At their core, dental sintering furnaces are used to process restorations made from zirconia. After a dental lab mills a crown, bridge, or framework from a block of pre-sintered zirconia, the furnace performs the critical final step of heating the material to transform it into a dense, high-strength final product.

The key insight is that sintering is not defined by the type of restoration (e.g., a crown vs. a bridge), but by the material used. The process is essential for zirconia, transforming it from a soft, chalk-like state into its final, durable form.

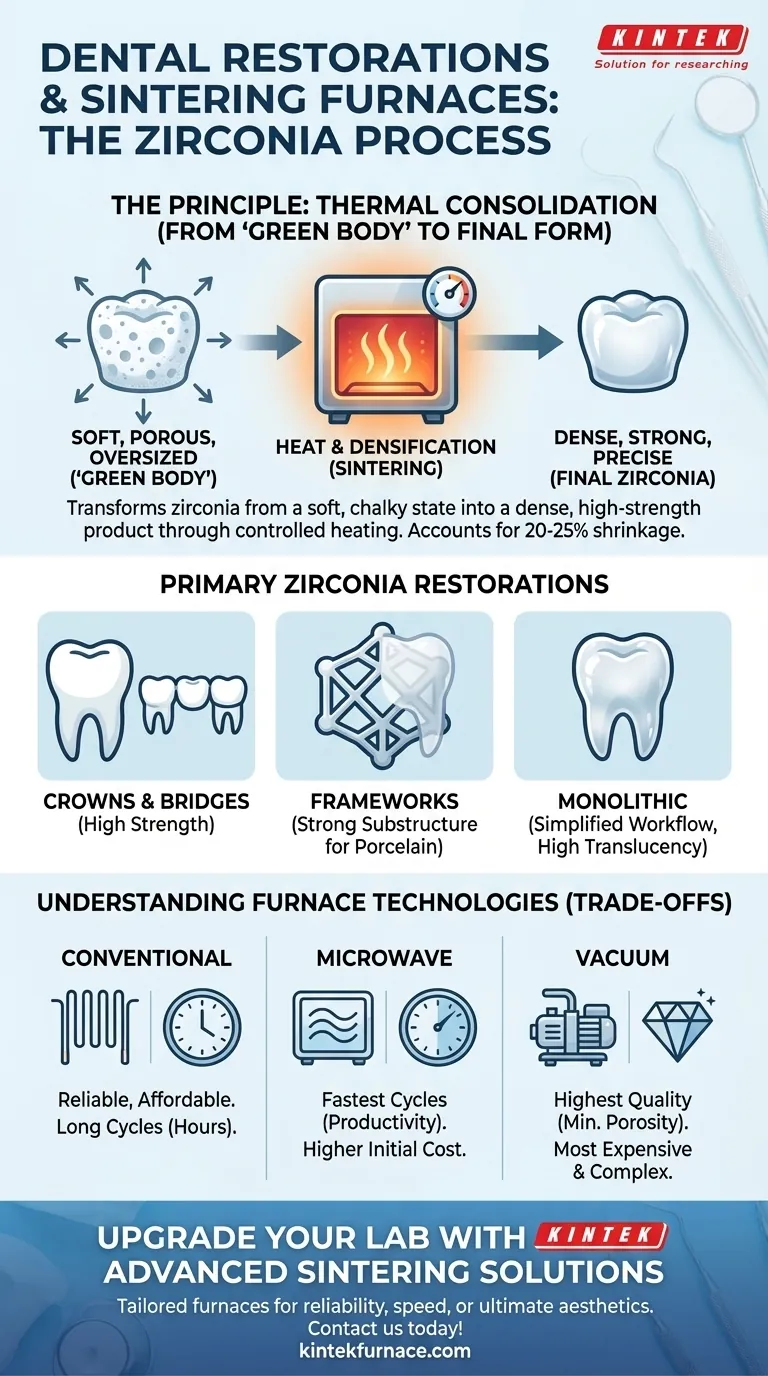

The Principle: Why Sintering is Necessary

Sintering is a process of thermal consolidation. It's the critical link between the digital design of a restoration and its final physical strength and fit in a patient's mouth.

From "Green Body" to Final Form

When a zirconia restoration is first milled, it is in a soft, chalky, and oversized state often called a "green body" or "white stage." It is porous and lacks the strength required for clinical use.

The sintering furnace heats this green body to a precise temperature, typically below the material's melting point. This heat causes the individual zirconia particles to fuse, drastically reducing porosity and increasing density.

The Critical Role of Shrinkage

During this densification process, the restoration shrinks significantly—often by 20-25%.

This shrinkage is not a flaw; it's a calculated part of the manufacturing process. CAD/CAM software automatically accounts for this by directing the milling machine to create a restoration that is precisely oversized by the material's specific shrinkage factor.

Achieving Final Strength and Aesthetics

The sintering cycle is what imparts the final properties to the zirconia. The process determines the material's final strength, fracture toughness, and translucency.

Proper sintering ensures the restoration can withstand the forces of chewing and that its color and optical properties match the surrounding teeth.

Primary Restorations Processed via Sintering

While any zirconia restoration requires sintering, the most common applications fall into several key categories.

Crowns and Bridges

Single crowns and multi-unit bridges are the most common restorations processed in sintering furnaces. The strength achieved through sintering makes zirconia an ideal material for both anterior and posterior restorations.

Frameworks for Porcelain Overlays

Initially, zirconia was primarily used as a strong substructure or "framework." A dental technician would then layer porcelain over this framework to achieve the final aesthetics. The sintering step is what gives this core its immense strength.

Monolithic Restorations

Modern advancements in zirconia have led to materials with higher translucency. This allows labs to create "monolithic" restorations, which are milled from a single block of zirconia and require no porcelain overlay. This simplifies the workflow, and sintering remains the key final step.

Understanding the Trade-offs: Furnace Technologies

Not all sintering furnaces are the same. The technology used impacts speed, cost, and the final quality of the restoration.

Conventional Sintering Furnaces

These furnaces use traditional resistive heating elements. They are the most common and affordable type of furnace, known for their reliability. However, their primary drawback is a long sintering cycle, which can take several hours.

Microwave Sintering Furnaces

These newer furnaces use microwave energy to heat the zirconia. This results in a much faster sintering cycle, significantly improving a lab's productivity. The trade-off is a higher initial investment cost.

Vacuum Sintering Furnaces

For the highest possible quality, some advanced furnaces incorporate a vacuum during the heating cycle. The vacuum helps remove any microscopic air pockets, reducing porosity to an absolute minimum. This yields restorations with superior density and translucency but represents the most expensive and complex option.

Applying This to Your Lab's Goal

Understanding the process and technology allows you to align your equipment with your specific production needs.

- If your primary focus is reliability and managing initial cost: A conventional sintering furnace provides a proven, effective solution for producing high-quality zirconia restorations.

- If your primary focus is high-volume production and turnaround time: A microwave sintering furnace is a necessary investment to dramatically reduce cycle times and increase throughput.

- If your primary focus is producing the highest-end aesthetic restorations: A vacuum sintering furnace will provide the greatest material density and translucency, though it requires a larger budget and more expertise.

Mastering the sintering process is fundamental to delivering durable and aesthetic restorations in modern digital dentistry.

Summary Table:

| Restoration Type | Material | Key Benefits |

|---|---|---|

| Crowns and Bridges | Zirconia | High strength, durability for chewing forces |

| Frameworks for Porcelain Overlays | Zirconia | Strong substructure for aesthetic overlays |

| Monolithic Restorations | Zirconia | Simplified workflow, no porcelain needed |

Upgrade your dental lab with KINTEK's advanced sintering furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental needs for zirconia restorations. Contact us today to enhance your production efficiency and achieve superior results!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations