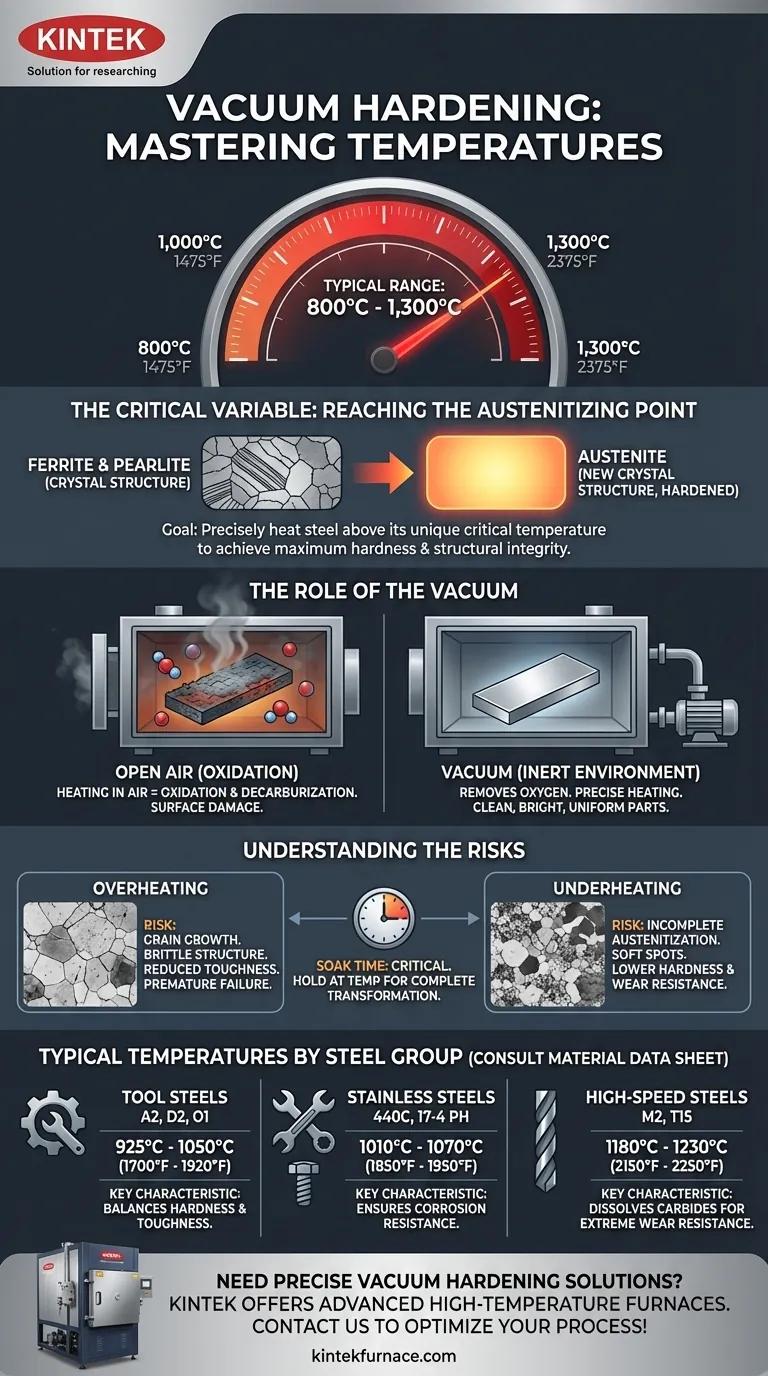

In vacuum hardening, the precise temperature used is dictated entirely by the specific steel alloy being treated, but generally falls within a range of 800°C to 1,300°C (1475°F to 2375°F). While furnaces can reach higher temperatures, the goal is not to achieve maximum heat, but to hit a very specific metallurgical transformation point for the material in question.

The core principle of vacuum hardening is not simply heating metal. It is the precise application of temperature to reach a steel's unique austenitizing point within a controlled, inert environment to achieve maximum hardness and structural integrity without surface contamination.

Why Temperature Is the Critical Variable

The purpose of hardening is to fundamentally change the crystalline structure of steel to make it harder and more wear-resistant. Temperature is the primary tool used to control this transformation.

Reaching the Austenitizing Point

For hardening to occur, steel must be heated above a critical temperature where its crystal structure (typically ferrite and pearlite) transforms into a new structure called austenite. This is known as the austenitizing temperature.

Each steel alloy has a specific, and often narrow, austenitizing temperature range. This target temperature is the single most important factor in the hardening process.

The Role of the Vacuum

Heating steel to these temperatures in open air would cause immediate and severe oxidation (scaling) and decarburization (loss of surface carbon), ruining the component.

The vacuum removes the oxygen and other reactive gases. This allows the part to be heated to its precise austenitizing temperature and then quenched, resulting in a clean, bright, and uniformly hardened part with no surface damage.

Typical Temperatures by Steel Group

While you must always consult the material's data sheet, certain steel families have predictable temperature requirements.

- Tool Steels (e.g., A2, D2, O1): These common steels typically require temperatures between 925°C and 1050°C (1700°F and 1920°F).

- Stainless Steels (e.g., 440C, 17-4 PH): Martensitic stainless steels are hardened in a range of 1010°C to 1070°C (1850°F to 1950°F).

- High-Speed Steels (e.g., M2, T15): These highly alloyed steels demand much higher temperatures, often from 1180°C to 1230°C (2150°F to 2250°F), to dissolve tough carbides into the austenite structure.

Understanding the Trade-offs

Choosing the wrong temperature, even by a small margin, can have significant negative consequences on the final component. This is a process of precision, not brute force.

The Risk of Overheating

Exceeding the recommended austenitizing temperature causes grain growth. Large austenitic grains transform into a coarse, brittle martensitic structure upon quenching. This dramatically reduces the steel's toughness and can lead to premature failure.

The Problem of Underheating

Failing to reach the proper temperature results in incomplete austenitization. Not all of the initial structure transforms, leaving soft spots in the final part. This means the component will not achieve its specified hardness or wear resistance.

Soak Time: The Partner to Temperature

Reaching the target temperature is only half the battle. The component must be held at that temperature—a process called soaking—long enough for the transformation to complete throughout its entire cross-section, from the surface to the core.

Making the Right Choice for Your Material

Your material's data sheet is the ultimate authority. However, understanding the goal behind the numbers will help you collaborate effectively with your heat treatment provider.

- If your primary focus is hardening common tool steels (e.g., A2, D2): Expect austenitizing temperatures in the 950°C to 1050°C range to achieve an optimal balance of hardness and toughness.

- If your primary focus is maximizing wear resistance with high-speed steels (e.g., M2): Be prepared for higher temperatures, often exceeding 1200°C, required to dissolve the complex carbides that provide extreme hardness.

- If your primary focus is corrosion resistance in stainless steels: Target the specific austenitizing temperature that ensures both hardness and the proper solution of chromium for rust prevention.

Ultimately, mastering the temperature in vacuum hardening allows you to precisely engineer the final properties of your component.

Summary Table:

| Steel Group | Typical Temperature Range (°C) | Typical Temperature Range (°F) | Key Characteristics |

|---|---|---|---|

| Tool Steels | 925°C - 1050°C | 1700°F - 1920°F | Common for A2, D2, O1; balances hardness and toughness |

| Stainless Steels | 1010°C - 1070°C | 1850°F - 1950°F | Martensitic types like 440C, 17-4 PH; ensures corrosion resistance |

| High-Speed Steels | 1180°C - 1230°C | 2150°F - 2250°F | Alloys like M2, T15; dissolves carbides for extreme wear resistance |

Need precise vacuum hardening solutions for your steel alloys? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnaces, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental requirements, delivering maximum hardness and structural integrity without surface contamination. Contact us today to optimize your heat treatment processes!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- How is vacuum heat treatment applied to elastic alloys? Unlock Peak Performance in Aerospace and Medical Devices

- What role does vacuum radiation play in CAP capping? Optimize Ingot Integrity and Material Yield

- How are vacuum furnaces utilized in electronic component manufacturing? Unlock High-Purity Production for Superior Electronics

- Why is a high-temperature annealing furnace required for HP40Nb reformer tubes? Ensure Crack-Free Repair Welding

- What industries utilize vacuum technology in thermal processing? Unlock High-Performance Material Production

- What are the main types of vacuum furnace chambers and their temperature ranges? Find the Perfect Fit for Your Lab

- What is the primary use of a vacuum hydrogen dual-purpose furnace? Essential for Diamond Synthesis and High-Performance Sintering

- What role does a vacuum drying oven play in graphene cathode manufacturing? Achieve High-Performance Battery Components