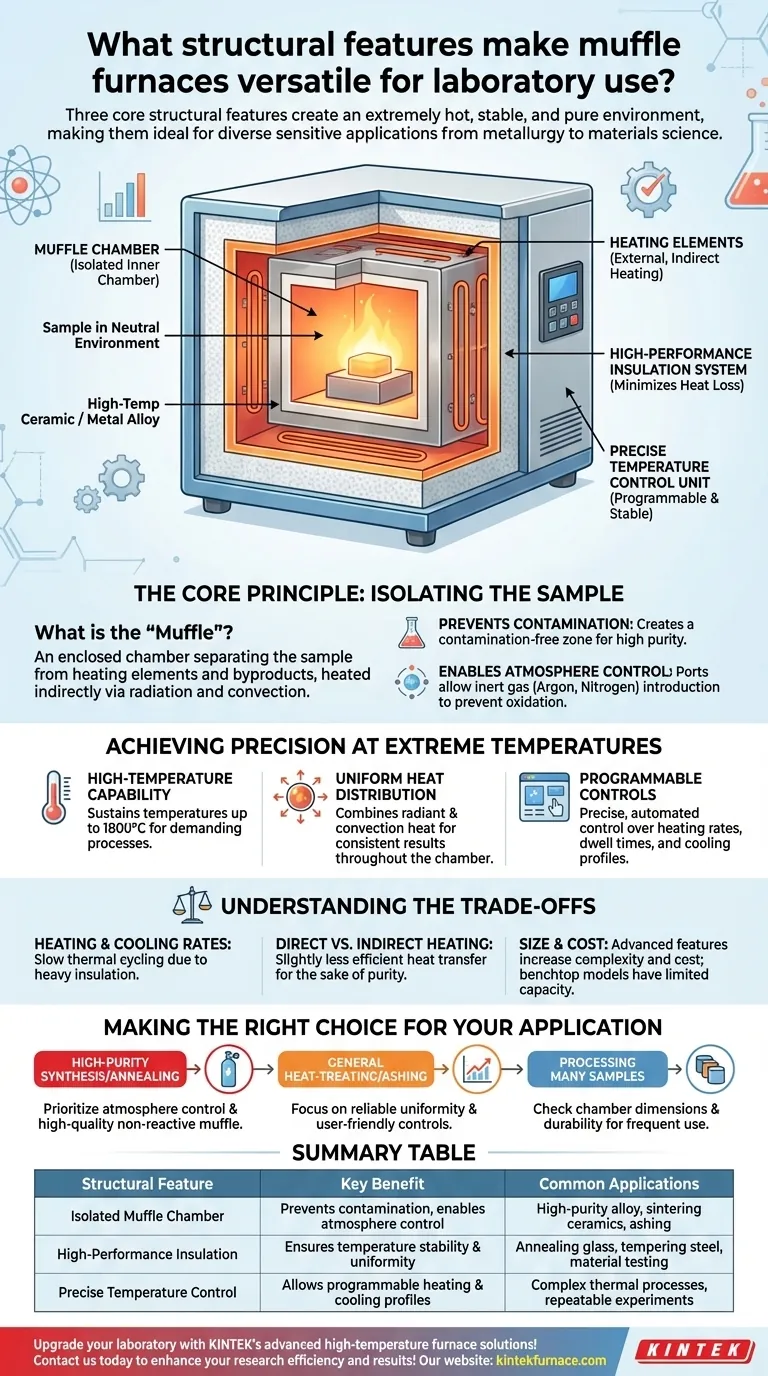

At its core, a muffle furnace's versatility comes from three structural features: an isolated inner chamber called a muffle, a high-performance insulation system, and a precise temperature control unit. This combination allows it to create an extremely hot, stable, and pure environment, making it suitable for a vast range of sensitive laboratory applications from metallurgy to materials science.

The central challenge in many high-temperature processes is preventing the material being heated from reacting with the heat source itself. A muffle furnace solves this by physically separating the sample in a neutral chamber, giving the user complete control over the thermal environment.

The Core Principle: Isolating the Sample

The defining feature of this furnace is the "muffle" itself. Understanding this component is key to understanding the furnace's primary function.

What is the "Muffle"?

A muffle is an enclosed chamber, typically made of high-temperature ceramic or a special metal alloy. It contains the material being processed.

Crucially, the heating elements are located outside of this chamber. This means the sample is heated indirectly through radiation and convection, never coming into direct contact with the electrical elements or any combustion byproducts.

Preventing Contamination

This separation is the furnace's most significant advantage. It creates a contamination-free environment, essential for processes where purity is paramount.

Applications like producing high-purity alloys, sintering sensitive ceramics, or ashing samples for chemical analysis depend on this feature to prevent unwanted reactions or impurities from altering the results.

Enabling Atmosphere Control

The sealed nature of the muffle chamber makes it ideal for controlling the internal atmosphere.

Many models include ports that allow users to purge the air and introduce an inert gas like argon or nitrogen. This prevents oxidation, a critical requirement when working with reactive materials such as titanium or superalloys.

Achieving Precision at Extreme Temperatures

Versatility requires not just high heat, but controlled heat. Muffle furnaces are designed for exceptional stability and uniformity.

High-Temperature Capability

Muffle furnaces are engineered to reach and sustain high temperatures, often ranging from 1000°C to 1800°C (1832°F to 3272°F).

This capability makes them suitable for demanding processes like tempering steel, annealing glass, or sintering advanced materials that require significant thermal energy.

Uniform Heat Distribution

The design combines radiant and convection heat transfer to ensure the temperature is consistent throughout the entire chamber.

This temperature uniformity is vital for getting repeatable results and ensuring that an entire batch or a large single component is treated evenly. Inconsistent heating can lead to failed experiments and flawed materials.

Programmable Controls

Modern muffle furnaces feature advanced digital controllers, thermostats, and timers. These systems allow for precise, automated control over heating rates, dwell times, and cooling profiles.

This level of control is essential for complex, multi-stage thermal processes and ensures that experiments can be replicated with high fidelity.

Understanding the Trade-offs

While highly versatile, the design of a muffle furnace presents certain operational trade-offs that are important to recognize.

Heating and Cooling Rates

The same heavy-duty insulation that makes muffle furnaces so efficient also means they retain heat for a long time. They generally heat up and, more significantly, cool down slowly.

This can be a limitation in high-throughput environments where rapid thermal cycling is required. Other furnace types may be better suited for applications needing quick cooldowns.

Direct vs. Indirect Heating

Because the heating is indirect, heat transfer can be slightly less efficient than in a furnace where the elements are exposed directly to the workload.

However, this is the necessary price for the purity and contamination-free environment that is the muffle furnace's primary purpose.

Size and Cost

Features like advanced atmospheric controls, higher temperature ratings, and larger chamber volumes increase the unit's complexity and cost. Benchtop models offer a compact footprint for labs but have limited capacity.

Making the Right Choice for Your Application

Selecting the right furnace depends entirely on your specific experimental goals.

- If your primary focus is high-purity synthesis or annealing: Prioritize a furnace with excellent atmosphere control capabilities and a high-quality, non-reactive ceramic muffle.

- If your primary focus is general heat-treating or ashing: A model with reliable temperature uniformity and user-friendly programmable controls is your most critical need.

- If your primary focus is processing many samples: Pay close attention to the internal chamber dimensions and the durability of the insulation and door seals to withstand frequent use.

Ultimately, the structural design of a muffle furnace makes it a reliable and precise tool for creating highly controlled thermal environments.

Summary Table:

| Structural Feature | Key Benefit | Common Applications |

|---|---|---|

| Isolated Muffle Chamber | Prevents contamination, enables atmosphere control | High-purity alloy production, sintering ceramics, ashing samples |

| High-Performance Insulation | Ensures temperature stability and uniformity | Annealing glass, tempering steel, material testing |

| Precise Temperature Control Unit | Allows programmable heating and cooling profiles | Complex thermal processes, repeatable experiments |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable muffle furnaces, tube furnaces, and more, all customizable to meet your unique experimental needs. Contact us today to discuss how our precision heating systems can enhance your research efficiency and results!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing