Specialized vacuum furnaces are designed to execute high-temperature processes for materials that are highly reactive or require extreme purity. They augment a range of advanced manufacturing techniques, including chemical vapor deposition (CVD), graphitization, graphite purification, induction melting, and vacuum sintering. These processes are critical for producing components from advanced ceramics, high-purity graphite, magnet materials, and reactive or refractory metals like tungsten and molybdenum.

The core value of a specialized vacuum furnace is not simply the application of heat, but the creation of a precisely controlled, inert environment. This control prevents unwanted chemical reactions like oxidation and enables purification and synthesis processes that are impossible to achieve in a standard atmosphere.

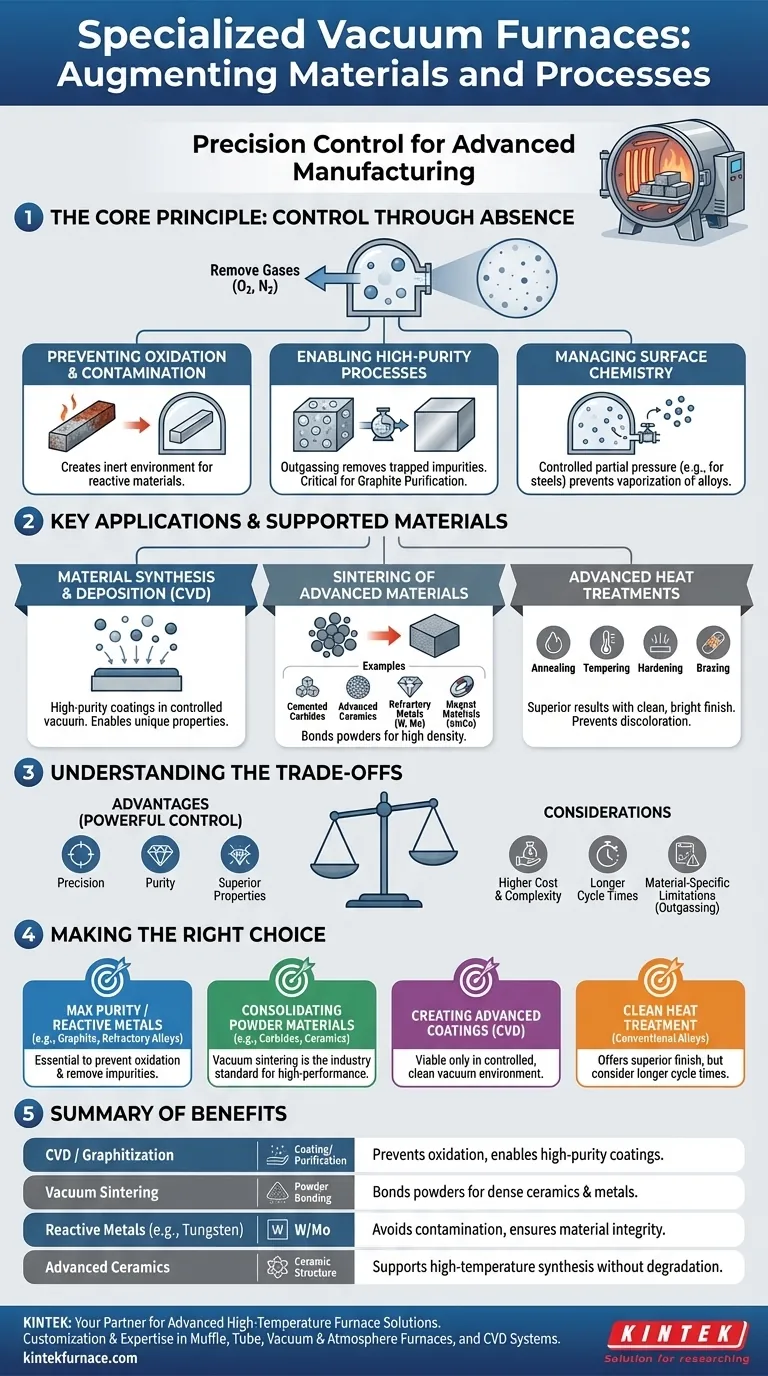

The Core Principle: Control Through Absence

A vacuum is not merely empty space; in materials science, it is an active tool. By removing atmospheric gases like oxygen and nitrogen, engineers gain precise control over the chemical environment at elevated temperatures, which is fundamental to modern material processing.

Preventing Oxidation and Contamination

At high temperatures, most metals become highly reactive with oxygen. This reaction, oxidation, forms a brittle oxide layer on the material's surface, compromising its structural integrity and performance.

A vacuum furnace removes the reactive gases, creating an inert environment. This allows materials to be heated, sintered, or brazed without degradation, which is critical for applications in aerospace and electronics where material failure is not an option.

Enabling High-Purity Processes

Certain processes are fundamentally about removing impurities. A vacuum is essential for workload outgassing, where trapped gases within a material are drawn out and removed.

This principle is also central to graphite purification, where a vacuum environment facilitates the vaporization and removal of contaminants to achieve the high purity levels required for semiconductor and nuclear applications.

Managing Surface Chemistry

A vacuum allows for the use of partial pressure, where a specific, low-pressure gas is intentionally introduced into the chamber. This technique offers an even finer level of control.

For example, when heat-treating certain steels, partial pressure can be used to manage the vaporization of chromium from the alloy's surface. This prevents depletion of critical alloying elements and ensures the material retains its intended properties.

Key Applications and Supported Materials

Specialized vacuum furnaces are not a one-size-fits-all solution. Their design is often tailored to a specific process, enabling the creation of materials with unique properties.

Material Synthesis and Deposition

Chemical Vapor Deposition (CVD) is a process where precursor gases are introduced into the furnace to react and form a solid, high-purity coating on a substrate. This is only possible in a controlled vacuum that prevents unwanted side reactions.

Sintering of Advanced Materials

Vacuum sintering is the process of heating compacted material powders to just below their melting point, causing the particles to bond and form a solid, dense object.

This is a primary manufacturing method for cemented carbides, advanced ceramics, refractory metals like tungsten and molybdenum, and permanent magnet materials such as samarium cobalt.

Advanced Heat Treatments

Many conventional heat treatments are enhanced when performed in a vacuum. Processes like annealing, tempering, hardening, and brazing gain superior results.

Performing these in a vacuum prevents surface discoloration and oxidation, yielding a clean, bright finish that often eliminates the need for post-processing cleanup.

Understanding the Trade-offs

While powerful, vacuum furnaces introduce their own set of considerations that differ from conventional atmospheric furnaces.

Higher Cost and Complexity

Vacuum furnaces are inherently more complex systems. They require vacuum pumps, sophisticated seals, and precise control instrumentation, leading to a higher initial investment and more intensive maintenance.

Longer Cycle Times

Achieving a deep vacuum is not instantaneous. The time required to pump down the chamber, run the thermal process, and then cool and backfill the system often results in longer overall cycle times compared to atmospheric processing.

Material-Specific Limitations

Some materials can outgas significantly when heated in a vacuum, releasing volatile elements that can contaminate the furnace or alter the material's own composition. Managing this often requires careful process control, such as the use of partial pressure.

Making the Right Choice for Your Goal

The decision to use a specialized vacuum furnace depends entirely on your material's sensitivity and the required properties of the final product.

- If your primary focus is achieving maximum material purity or working with reactive metals: A vacuum furnace is essential to prevent oxidation and remove impurities, as seen in graphite purification and processing refractory alloys.

- If your primary focus is consolidating powder-based materials into high-density parts: Vacuum sintering is the industry standard for creating high-performance components from cemented carbides, ceramics, and refractory metals.

- If your primary focus is creating advanced coatings or novel structures: Processes like Chemical Vapor Deposition (CVD) are only viable in the controlled, clean environment a vacuum furnace provides.

- If your primary focus is clean, high-quality heat treatment of conventional alloys: A vacuum furnace offers superior results by preventing surface reactions, but its longer cycle times must be weighed against production demands.

Ultimately, leveraging a vacuum furnace is a strategic decision to gain absolute control over your material's environment, ensuring its final properties meet the most demanding specifications.

Summary Table:

| Process/Material | Key Benefits |

|---|---|

| CVD / Graphitization | Prevents oxidation, enables high-purity coatings |

| Vacuum Sintering | Bonds powders for dense ceramics and metals |

| Reactive Metals (e.g., Tungsten) | Avoids contamination, ensures material integrity |

| Advanced Ceramics | Supports high-temperature synthesis without degradation |

Ready to elevate your material processing with precision and purity? KINTEK specializes in advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With our strong R&D and deep customization capabilities, we tailor our products to meet your unique experimental needs—whether you're working with reactive metals, ceramics, or other advanced materials. Contact us today to discuss how our expertise can optimize your processes and deliver superior results!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What are the development prospects of atmosphere box furnaces in the aerospace industry? Unlock Advanced Material Processing for Aerospace Innovation

- What is inert gas technology used for in high-temperature atmosphere vacuum furnaces? Protect Materials and Speed Up Cooling

- How does the pressure range change under vacuum conditions in an atmosphere box furnace? Explore Key Shifts for Material Processing

- How does a mixed gas flow control system maintain stability during high-temperature nitriding? Precision Gas Ratios

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas