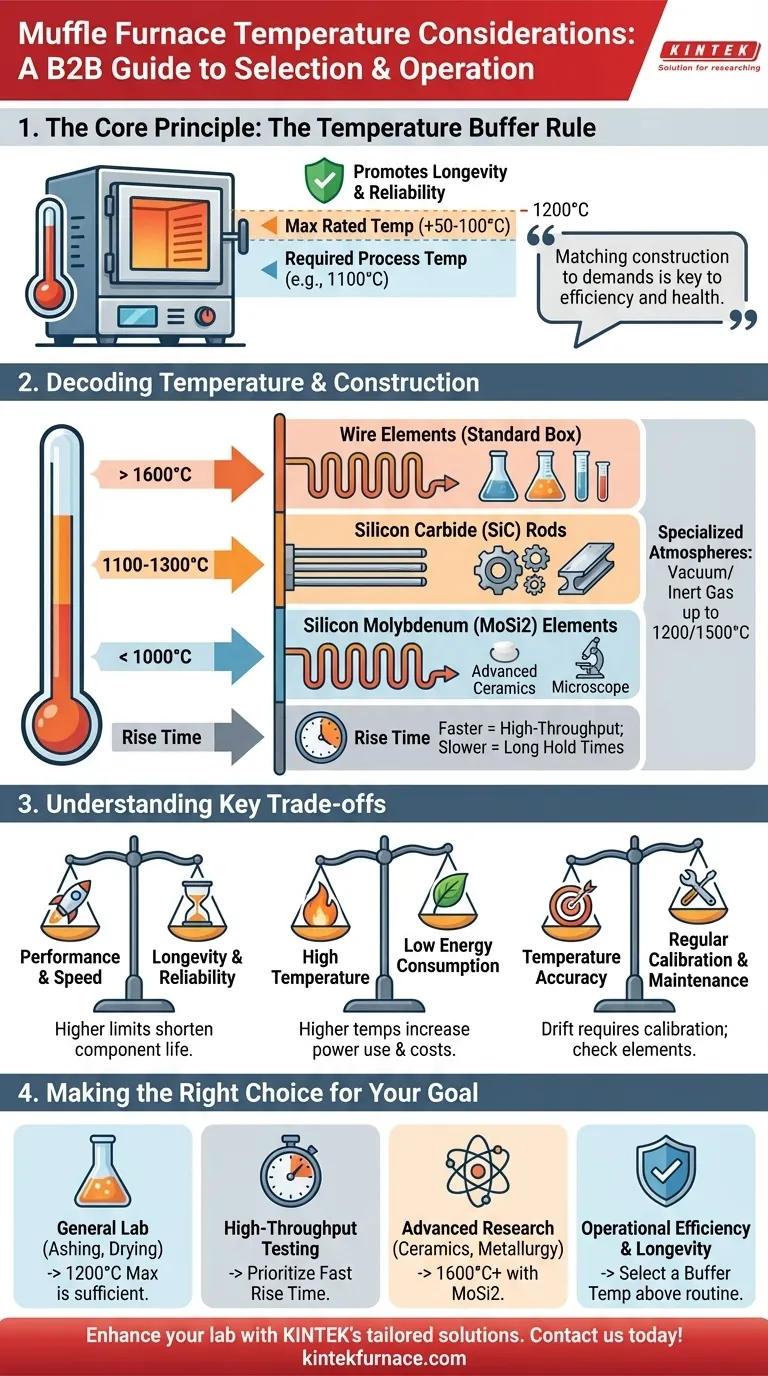

When selecting or operating a muffle furnace, the most important temperature considerations are its maximum operating temperature, its typical operating range, and its rise time. Choosing a furnace with a maximum temperature slightly above your required process temperature is a critical best practice, as this prevents constant operation at its absolute limit, which extends the life of the heating elements and insulation.

The core decision is not just about reaching a specific temperature, but about matching the furnace's material construction to your application's demands. Understanding this relationship is the key to ensuring operational efficiency, process reliability, and long-term equipment health.

Decoding Temperature Specifications

The temperature rating of a muffle furnace is its single most important specification. It dictates what the furnace is made of, what it can be used for, and how much it will cost to run.

Standard Operating Ranges

Most standard laboratory muffle furnaces operate up to temperatures between 1000°C and 1200°C. This range is suitable for a wide variety of common applications like ashing, heat-treating metals, and materials testing.

Industrial and specialized models can achieve much higher temperatures, with some high-temperature units reaching 1600°C to 1800°C for more demanding processes.

The Importance of Maximum Temperature

A furnace's maximum rated temperature is a capability, not a recommended cruising speed. Continuously running a furnace at its absolute limit places extreme stress on its heating elements and insulation.

For optimal longevity and performance, a good rule of thumb is to select a furnace with a maximum temperature at least 50°C to 100°C higher than your highest routine operating temperature. This provides a buffer that significantly prolongs equipment life.

Understanding Rise Time

Rise time is the duration it takes for the furnace to heat from ambient temperature to its maximum temperature. This metric is a key indicator of performance.

A faster rise time is crucial for high-throughput environments where minimizing cycle time is a priority. For applications where the furnace will be held at temperature for long periods, rise time may be a less critical factor.

How Temperature Dictates Furnace Construction

A furnace's temperature capability is a direct result of its internal components, primarily its heating elements. Different materials are required to reliably produce and withstand different heat levels.

Below 1000°C (Standard Box Furnaces)

These furnaces typically use robust wire heating elements and are designed for general-purpose applications. They represent the most common and cost-effective category of muffle furnaces.

1100°C to 1300°C (Silicon Carbide Elements)

To reliably operate in this higher range, furnaces often employ silicon carbide (SiC) rods as heating elements. These are more durable at elevated temperatures and are suited for processes requiring more intense heat.

Above 1600°C (Silicon Molybdenum Elements)

Reaching temperatures for advanced ceramics and metallurgical research requires specialized equipment. These furnaces use silicon molybdenum (MoSi2) heating elements, which can withstand extreme thermal cycling and sustain very high temperatures.

Specialized Atmospheres (Vacuum & Inert Gas)

Some processes require heating in a controlled atmosphere to prevent oxidation. Vacuum or inert gas muffle furnaces are available with specific temperature ratings, often up to 1200°C or 1500°C, and include the necessary ports for managing the internal atmosphere.

Understanding the Trade-offs

Selecting a furnace involves balancing competing priorities. Being aware of the inherent trade-offs is essential for making an informed decision.

Performance vs. Longevity

Pushing a furnace to its maximum temperature and fastest rise time will shorten the lifespan of its components. Operating within a more conservative range ensures greater reliability and less downtime for maintenance.

Temperature vs. Energy Consumption

Higher temperatures require exponentially more energy. A furnace capable of 1800°C will have significantly higher power consumption than a 1200°C model, leading to higher operational costs. Evaluating energy consumption is critical for budgeting and sustainability goals.

Accuracy vs. Maintenance

A furnace's temperature accuracy can drift over time. Maintaining the validity of your results requires regular temperature calibration. This is a critical maintenance step, along with inspecting heating elements for wear and checking insulation for damage, which can cause heat loss and inefficiency.

Making the Right Choice for Your Goal

Use your primary application to guide your decision on temperature specifications.

- If your primary focus is general laboratory work (e.g., ashing, drying): A standard furnace with a maximum temperature of 1200°C is typically sufficient and cost-effective.

- If your primary focus is high-throughput testing: Prioritize a model with a fast rise time to minimize the duration of each cycle.

- If your primary focus is advanced materials research (e.g., ceramics, metallurgy): You will need a high-temperature model (1600°C+) with specialized heating elements like silicon molybdenum.

- If your primary focus is operational efficiency and longevity: Select a furnace with a maximum temperature comfortably above your normal working temperature to avoid running it at its absolute limit.

By understanding the relationship between temperature, construction, and operational costs, you can select a muffle furnace that serves as a reliable and efficient tool for years to come.

Summary Table:

| Temperature Range | Heating Element | Common Applications | Key Considerations |

|---|---|---|---|

| Below 1000°C | Wire elements | General lab work (e.g., ashing, drying) | Cost-effective, standard use |

| 1100°C to 1300°C | Silicon carbide (SiC) rods | Heat-treating, materials testing | Durable for higher heat |

| Above 1600°C | Silicon molybdenum (MoSi2) | Advanced ceramics, metallurgy | High-temperature, specialized |

| Up to 1200°C or 1500°C | Varies (for vacuum/inert gas) | Controlled atmosphere processes | Prevents oxidation, specific ports |

Ready to enhance your lab's capabilities with a tailored muffle furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, boosting efficiency and reliability. Contact us today to discuss how we can support your specific needs!

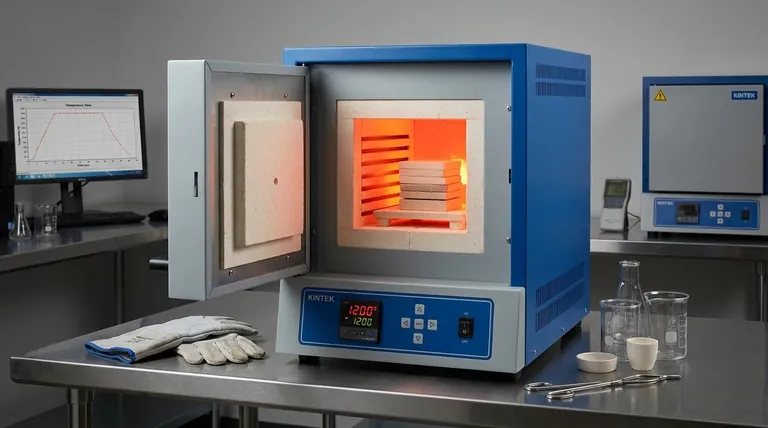

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation