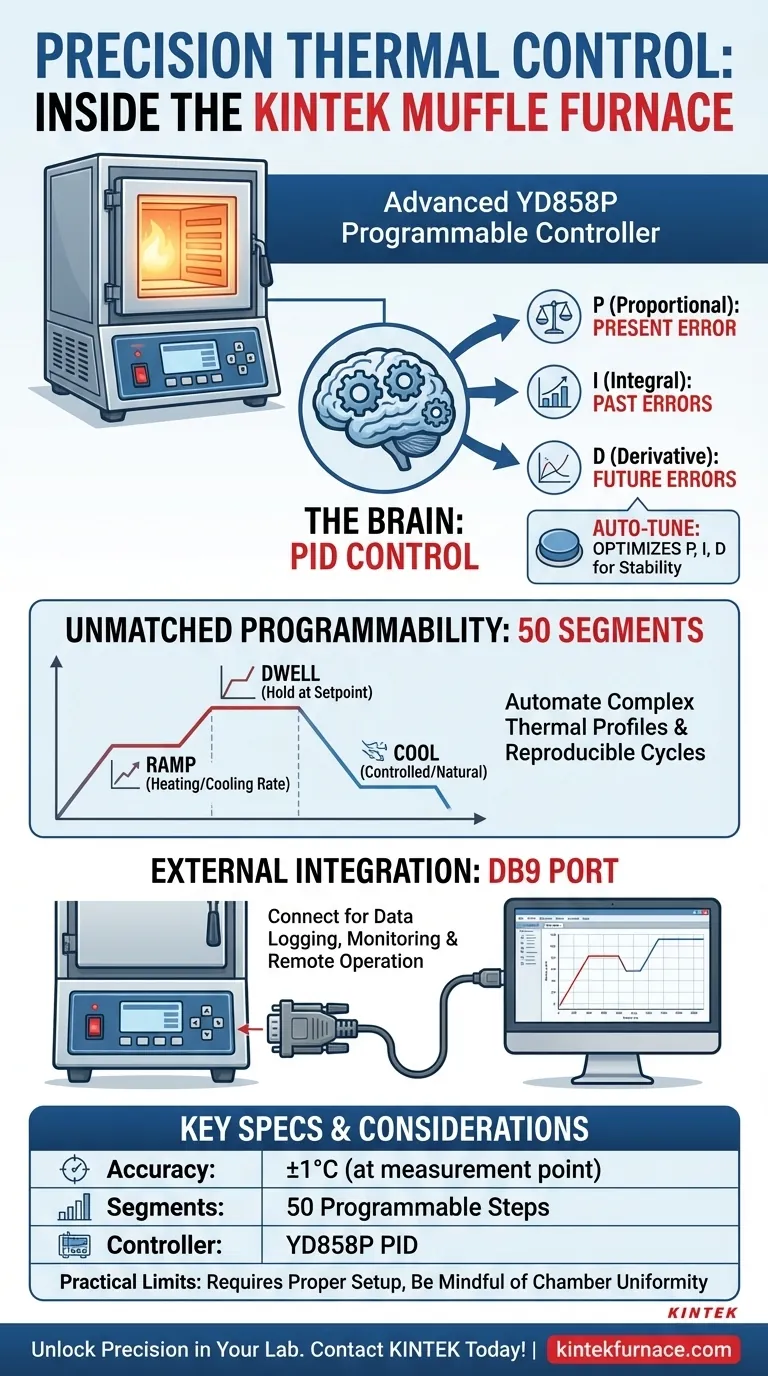

At its core, the muffle furnace utilizes a sophisticated YD858P programmable temperature controller. This system is defined by its use of PID (Proportional-Integral-Derivative) control, an auto-tune function, and the ability to program complex multi-step heating and cooling cycles, ensuring a temperature accuracy of ±1°C.

The furnace's temperature control system is not just a simple thermostat; it is an advanced process controller designed for precision and reproducibility. Its key features—PID logic, programmability, and auto-tuning—give you exacting control over your entire thermal process from start to finish.

Deconstructing the Temperature Control System

To fully understand the furnace's capabilities, we must look at the key components that enable its precise thermal management. Each element plays a distinct role in achieving consistent and reliable results.

The Brain of the System: PID Control

A PID controller is significantly more advanced than a simple on/off thermostat. It continuously calculates an error value—the difference between the desired temperature (setpoint) and the measured temperature—and applies a correction.

It does this by considering three factors:

- Proportional (P): The present error. A larger difference results in a larger response.

- Integral (I): The accumulation of past errors. This eliminates small, steady-state errors that the proportional term alone can't fix.

- Derivative (D): The prediction of future errors based on the current rate of change. This helps prevent overshooting the target temperature.

The included auto-tune function automatically optimizes these P, I, and D values, adapting the controller's response to the specific thermal properties of your furnace and its contents for maximum stability.

Precision and Reproducibility: Programmable Segments

The controller supports 50 programmable segments. This allows you to design and automate complex thermal profiles beyond just heating to a single temperature.

Each segment can be defined as one of three steps:

- Ramping: Increasing or decreasing the temperature at a specific rate (e.g., 10°C per minute).

- Dwelling: Holding the temperature at a constant setpoint for a specific duration.

- Cooling: A controlled or natural cooling period.

This programmability is essential for processes requiring precise, repeatable heating and cooling cycles, ensuring that results are consistent from one run to the next.

External Integration: The DB9 Communication Port

The furnace includes a default DB9 PC communication port. This feature enables you to connect the controller to a computer, which unlocks capabilities for advanced monitoring, data logging, or remote operation of your thermal processes.

Understanding the System's Practical Limits

While the controller is highly capable, its performance is part of a larger system. Understanding the practical trade-offs is key to achieving optimal results.

The Controller and the Heating Elements

The control system manages the power sent to the open coil heating elements. The references note that these elements provide a fast heat-up.

While rapid heating is often desirable, it places a greater demand on the PID controller to anticipate and prevent temperature overshoot. The auto-tune function is critical here for ensuring the system doesn't exceed its target.

Proper Setup is Non-Negotiable

The controller is not a "plug-and-play" device. Before operation, you must set the required working temperature and properly initiate the heating cycle.

Failure to configure the controller correctly can lead to inaccurate results or failed processes, regardless of the system's advanced capabilities. Always confirm that the ammeter and temperature display show normal operation after starting a cycle.

Accuracy vs. Uniformity

The specified accuracy of ±1°C applies to the point where the temperature is measured, typically by a thermocouple. While the design aims for a minimal temperature gradient, you should not assume the temperature is perfectly uniform throughout the entire chamber, especially when heavily loaded.

Making the Right Choice for Your Goal

To get the most out of this system, align its features with your specific application.

- If your primary focus is a simple, stable hold temperature: Rely on the PID control and run the auto-tune function to ensure the furnace holds your setpoint with maximum stability and minimal overshoot.

- If your primary focus is complex, multi-stage processing: Leverage the 50 programmable segments to precisely define every ramp, dwell, and cooling step for highly reproducible results.

- If your primary focus is process validation and data logging: Utilize the DB9 communication port to connect to a PC for real-time monitoring and to create a permanent record of your temperature cycles.

Understanding how this control system works empowers you to move from simply using the furnace to truly mastering your thermal process.

Summary Table:

| Feature | Description |

|---|---|

| Controller Type | YD858P Programmable PID Controller |

| Control Method | Proportional-Integral-Derivative (PID) with Auto-Tune |

| Temperature Accuracy | ±1°C |

| Programmability | 50 Segments for Ramp, Dwell, and Cooling Steps |

| Communication | DB9 PC Port for Data Logging and Remote Operation |

Unlock Precision in Your Lab with KINTEK's Advanced Furnace Solutions

Are you striving for exact temperature control and reproducibility in your thermal processes? KINTEK specializes in high-temperature furnaces tailored for diverse laboratory needs. Leveraging our exceptional R&D and in-house manufacturing, we offer a comprehensive product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—enhanced by deep customization to meet your unique experimental requirements. Our expertise ensures you achieve superior performance and efficiency in applications like material testing, heat treatment, and more.

Ready to elevate your research? Contact us today for a personalized consultation and discover how our solutions can drive your success!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis