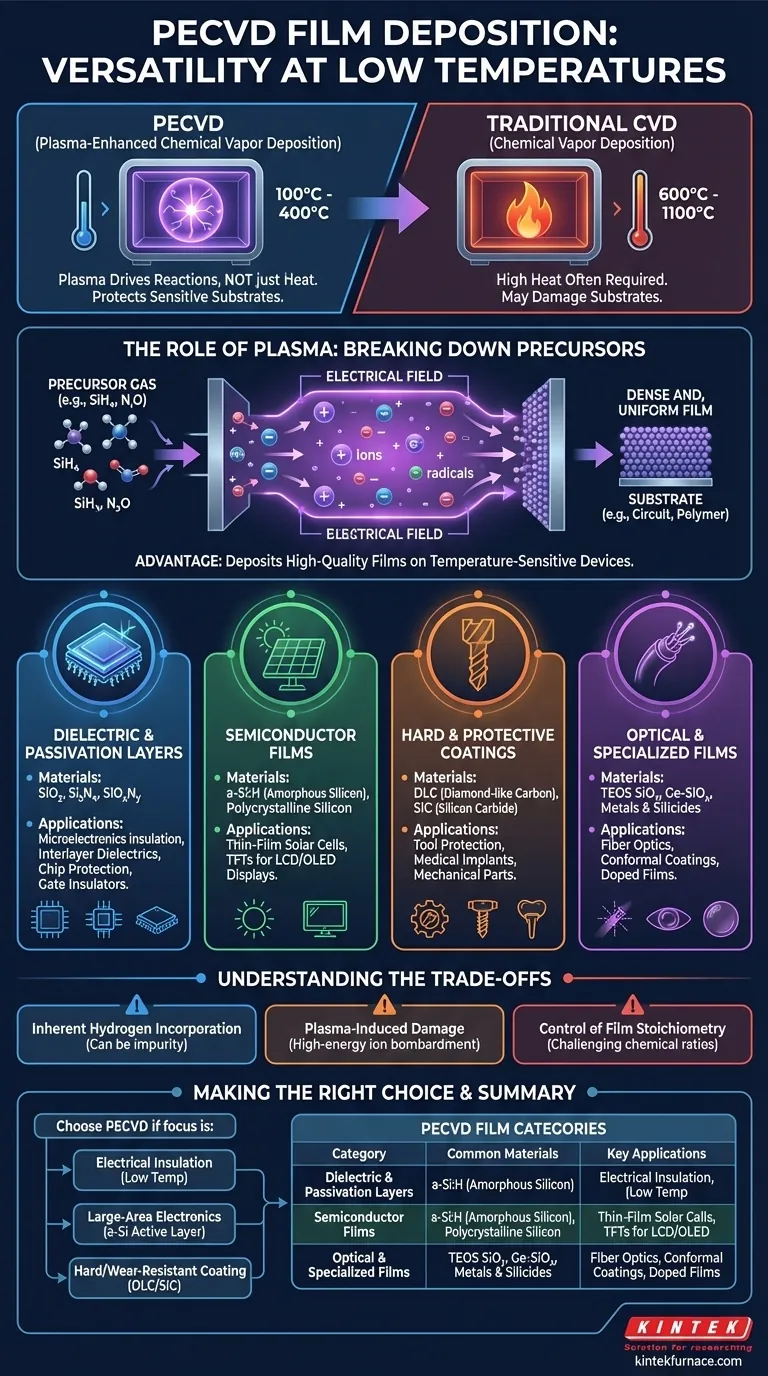

In short, Plasma-Enhanced Chemical Vapor Deposition (PECVD) is a highly versatile technique capable of depositing a wide range of thin films. The most common materials include dielectrics like silicon dioxide (SiO₂) and silicon nitride (Si₃N₄), semiconductor films such as amorphous silicon (a-Si:H), and hard protective coatings like diamond-like carbon (DLC) and silicon carbide (SiC).

The fundamental advantage of PECVD is its ability to deposit high-quality, dense, and uniform films at significantly lower temperatures than traditional Chemical Vapor Deposition (CVD). This makes it the go-to method for coating temperature-sensitive substrates or devices with existing structures.

Why PECVD Excels: The Role of Plasma

The key to PECVD's capabilities lies in its use of plasma to drive chemical reactions, rather than relying solely on high thermal energy. This distinction is the source of its primary benefits.

Breaking Down Precursors at Low Temperatures

In a PECVD system, an electrical field is used to ionize precursor gases, creating a reactive plasma. This plasma contains a mix of ions, electrons, and highly reactive free radicals.

These energized species can react and form a solid film on a substrate at temperatures typically between 100°C and 400°C. This is a dramatic reduction from the 600°C to 1100°C often required for thermal CVD processes.

Protecting Temperature-Sensitive Substrates

The low-temperature nature of PECVD is its most critical feature. It allows for the deposition of films on substrates that would be damaged or destroyed by high heat.

This includes completed integrated circuits with aluminum or copper metallization, polymer-based flexible electronics, and various optical components.

A Breakdown of Common PECVD Films

The versatility of PECVD is best understood by categorizing the types of films it can produce. Each category serves a distinct set of industrial and research applications.

Dielectric and Passivation Layers

This is the most common application for PECVD. These insulating films are crucial for manufacturing microelectronics.

Materials include silicon dioxide (SiO₂), silicon nitride (Si₃N₄), and silicon oxynitride (SiOxNy). They are used as interlayer dielectrics, final passivation layers to protect chips from moisture and contamination, and as gate insulators in transistors.

Semiconductor Films

PECVD is a dominant technology for depositing active semiconductor layers, particularly for large-area electronics.

The most notable material is hydrogenated amorphous silicon (a-Si:H), which forms the active layer in many thin-film solar cells and thin-film transistors (TFTs) used in LCD displays. The process also allows for the deposition of polycrystalline silicon.

Hard and Protective Coatings

The high ion energy in the plasma can be leveraged to create exceptionally hard and durable films.

Diamond-like carbon (DLC) films are prized for their extreme hardness, low friction coefficient, and chemical inertness, making them ideal for protecting tools, medical implants, and mechanical components. Silicon carbide (SiC) offers similar benefits with high thermal stability.

Optical and Specialized Films

The precise control over film properties allows for specialized applications. PECVD can produce TEOS SiO₂ (from a tetraethyl orthosilicate precursor), known for its excellent ability to conformally coat and fill gaps in complex topographies.

It can also be used to create doped films, such as germanium-doped silicon oxide (Ge-SiOx) for fiber optics, or even deposit certain metals and their silicides.

Understanding the Trade-offs

While powerful, PECVD is not without its complexities. An expert must understand its limitations to deploy it effectively.

Inherent Hydrogen Incorporation

Because many precursor gases are hydrogen-based (e.g., silane, SiH₄), hydrogen atoms are often incorporated into the deposited film. While this is essential for passivating defects in amorphous silicon (a-Si:H), it can be an unwanted impurity in other films, potentially affecting their electrical or optical properties.

Potential for Plasma-Induced Damage

The high-energy ions that drive the deposition reaction can also bombard the substrate surface. This can induce stress, create defects in the underlying material, or damage sensitive electronic device structures. Careful process tuning is required to balance deposition rate with minimizing damage.

Control of Film Stoichiometry

Achieving a precise chemical ratio (stoichiometry) in complex films like silicon oxynitride (SiOxNy) can be challenging. The final composition depends on a complex interplay of gas flows, pressure, plasma power, and temperature, requiring careful process development and characterization.

Making the Right Choice for Your Goal

Selecting a deposition method depends entirely on the film's purpose and the substrate's limitations. PECVD should be your primary consideration under these circumstances.

- If your primary focus is electrical insulation on a completed device: PECVD is the industry standard for depositing SiO₂ and Si₃N₄ passivation layers due to its low process temperature.

- If your primary focus is manufacturing large-area electronics like displays or solar cells: PECVD is the essential technology for creating high-quality amorphous silicon active layers.

- If your primary focus is a hard, wear-resistant coating on a mechanical part: PECVD is a superior choice for depositing DLC or SiC films with excellent adhesion and durability.

- If your primary focus is achieving the highest possible crystal quality or film purity: You may need to consider higher-temperature methods like thermal CVD or molecular-beam epitaxy (MBE), provided your substrate can withstand the heat.

Ultimately, PECVD is a cornerstone of modern materials engineering, empowering the creation of advanced films on virtually any substrate.

Summary Table:

| Film Category | Common Materials | Key Applications |

|---|---|---|

| Dielectric Layers | SiO₂, Si₃N₄, SiOxNy | Microelectronics insulation, passivation |

| Semiconductor Films | a-Si:H, polycrystalline silicon | Solar cells, TFTs in displays |

| Protective Coatings | DLC, SiC | Hard coatings for tools, medical implants |

| Optical Films | TEOS SiO₂, Ge-SiOx | Fiber optics, conformal coatings |

Unlock the potential of PECVD for your laboratory with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide high-temperature furnaces like CVD/PECVD Systems tailored for diverse labs. Our deep customization capability ensures precise fit for unique experimental needs, helping you deposit superior thin films efficiently. Contact us today to discuss how we can enhance your research and production processes!

Visual Guide

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

People Also Ask

- How does chemical vapour deposition (CVD) differ from PVD? Key Differences in Thin-Film Coating Methods

- What is PECVD specification? A Guide to Choosing the Right System for Your Lab

- What parameters control the quality of PECVD-deposited films? Master Key Variables for Superior Film Properties

- How is silicon dioxide deposited from tetraethylorthosilicate (TEOS) in PECVD? Achieve Low-Temperature, High-Quality SiO2 Films

- What are the drawbacks of CVD compared to PECVD? Key Limitations for Your Lab