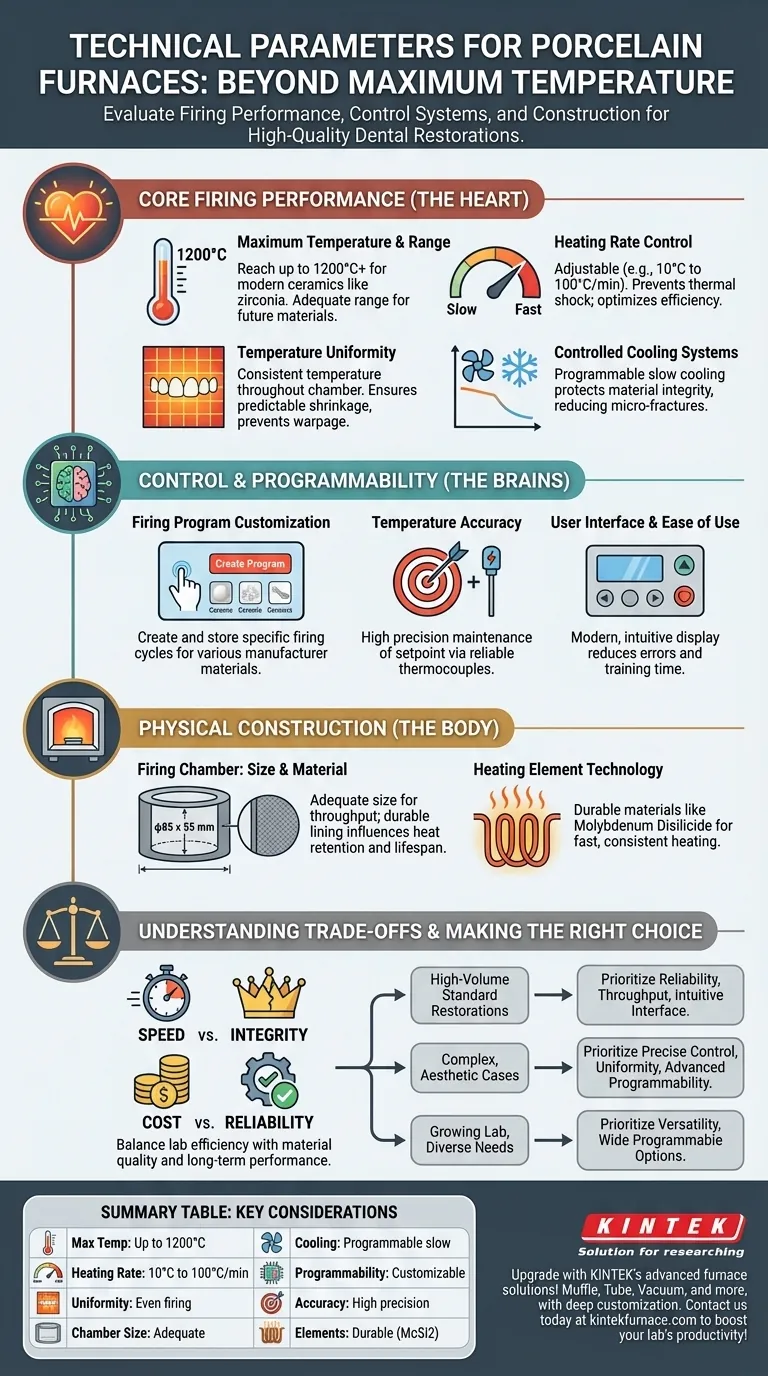

To properly evaluate a porcelain furnace, you must look beyond the maximum temperature and assess a combination of technical parameters. The most critical specifications involve its firing performance, including heating rate and temperature uniformity; its control system, such as programmability and accuracy; and its physical construction, which includes the chamber material and heating elements. These factors collectively determine the furnace's ability to produce consistent, high-quality dental restorations.

The core challenge is not simply buying a furnace that gets hot, but selecting one that provides the precise thermal control required by modern dental materials. True success lies in matching the furnace's programmability and its heating and cooling capabilities to the specific demands of the ceramics you use most often.

Core Firing Performance: The Heart of the Furnace

The ultimate quality of a restoration is a direct result of how well the furnace manages the firing cycle. This is the most critical area of evaluation.

Maximum Temperature and Range

The furnace must be able to reach the temperatures required for the materials you work with. Modern ceramics, especially certain types of zirconia, may require temperatures up to or exceeding 1200°C.

An adequate temperature range ensures you are not limited in your choice of materials now or in the future.

Heating Rate Control

The speed at which the furnace reaches its target temperature is a critical variable. A furnace with a wide, controllable heating rate (e.g., 10°C to 100°C per minute) offers immense flexibility.

Slower rates are crucial for preventing thermal shock and cracking in large or complex restorations, while faster rates can improve lab efficiency for smaller, standard jobs.

Temperature Uniformity

This refers to the consistency of temperature throughout the entire firing chamber. Poor uniformity can cause one part of a restoration, like a large bridge, to be fired differently than another.

Look for furnaces that guarantee a high degree of temperature uniformity across the firing tray. This is essential for predictable shrinkage and preventing warpage or distortion.

Controlled Cooling Systems

The cooling phase is just as important as the heating phase. Uncontrolled, rapid cooling can introduce stress into the ceramic, leading to micro-fractures that compromise the final restoration.

Advanced furnaces feature programmable, slow-cooling systems that protect the material's integrity, which is especially vital for all-ceramic and zirconia restorations.

Control and Programmability: The Brains of the Operation

A furnace's performance is only as good as its control system. This is what allows a technician to translate material science into a predictable, repeatable process.

Firing Program Customization

Materials from different manufacturers have unique firing parameters. A furnace with fully programmable cycles is a necessity, not a luxury.

This allows you to create, store, and modify programs based on the specific requirements of any given porcelain or ceramic, ensuring optimal results for every case.

Temperature Accuracy and Measurement

There is a difference between the temperature you set and the actual temperature inside the chamber. Temperature control accuracy defines how closely the furnace maintains the setpoint.

A high-quality temperature measuring element (thermocouple) and a sophisticated controller are key to minimizing this deviation and achieving consistent outcomes.

User Interface and Ease of Use

A complex interface can lead to errors and increase training time. A modern, intuitive control panel with a clear digital display simplifies programming and reduces the risk of mistakes.

The ability to easily select pre-set programs or create custom ones is a hallmark of a well-designed furnace.

Physical Construction and Reliability

The physical build of the furnace dictates its longevity, maintenance needs, and capacity.

Firing Chamber: Material and Size

The chamber must be large enough to accommodate the size and volume of your typical casework. Consider the internal dimensions (e.g., φ85 x 55 mm) to assess throughput capacity.

The chamber's internal lining material also influences heat retention, purity of the firing environment, and long-term durability.

Heating Element Technology

The heating elements are the engine of the furnace. Molybdenum disilicide is a common material for high-performance elements due to its durability and ability to heat quickly and consistently.

The quality and design of these elements directly impact the furnace's lifespan and its ability to maintain performance over thousands of cycles.

Understanding the Trade-offs

Choosing a furnace involves balancing competing priorities. Objectivity here is key to making a sound investment.

Advanced Features vs. Simplicity

Some furnaces offer advanced features like infrared temperature sensors or specialized vacuum systems. These can provide superior control for highly aesthetic or complex cases.

However, a lab focused on standard PFM or monolithic zirconia crowns may not need these features, and could instead prioritize a simpler, more robust workhorse model.

Speed vs. Material Integrity

While a fast heating rate can increase lab throughput, it also increases the risk of thermal shock, especially with thick restorations.

The ideal furnace is not just fast; it is one that gives you precise control over the rate, allowing you to choose speed when appropriate and caution when necessary.

Initial Cost vs. Long-Term Reliability

A lower-priced furnace might be tempting, but it can be more expensive in the long run. Inconsistent firing, frequent downtime, and high maintenance costs quickly erase initial savings.

Investing in a furnace known for its reliability and backed by strong manufacturer support provides a better return through fewer remakes and more predictable workflows.

Making the Right Choice for Your Restorations

Your final decision should be guided by the type of work your lab performs most often.

- If your primary focus is high-volume standard restorations: Prioritize reliability, chamber size for throughput, and an intuitive interface with easily accessible pre-set programs.

- If your primary focus is complex, aesthetic cases (e.g., large-span bridges, zirconia): Prioritize precise control over heating and cooling rates, exceptional temperature uniformity, and advanced programmability.

- If your primary focus is a growing lab with diverse needs: Prioritize a versatile furnace with a wide range of programmable options to accommodate both current and future materials and techniques.

A thorough evaluation of these parameters ensures your investment results in a foundation for predictable, high-quality clinical outcomes.

Summary Table:

| Parameter | Key Considerations |

|---|---|

| Maximum Temperature | Must reach up to 1200°C for modern ceramics like zirconia |

| Heating Rate Control | Adjustable from 10°C to 100°C/min to prevent thermal shock |

| Temperature Uniformity | Ensures even firing to avoid warpage and distortion |

| Cooling Systems | Programmable slow cooling to reduce stress and micro-fractures |

| Programmability | Customizable firing cycles for different materials |

| Temperature Accuracy | High-precision control with reliable thermocouples |

| Chamber Size | Adequate dimensions (e.g., φ85 x 55 mm) for case throughput |

| Heating Elements | Durable materials like molybdenum disilicide for longevity |

Upgrade your dental lab with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems tailored for precise thermal control. Our deep customization capabilities ensure your porcelain furnace meets unique experimental needs, enhancing restoration quality and lab efficiency. Contact us today to discuss how we can support your specific requirements and boost your productivity!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures