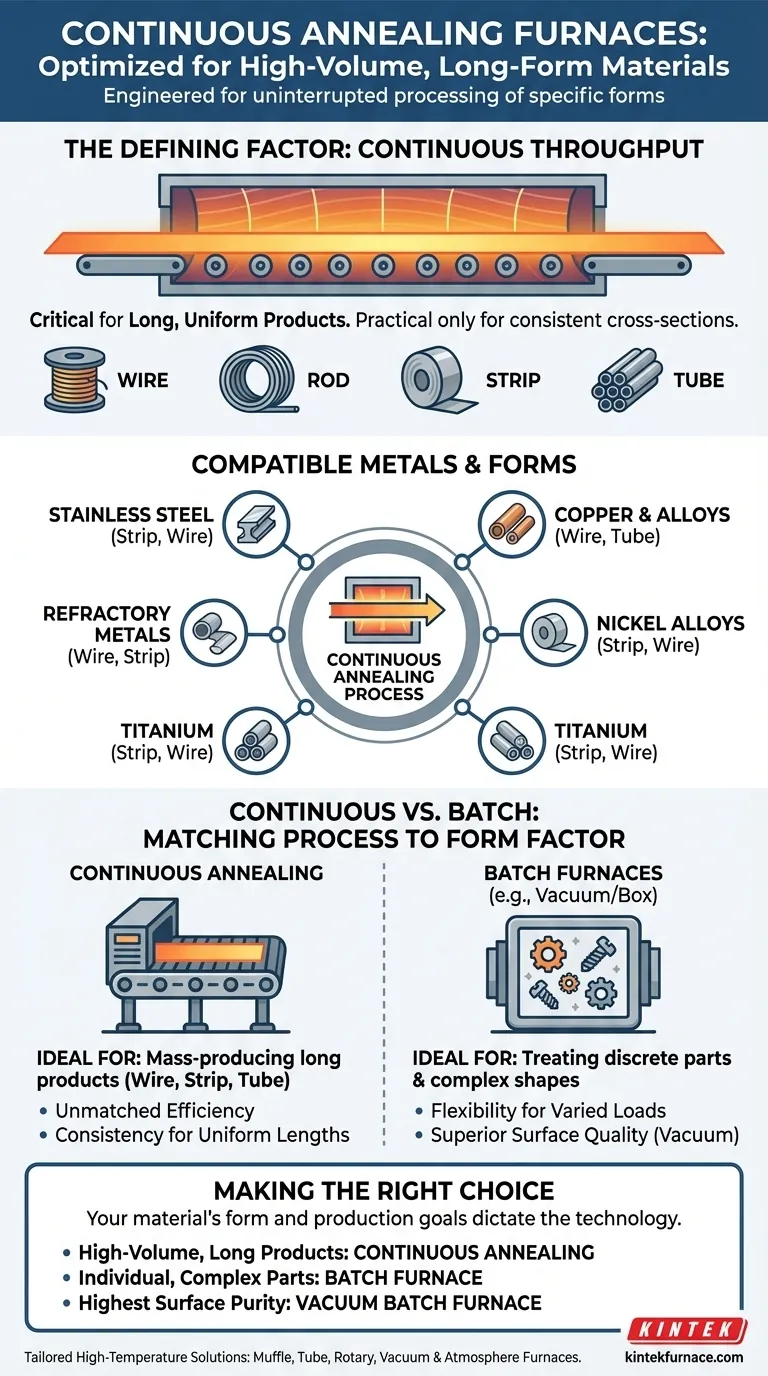

In short, continuous annealing furnaces are engineered specifically for high-volume processing of long, continuous metal products. They are primarily designed for wire, rod, strand, strip, and tube forms made from materials like stainless steel, copper and its alloys, nickel alloys, titanium, and various refractory metals.

The critical factor is not just the type of metal, but its form. Continuous annealing is a high-throughput solution optimized for long, uniform products, whereas batch furnaces handle discrete parts with varying shapes.

The Defining Factor: Continuous Throughput

The design of a continuous annealing furnace is fundamentally driven by the need to process material without interruption. This has direct implications for the types of materials and forms it can handle effectively.

Why Form Factor is Everything

A continuous furnace works by feeding material from one end, moving it through controlled heating and cooling zones, and coiling it at the other end. This process is only practical for products with a consistent cross-section that can be unspooled and re-spooled.

This is why these furnaces are tailored for wire, rod, strip, and tube products. The goal is to achieve uniform metallurgical properties along the entire length of the material, which is essential for industries like cable manufacturing or metal stamping.

The Need for High-Volume Production

These furnaces are built for industrial-scale output. They feature heavy-duty construction and energy-saving insulation to run efficiently for long periods. The entire system is optimized for consistent, repeatable results across massive quantities of material, which is not the goal when processing individual components.

A Closer Look at Compatible Metals

The metals processed in continuous annealers are chosen for their use in applications that demand long, uniform lengths. The furnace provides the precise thermal treatment needed to restore ductility and relieve internal stresses after manufacturing processes like drawing or rolling.

Ferrous Metals: Stainless Steel

Stainless steel strip and wire are commonly processed to soften them for further forming. Precise temperature and atmospheric control are crucial to prevent surface oxidation and maintain the steel's corrosion-resistant properties.

Non-Ferrous Metals: Copper, Nickel, and Titanium

Copper and copper alloys are used extensively in electrical wiring and plumbing tubes. Continuous annealing is essential for making them pliable.

Nickel, nickel chrome, and titanium are staples in the aerospace and chemical processing industries. They are often produced in strip or wire form, and continuous annealing ensures they meet strict performance specifications.

Specialized Materials: Refractory Metals

Refractory metals, which have very high melting points, also benefit from the precise and robust thermal environment of a continuous furnace. This ensures their unique properties are correctly developed for high-temperature applications.

Understanding the Trade-offs: Continuous vs. Batch Furnaces

To fully grasp where continuous annealing fits, it's helpful to compare it to batch processing methods like box or vacuum furnaces. The choice depends entirely on the product's geometry and production volume.

Continuous Annealing for Uniform Lengths

This method excels at high-volume production of a single, continuous product. It offers unmatched efficiency and consistency for wire and strip but lacks the flexibility to handle parts of different shapes and sizes.

Batch Furnaces for Discrete Parts

Box and vacuum furnaces are designed for batch processing. They are ideal for treating collections of individual items like fasteners, medical devices, watch components, or deep-drawn parts. This method offers the flexibility to handle complex geometries and varied loads, which is impossible in a continuous line.

The Role of Vacuum Furnaces

For materials like stainless steel where a perfectly clean, bright, and oxide-free surface is paramount, a vacuum furnace is often the preferred choice for batch processing. It provides a highly controlled environment for bright annealing, demagnetization, or solution treatment of finished or semi-finished parts.

Making the Right Choice for Your Goal

Your material's form and your production goals will determine the correct annealing technology.

- If your primary focus is mass-producing long products like wire or strip: A continuous annealing furnace provides the highest efficiency and consistency.

- If your primary focus is treating individual parts or components with complex shapes: A batch furnace, such as a box or vacuum furnace, offers the necessary flexibility.

- If your primary focus is the absolute highest surface quality and purity on sensitive parts: A vacuum batch furnace is the superior choice for a bright, oxide-free finish.

Ultimately, matching the annealing process to the product's form factor is the key to achieving optimal results.

Summary Table:

| Material Type | Common Forms | Key Applications |

|---|---|---|

| Stainless Steel | Strip, Wire | Corrosion-resistant parts, forming |

| Copper Alloys | Wire, Tube | Electrical wiring, plumbing |

| Nickel Alloys | Strip, Wire | Aerospace, chemical processing |

| Titanium | Strip, Wire | High-performance industries |

| Refractory Metals | Wire, Strip | High-temperature applications |

Need a tailored high-temperature furnace for your lab? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we precisely meet unique experimental requirements for industries handling wire, strip, and tube materials. Contact us today to enhance your production efficiency and achieve superior results!

Visual Guide

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What are the two main types of atmosphere furnaces and their characteristics? Choose the Right Furnace for Your Lab

- Why is moisture control critical in inert atmosphere heat treating? Prevent Oxidation and Ensure Material Integrity

- What is the significance of nitrogen in atmosphere furnaces? Unlock Enhanced Heat Treatment and Surface Hardening

- What is the relationship between temperature and the furnace atmosphere in material processing? Master the Critical Heat-Environment Balance

- What industries commonly use inert atmosphere heat treating? Key Applications in Military, Automotive, and More