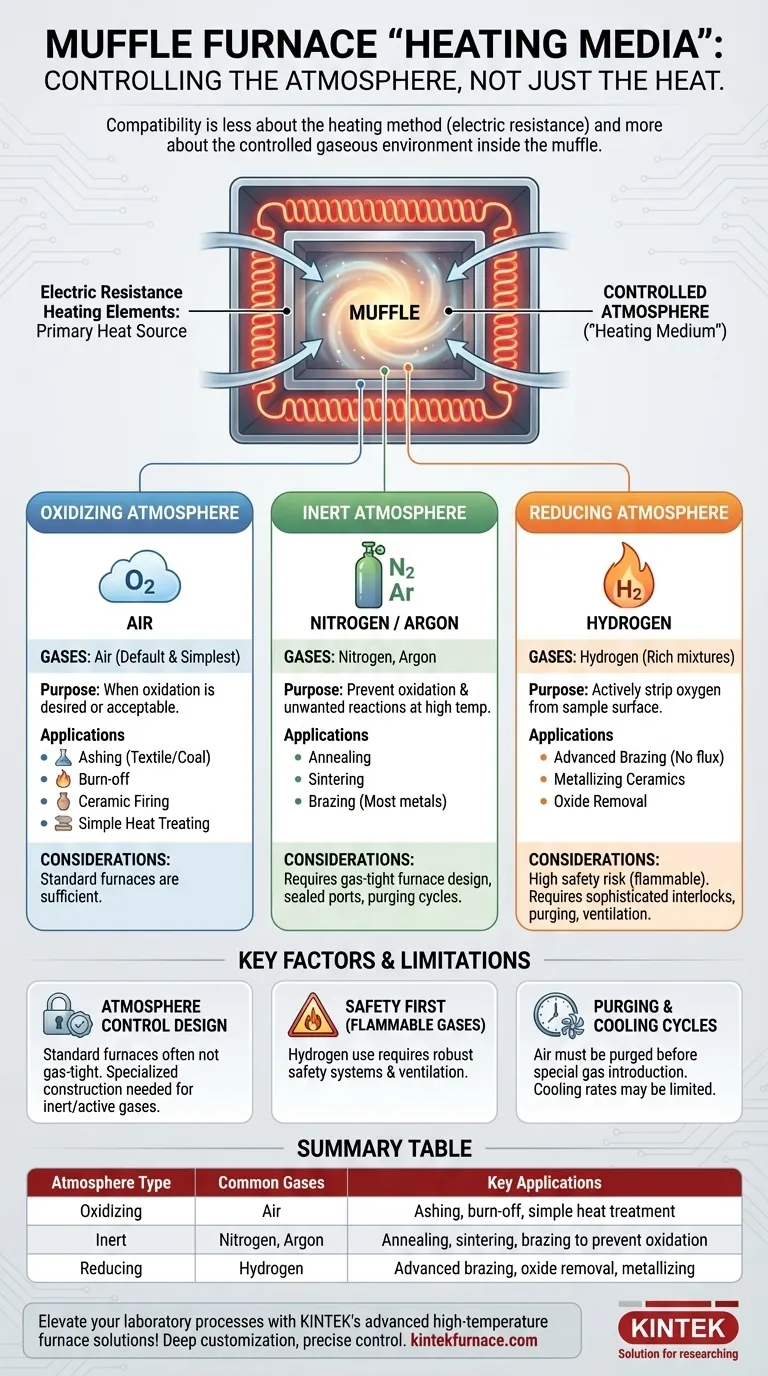

At its core, a muffle furnace's compatibility is less about the heating method and more about the controlled atmosphere it can maintain. Standard muffle furnaces operate with air, but specialized models are designed to use a variety of gaseous "heating media"—more accurately, process atmospheres—including inert gases like nitrogen and active gases like hydrogen or gas mixtures.

The choice of gas inside a muffle furnace is not about heating the chamber, but about controlling the chemical environment. The specific process you are performing, such as ashing, annealing, or brazing, dictates whether you need an oxidizing (air), inert (nitrogen), or reducing (hydrogen) atmosphere.

Deconstructing the "Heating Medium"

The term "heating medium" can be misleading. It's crucial to distinguish between the furnace's heat source and the atmosphere surrounding the sample.

The Primary Heating System: Electric Resistance

Nearly all modern muffle furnaces, from benchtop lab models to large industrial units, use electric resistance heating elements. These elements are positioned outside the central chamber (the "muffle"), heating its walls. The heat then radiates into the chamber to process the sample.

The brand names you might encounter—like Thermolyne, Carbolite, or Nabertherm—are not different types of heating media. They are manufacturers offering furnaces with different temperature ranges, chamber sizes, and features.

The Internal Atmosphere: A Controlled Environment

The "medium" you asked about is the gas inside the muffle. This gas creates a specific chemical atmosphere. The purpose of the muffle is to separate the workload from the heating elements, allowing this atmosphere to be controlled without damaging the elements.

Common Atmospheres and Their Applications

The atmosphere you choose is entirely dependent on your process goals.

Oxidizing Atmosphere (Air)

Air is the default, most common, and simplest atmosphere. It is used when oxidation is either desired or will not negatively affect the outcome.

Common applications include ashing (textile or coal analysis), burn-off, certain ceramic firing processes, and simple heat-treating of non-reactive materials.

Inert Atmosphere (Nitrogen or Argon)

An inert atmosphere is used to prevent oxidation and other unwanted chemical reactions at high temperatures. The chamber is purged of air and filled with a gas like nitrogen or argon.

This is critical for processes like annealing, sintering, and brazing of most metals, which would be ruined by the formation of surface oxides.

Active or Reducing Atmosphere (Hydrogen)

Certain advanced processes require an active atmosphere that chemically interacts with the sample. A hydrogen-rich atmosphere is a reducing environment, meaning it will actively strip oxygen atoms from a material.

This is used for applications like copper brazing without flux, metallizing ceramics, or heat-treating specific alloys where a perfectly clean, oxide-free surface is non-negotiable.

Understanding the Trade-offs and Limitations

Using a controlled atmosphere is not as simple as attaching a gas cylinder to any furnace.

Atmosphere Control Requires a Specific Design

A standard muffle furnace designed for use in air is often not sealed sufficiently to maintain an inert atmosphere. Using special gases requires a furnace built with gas-tight construction, including sealed doors and ports for gas inlet and outlet.

Safety with Flammable Gases is Paramount

Using flammable gases like hydrogen introduces significant safety risks. Furnaces designed for these atmospheres must have sophisticated safety interlocks, purging systems, and ventilation to prevent explosive mixtures of gas and air.

Purging and Cooling Cycles

Before introducing a special atmosphere, the air must be purged from the chamber, which adds a step to the process. Likewise, cooling is often a simple fan-assisted exhaust, meaning controlled cooling rates can be limited without more advanced furnace models.

Making the Right Choice for Your Process

Your application dictates the furnace and atmosphere you need.

- If your primary focus is ashing, burn-off, or simple heat treatment: A standard muffle furnace operating with a normal air atmosphere is sufficient.

- If your primary focus is preventing oxidation for annealing or sintering: You must use a furnace designed for controlled atmospheres with an inert gas like nitrogen.

- If your primary focus is actively removing surface oxides for advanced brazing: You require a specialized furnace rated for reducing gases like hydrogen, with all necessary safety systems.

Ultimately, matching the furnace's atmospheric capability to your specific chemical processing goal is the key to a successful outcome.

Summary Table:

| Atmosphere Type | Common Gases | Key Applications |

|---|---|---|

| Oxidizing | Air | Ashing, burn-off, simple heat treatment |

| Inert | Nitrogen, Argon | Annealing, sintering, brazing to prevent oxidation |

| Reducing | Hydrogen | Advanced brazing, oxide removal, metallizing |

Elevate your laboratory processes with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer a diverse product line including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, whether you need precise temperature control, uniform heating, or specialized atmosphere handling. Don't let compatibility issues hold you back—contact us today to discuss how our tailored solutions can optimize your applications like ashing, annealing, and brazing for superior results and efficiency!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation