ruin their electrical properties.

Understanding the Trade-offs

While powerful, a vacuum furnace is not the universal solution for all heat treatment. Its use is a deliberate engineering choice based on specific needs.

Cycle Time and Throughput

Creating a high-quality vacuum takes time. Pumping down the chamber, processing the parts, and then cooling them under vacuum means the overall cycle time is often longer than in a conventional atmospheric furnace. This can impact high-volume production.

Cost and Complexity

Vacuum furnaces are sophisticated pieces of equipment. They involve advanced vacuum pumps, control systems, and chamber engineering, making their initial investment and ongoing maintenance more expensive than standard furnaces.

When It's Not Necessary

For many applications, a thin layer of surface oxide is perfectly acceptable or may even be desired to help paint or other coatings adhere.

If the material is not highly reactive and the final product does not require a bright, scale-free finish, a more cost-effective atmospheric furnace is often the more practical choice.

Making the Right Choice for Your Process

Your decision to use vacuum annealing should be driven by the final requirements of your component and the nature of the material itself.

- If your primary focus is surface finish and purity: Vacuum annealing is the definitive choice, especially for stainless steel, titanium, and medical-grade components requiring a "bright" finish.

- If your primary focus is solely stress relief on common steels: An atmospheric furnace is likely more cost-effective, provided a layer of surface oxide is acceptable or will be removed in a later step.

- If your primary focus is advanced materials for electronics or research: The inert environment of a vacuum furnace is essential to prevent contamination and ensure repeatable material properties.

Ultimately, choosing vacuum annealing is a commitment to achieving the highest quality surface and metallurgical integrity for your final product.

Summary Table:

| Material/Product Type | Key Applications | Primary Benefits |

|---|---|---|

| Stainless Steel | Medical devices, plumbing, fasteners | Bright finish, corrosion resistance |

| High-Performance Metals (e.g., Titanium) | Aerospace, automotive, defense | Prevents oxidation, maintains properties |

| Precision Components | Bearings, cutting tools, electronics | Dimensional stability, no contamination |

Elevate your material processing with KINTEK's advanced vacuum annealing solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Vacuum & Atmosphere Furnaces, Muffle, Tube, Rotary Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for high-value, reactive materials. Contact us today to discuss how we can enhance your product quality and efficiency!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability