In short, the Rotary Tube Tilt Furnace is designed to process a wide range of particulate materials, from fine powders to coarse granules. It accommodates various industrial heat treatments including calcination, sintering, material synthesis, and carbon activation by providing highly controlled temperature and atmospheric conditions.

The furnace's true value lies not just in what it can process, but how. Its unique combination of continuous rotation, adjustable tilt, and atmospheric control gives you precise command over thermal uniformity and material residence time, solving the common challenges of inconsistent heating and inefficient processing faced with static furnaces.

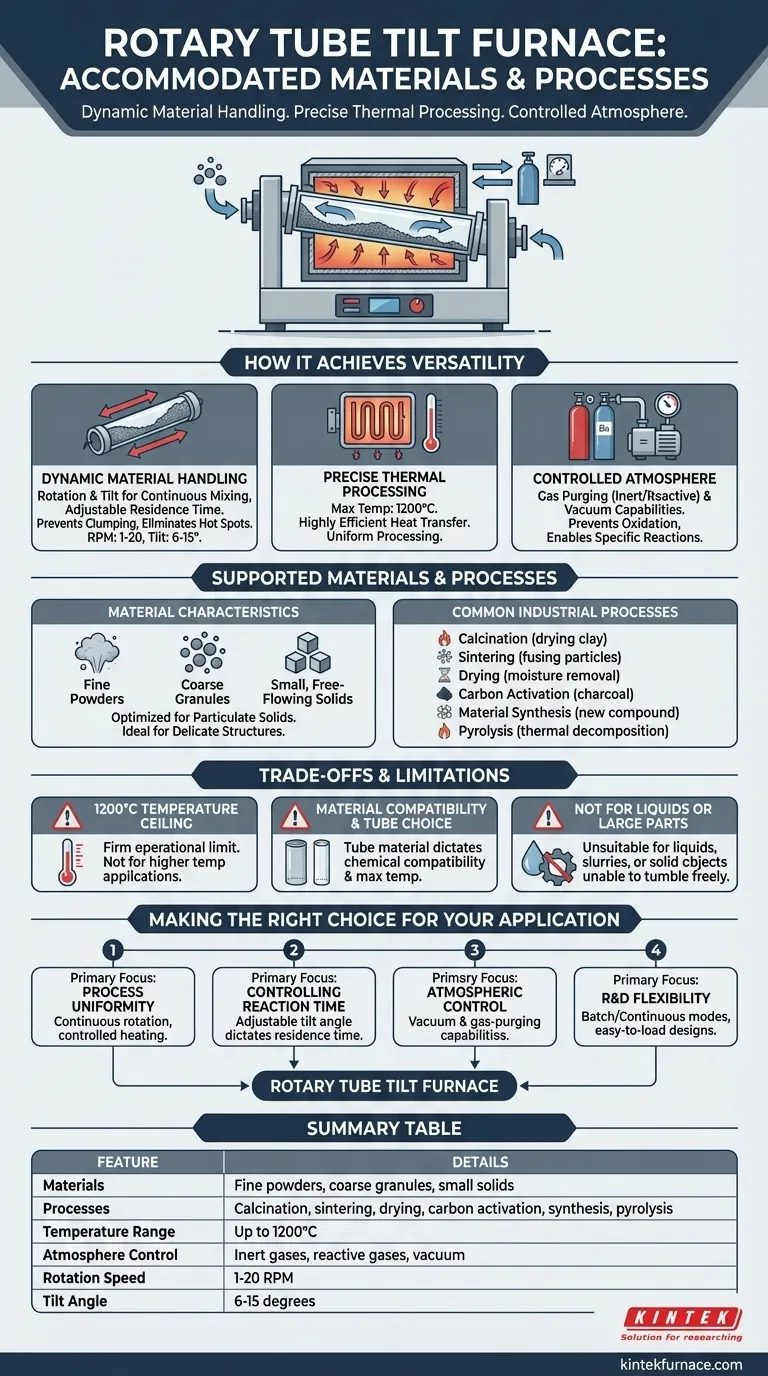

How It Achieves This Versatility

The furnace’s ability to handle diverse materials and processes stems from three core operational principles working in unison. Understanding these is key to determining if it fits your specific application.

Dynamic Material Handling via Rotation and Tilt

The furnace tube rotates at a slow, adjustable speed, typically between 1 and 20 RPM. This gentle tumbling action continuously mixes the material, ensuring every particle is uniformly exposed to the heat source.

This rotation, combined with scraper bars inside the tube, prevents clumping and eliminates the hot or cold spots common in static systems.

Furthermore, the entire furnace assembly can be tilted from 6 to 15 degrees. This angle directly controls the rate at which material flows through the tube, allowing you to precisely manage its residence time—the duration it spends in the heated zone.

Precise Thermal Processing

The furnace offers a maximum operating temperature of 1200°C, making it suitable for a majority of industrial thermal treatment applications.

Because the material is constantly in motion, heat transfer is highly efficient. This not only ensures uniform processing but can also lead to lower energy consumption compared to batch ovens where heat must soak through a static load.

Controlled Atmosphere Environments

Many advanced materials are sensitive to oxygen at high temperatures. This furnace directly addresses this with integrated gas purging and vacuum capabilities.

You can process materials under an inert gas (like nitrogen or argon) or a reactive gas, or even under a vacuum. This flexibility is critical for applications like preventing oxidation during sintering or performing specific chemical reactions on catalyst surfaces.

Supported Materials and Processes in Detail

The dynamic, controlled environment makes the Rotary Tube Tilt Furnace suitable for a broad spectrum of applications.

Material Characteristics

The design is fundamentally optimized for particulate solids. This includes:

- Fine Powders (e.g., ceramic precursors, pharmaceutical APIs)

- Coarse Granules and Pellets

- Small, free-flowing solids

Its ability to gently tumble materials makes it ideal for delicate structures that might be damaged by more aggressive mixing methods.

Common Industrial Processes

The furnace excels at processes that benefit from uniform heating and controlled residence time:

- Calcination: Removing water or volatile compounds from raw materials like clays or alumina.

- Sintering: Fusing particles together at high temperatures to create dense materials like ceramics.

- Drying: Precisely removing moisture without overheating the core material.

- Carbon Activation/Carbonization: Creating activated carbon with a high surface area.

- Material Synthesis: Forming new compounds, including advanced nanomaterials.

- Pyrolysis: Thermally decomposing organic materials in the absence of oxygen.

Understanding the Trade-offs and Limitations

No single piece of equipment is perfect for every task. To make an informed decision, you must be aware of the furnace's operational boundaries.

The 1200°C Temperature Ceiling

This is a firm operational limit. Processes requiring higher temperatures, such as the firing of certain high-performance ceramics or specific metallurgical applications, will demand a different type of furnace technology.

Material Compatibility and Tube Choice

The processing tube is a critical component. The choice between materials like quartz and alumina dictates chemical compatibility and maximum temperature. Alumina tubes are robust for higher temperatures, while quartz may be preferred for lower-temperature processes where visual observation is beneficial. The material being processed must not react with or damage the tube.

Not for Liquids or Very Large Parts

This furnace is purpose-built for powders, granules, and other particulates. It is not suitable for processing liquids, slurries, or large, solid objects that cannot tumble freely within the tube.

Making the Right Choice for Your Application

Use these points to determine if this furnace aligns with your primary processing goal.

- If your primary focus is process uniformity: The continuous rotation and controlled heating are ideal for producing high-quality, consistent batches free from hot spots.

- If your primary focus is controlling reaction time: The adjustable tilt angle gives you direct command over material residence time, which is critical for drying, calcination, and time-sensitive chemical reactions.

- If your primary focus is atmospheric control: The vacuum and gas-purging capabilities are essential for processing oxygen-sensitive materials or running reactions under specific gas environments.

- If your primary focus is process flexibility for R&D: The ability to run in both batch and continuous modes, combined with easy-to-load split furnace designs, offers significant versatility for testing diverse materials and parameters.

By understanding how the furnace's core functions address specific material challenges, you can confidently determine if it is the right tool for your work.

Summary Table:

| Feature | Details |

|---|---|

| Materials | Fine powders, coarse granules, small solids |

| Processes | Calcination, sintering, drying, carbon activation, material synthesis, pyrolysis |

| Temperature Range | Up to 1200°C |

| Atmosphere Control | Inert gases, reactive gases, vacuum |

| Rotation Speed | 1-20 RPM |

| Tilt Angle | 6-15 degrees |

Ready to enhance your lab's thermal processing with tailored solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnaces like Rotary Tube models, designed for diverse laboratories. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental needs. Contact us today to discuss how our solutions can optimize your material handling and process efficiency!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What are the key features of rotary tube furnaces regarding heat treatment? Achieve Uniform Heating and High Throughput

- Why is efficient heat transfer important in rotary tube furnaces? Boost Uniformity and Throughput

- What are some applications of rotary tube furnaces? Ideal for Continuous High-Temperature Material Processing

- How is the structure of a rotary tube furnace characterized? Discover Its Key Components and Benefits

- What are the common applications of a rotary tube furnace? Achieve Uniform Heating for Powders and Granules