At its core, a vacuum annealing furnace is designed to meet any annealing need where surface chemistry and material purity are paramount. It excels at common processes like stress relief and recrystallization annealing, but its true value lies in performing these tasks in a highly controlled, inert environment that prevents oxidation and other surface contamination.

The fundamental purpose of using a vacuum furnace for annealing is not just to soften a material, but to do so without altering its surface. This guarantees a pristine, bright finish and preserves the material's inherent properties, a result often unattainable with conventional atmospheric furnaces.

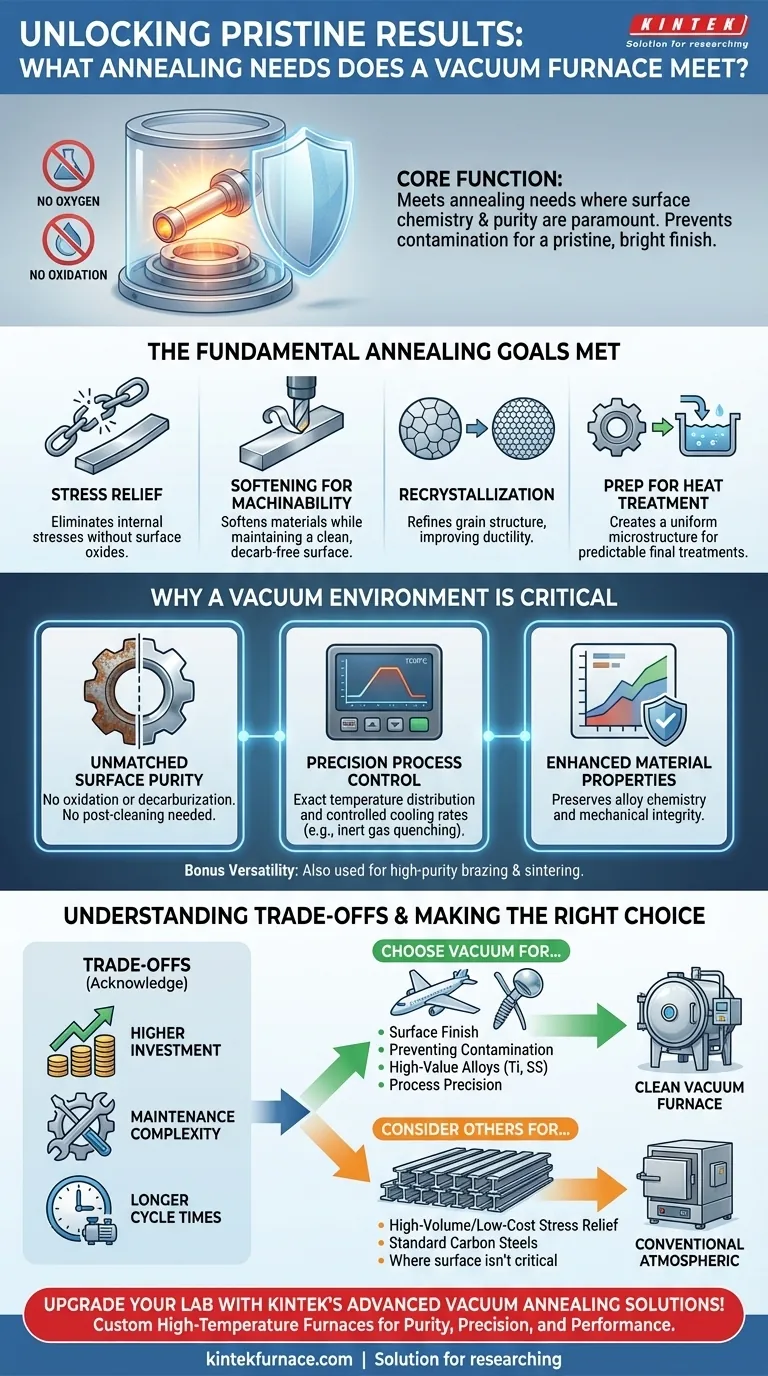

The Fundamental Annealing Goals Met by a Vacuum Furnace

A vacuum furnace achieves the primary objectives of annealing with superior control and cleanliness. It addresses the structural and mechanical needs of a workpiece at a fundamental level.

Eliminating Internal Stress (Stress Relief)

A key function is to relieve residual stresses induced by manufacturing processes like casting, forging, welding, or machining. By heating the material in a vacuum, these stresses are neutralized without introducing surface oxides, preventing future deformation or cracking.

Softening Materials for Machinability

The annealing process softens workpieces, making them easier to cut, form, or machine. A vacuum furnace performs this softening while ensuring the material surface remains clean and free from decarburization, which is critical for subsequent processing steps.

Refining Grain Structure (Recrystallization)

For materials that have been cold-worked, vacuum annealing facilitates recrystallization. This process refines the material's grain structure, improving ductility and overall mechanical properties to meet specific performance requirements.

Preparing for Subsequent Heat Treatment

Annealing is often a preparatory step for final heat treatments like quenching and tempering. A vacuum furnace creates an ideal, uniform microstructure, ensuring that the material responds predictably and consistently to these final, critical treatments.

Why a Vacuum Environment is Critical

The decision to use a vacuum furnace is driven by the significant advantages the vacuum environment itself provides over a standard atmosphere. These benefits are directly tied to the absence of oxygen and other reactive gases.

Unmatched Surface Purity

This is the principal advantage. In a vacuum, there is no oxygen to react with the hot metal surface. This completely prevents oxidation (scaling) and decarburization (carbon loss from the surface of steel), resulting in a smooth, bright, and clean part that requires no post-process cleaning.

Precision Process Control

Modern vacuum furnaces offer exceptional control over the entire heat treatment cycle. Automated systems with PID/PLC controllers allow for precise temperature ramping, uniform heat distribution, and highly controlled cooling rates using inert gas quenching, ensuring repeatable and predictable results.

Enhanced Material Properties

By preventing surface reactions, the furnace preserves the alloy's intended chemistry and mechanical characteristics. The clean processing environment ensures that the improvements from annealing—like refined grain structure and stress relief—are not compromised by surface-level contamination.

Versatility Beyond Annealing

While exceptional for annealing, the capabilities of a vacuum furnace often extend to other thermal processes. Many units are also used for high-purity metal brazing and the sintering of powdered metals, adding significant value and versatility to a manufacturing operation.

Understanding the Trade-offs

While powerful, vacuum furnaces are not the universal solution for every annealing task. An objective assessment requires acknowledging their specific challenges.

Higher Initial Investment

Vacuum furnaces are complex systems incorporating sophisticated vacuum pumps, seals, and control systems. This results in a significantly higher initial capital cost compared to simpler, conventional atmospheric furnaces.

Maintenance Complexity

The vacuum system, including pumps, valves, and chamber seals, requires regular and specialized maintenance to ensure it can achieve and hold the required vacuum level. This can lead to higher long-term operational costs and requires skilled technicians.

Cycle Time Considerations

Achieving a deep vacuum (pumping down the chamber) adds time to the beginning of every process cycle. For high-volume, low-margin parts where surface finish is not critical, the longer cycle times may be a disadvantage compared to continuous atmospheric furnaces.

Making the Right Choice for Your Application

Selecting the right furnace depends entirely on your material, your end-goal, and your budget.

- If your primary focus is surface finish and preventing contamination: A vacuum furnace is the superior choice, especially for reactive metals like titanium, stainless steels, and high-value alloys.

- If your primary focus is high-volume, low-cost stress relief on standard carbon steels: A conventional atmospheric furnace is often the more cost-effective and faster solution.

- If your primary focus is process precision for advanced materials or electronics: The tight control and clean environment of a vacuum furnace are essential for achieving specific microstructures and performance characteristics.

Ultimately, choosing a vacuum furnace is an investment in quality, purity, and process control.

Summary Table:

| Annealing Need | Key Benefit of Vacuum Furnace |

|---|---|

| Stress Relief | Eliminates internal stress without oxidation or surface contamination |

| Softening for Machinability | Softens materials while maintaining clean, decarb-free surfaces |

| Recrystallization | Refines grain structure to improve ductility and mechanical properties |

| Preparation for Further Treatment | Creates uniform microstructure for predictable final heat treatments |

Upgrade your lab's capabilities with KINTEK's advanced vacuum annealing solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace options like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements for purity, precision, and performance. Contact us today to discuss how our tailored solutions can enhance your heat treatment processes and deliver superior results for materials like stainless steel and titanium!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What is the role of vacuum pumps in a vacuum heat treatment furnace? Unlock Superior Metallurgy with Controlled Environments

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control