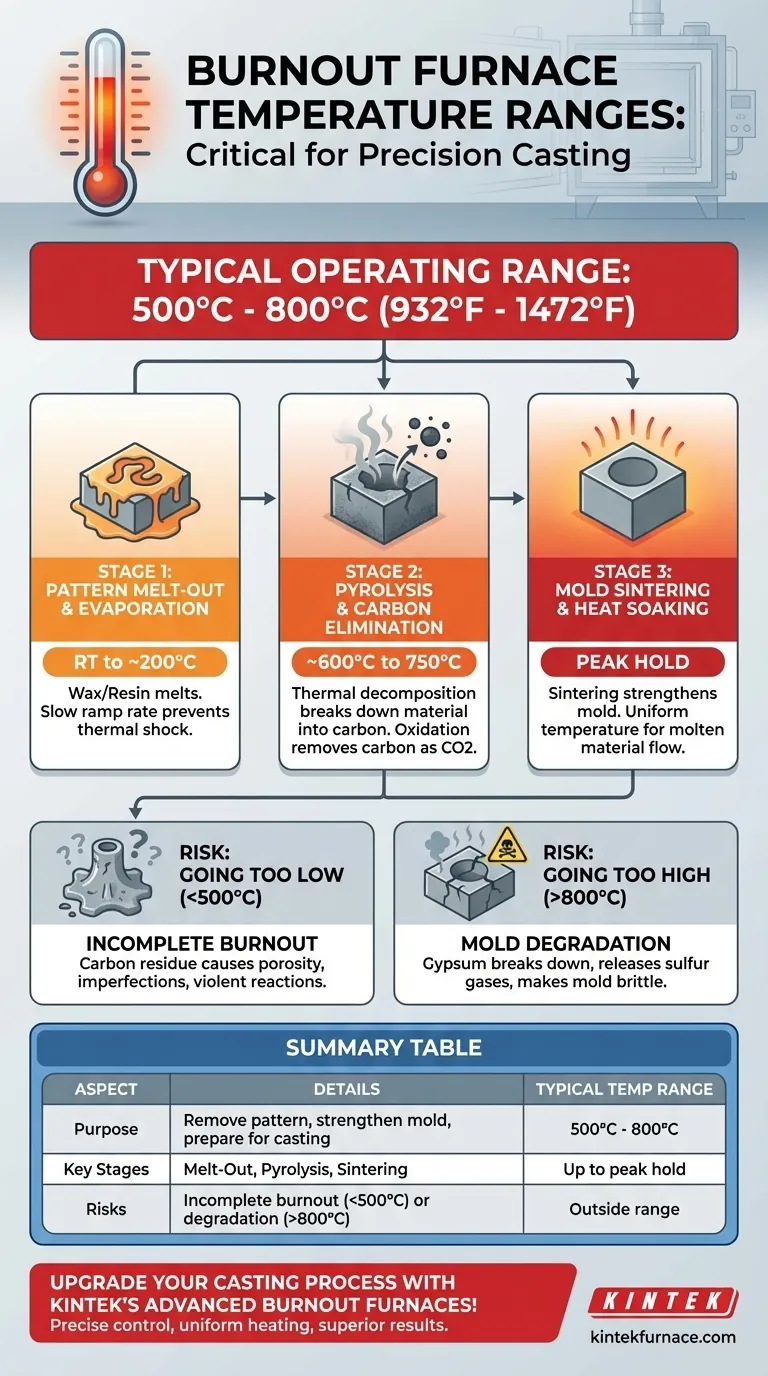

In practice, a burnout furnace typically operates within a moderate temperature range of 500°C to 800°C (932°F to 1472°F). This specific range is a critical balance, designed to completely eliminate the original pattern material, like wax or resin, without causing the investment mold itself to crack or degrade.

The goal of a burnout cycle is not simply to heat a mold, but to execute a precise thermal process. Success depends on completely removing the pattern while simultaneously strengthening the mold and preparing it for the introduction of molten material.

The Purpose of a Burnout Cycle

A burnout furnace's primary job is to create a perfect, hollow cavity inside an investment mold. This process happens in distinct thermal stages, each critical for a successful casting.

Stage 1: Pattern Melt-Out and Evaporation

At the lower end of the temperature range, typically from room temperature up to around 200°C, the wax or resin pattern will melt. A slow increase in temperature, known as the ramp rate, is crucial here to allow the material to liquefy and drain without expanding rapidly and causing thermal shock, which can crack the mold.

Stage 2: Pyrolysis and Carbon Elimination

As the temperature rises toward 600°C to 750°C, the core of the burnout process occurs. Any residual pattern material undergoes pyrolysis—a thermal decomposition in a low-oxygen environment. This breaks down the complex molecules into elemental carbon (soot), which is then oxidized and removed from the mold as carbon dioxide gas, leaving a clean cavity.

Stage 3: Mold Sintering and Heat Soaking

At the peak temperature, often held for several hours, two things happen. The investment material is sintered, increasing its strength and thermal stability. The mold is also "heat soaked," ensuring it is at a uniform, optimal temperature for receiving the molten metal or other casting material, which promotes proper flow and detail capture.

Understanding the Critical Temperature Range

The 500°C to 800°C window is not arbitrary. Deviating from it introduces significant risks to the final product.

The Risk of Going Too Low

Operating below 500°C, or not holding the peak temperature long enough, risks incomplete burnout. If carbon residue remains inside the mold cavity, it can create porosity in the final casting, lead to surface imperfections, or even cause a violent reaction when the molten metal is introduced.

The Risk of Going Too High

Exceeding the recommended temperature for your investment material can be catastrophic. Most common gypsum-bonded investments begin to break down above 800°C, releasing sulfur gases that contaminate metal alloys and causing the mold to become brittle and prone to failure.

Burnout vs. Ceramic Firing

It is important to distinguish burnout from ceramic firing. While a ceramic furnace may operate in a similar range of 600°C to 1,000°C, its purpose is different. Ceramic firing is designed to vitrify or sinter the ceramic body itself, fundamentally changing its structure, whereas a burnout furnace's goal is simply to empty and prepare a mold.

Setting Your Burnout Cycle for Success

The ideal temperature profile depends entirely on your specific materials and the desired outcome.

- If your primary focus is traditional wax casting: A peak temperature around 700-750°C is a standard, safe target for most gypsum-based investment materials.

- If your primary focus is casting 3D-printed resins: You must follow the resin manufacturer's burnout schedule, which often requires a slower initial ramp and a longer hold at peak temperature to ensure complete elimination.

- If your primary focus is casting high-temperature alloys: You will need a specialized phosphate-bonded investment and will operate at the upper end of the burnout range, closer to 800°C, as specified by the material manufacturer.

Mastering the burnout process is about controlling heat over time to prepare a perfect negative space for your final casting.

Summary Table:

| Aspect | Details |

|---|---|

| Typical Temperature Range | 500°C to 800°C (932°F to 1472°F) |

| Purpose | Remove pattern material, strengthen mold, and prepare for casting |

| Key Stages | Pattern Melt-Out (up to 200°C), Pyrolysis (600°C-750°C), Mold Sintering (peak hold) |

| Risks of Deviation | Incomplete burnout (below 500°C) or mold degradation (above 800°C) |

Upgrade Your Casting Process with KINTEK's Advanced Burnout Furnaces!

Struggling with incomplete burnout or mold failures? KINTEK specializes in high-temperature furnace solutions tailored for laboratories in jewelry making, metal casting, and research. Our burnout furnaces offer precise temperature control and uniform heating to ensure flawless mold preparation and superior casting results.

Leveraging exceptional R&D and in-house manufacturing, we provide Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization to meet your unique experimental needs. Whether you're working with wax, 3D-printed resins, or high-temperature alloys, our furnaces deliver reliability and efficiency.

Contact us today to discuss how our solutions can enhance your lab's productivity and achieve perfect castings every time!

Visual Guide

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the significance of temperature control precision in high-temperature furnaces for carbon-doped titanium dioxide?

- What is the significance of using a muffle furnace to determine the ash content of biochar? Master Material Performance

- Why is calcination essential for NaFePO4 phase formation? Engineering High-Performance Sodium Iron Phosphate

- What is the significance of the thermal environment in calcination? Achieve Pure Ceramic Phases with KINTEK

- Why is immediate water-quenching required after thermal simulation? Preserve (CoCrNi)94Al3Ti3 Alloy Microstructure