At its core, a Chemical Vapor Deposition (CVD) furnace uses a Programmable Logic Controller (PLC) combined with an operator interface as its primary process control system. This rugged industrial computer is responsible for executing the precise, pre-programmed sequences required for material synthesis, from managing gas flow to regulating temperature profiles.

The name "PLC" only tells part of the story. True CVD process control is about an integrated system where the PLC orchestrates temperature, gas delivery, and timing with extreme precision to ensure reproducible, high-quality results.

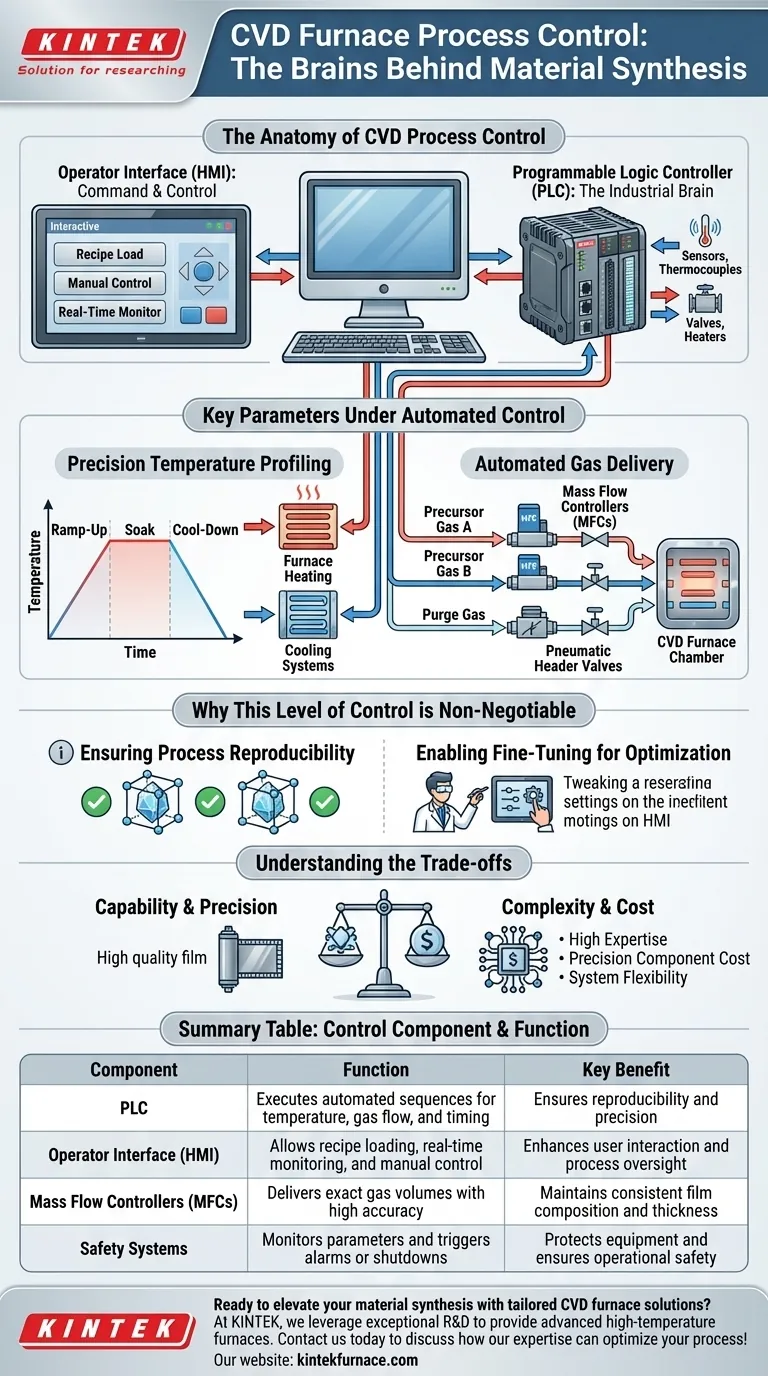

The Anatomy of CVD Process Control

A modern CVD furnace is more than a simple oven; it is a sophisticated synthesis instrument. The control system is its central nervous system, ensuring every variable is managed according to the defined process recipe.

The PLC: The Industrial Brain

A Programmable Logic Controller (PLC) is a hardened computer designed to withstand industrial environments and reliably execute automated tasks. In a CVD furnace, it is the core decision-maker, reading inputs from sensors and activating outputs like valves and heaters.

The Operator Interface: Command and Control

The operator interface, often a touchscreen HMI (Human-Machine Interface), is the user's window into the process. It allows an operator to load recipes, manually control components, monitor process variables in real-time, and view alarms.

Key Parameters Under Automated Control

The PLC's primary function is to provide unwavering control over the critical parameters that govern the CVD reaction.

Precision Temperature Profiling

The PLC manages complex temperature recipes, including controlled ramp-up rates, stable soak times at specific temperatures, and controlled cool-downs. This ensures the chemical reactions occur at the optimal energy state.

Automated Gas Delivery

Precise control of precursor gases is fundamental to CVD. The PLC uses mass flow controllers (MFCs) to deliver exact volumes of different gases. It also controls pneumatic actuators on header valves to switch gas sources and purge lines automatically.

Real-Time Monitoring and Safety

The system constantly monitors variables like temperature, pressure, and gas flow. If any parameter deviates from its setpoint, the PLC can trigger an alarm or initiate a safe shutdown sequence, protecting both the equipment and the product.

Why This Level of Control is Non-Negotiable

The sophistication of this control system is directly linked to the quality and consistency of the final material.

Ensuring Process Reproducibility

Without a PLC automating the sequence, minor variations in timing or flow rates from run to run would lead to inconsistent film thickness, composition, and material properties. Automation eliminates this human variability.

Enabling Fine-Tuning for Optimization

Researchers and process engineers rely on the control system to systematically tweak parameters. This ability to make small, controlled changes is essential for developing new materials and optimizing deposition processes for specific applications.

Understanding the Trade-offs

While advanced control is powerful, it's important to recognize the associated complexities.

Capability vs. Complexity

A highly capable, fully automated system offers incredible process control but also requires significant expertise to program, maintain, and troubleshoot. Simpler systems may be easier to operate but offer less precision.

Cost of Precision Components

Features like high-accuracy mass flow controllers, multi-zone temperature control, and advanced vacuum gauges add significant cost to the furnace. The required level of precision must be justified by the application's demands.

System Flexibility

Custom control systems can be perfectly tailored to a unique process but may create vendor lock-in. Systems built on standard, widely used PLC platforms offer greater long-term flexibility for support and upgrades.

Making the Right Choice for Your Goal

The ideal control system configuration depends entirely on your objective.

- If your primary focus is research and development: Prioritize a system with maximum programming flexibility, comprehensive data logging, and the ability to easily modify gas and temperature parameters.

- If your primary focus is high-volume production: Emphasize robust automation, unwavering reproducibility, detailed alarm management, and strict safety interlocks to ensure consistent output and operator safety.

- If your primary focus is education or foundational studies: A system with a more transparent interface that clearly visualizes the process steps may be more valuable than one with maximum automation.

Ultimately, effective process control is the bridge that turns the theoretical chemistry of a material into a tangible, reliable, and high-performance product.

Summary Table:

| Control Component | Function | Key Benefit |

|---|---|---|

| PLC (Programmable Logic Controller) | Executes automated sequences for temperature, gas flow, and timing | Ensures reproducibility and precision in material synthesis |

| Operator Interface (HMI) | Allows recipe loading, real-time monitoring, and manual control | Enhances user interaction and process oversight |

| Mass Flow Controllers (MFCs) | Delivers exact gas volumes with high accuracy | Maintains consistent film composition and thickness |

| Safety Systems | Monitors parameters and triggers alarms or shutdowns | Protects equipment and ensures operational safety |

Ready to elevate your material synthesis with tailored CVD furnace solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnaces, including CVD/PECVD Systems, Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces. Our deep customization capabilities ensure precise control for your unique experimental needs, whether in research, production, or education. Contact us today to discuss how our expertise can optimize your process and deliver reliable, high-performance results!

Visual Guide

Related Products

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

People Also Ask

- What are the practical applications of gate media prepared by CVD tube furnaces? Unlock Advanced Electronics and More

- What are 2D heterostructures and how are they created using CVD tube furnaces? Unlock Atomic-Scale Material Engineering

- Why is the tube design important in CVD furnaces? Ensure Uniform Deposition for High-Quality Films

- Why are advanced materials and composites important? Unlock Next-Gen Performance in Aerospace, Auto, and More

- What is the process for synthesizing transition metal dichalcogenides (TMDs) using CVD tube furnaces? Master High-Quality Thin Film Growth