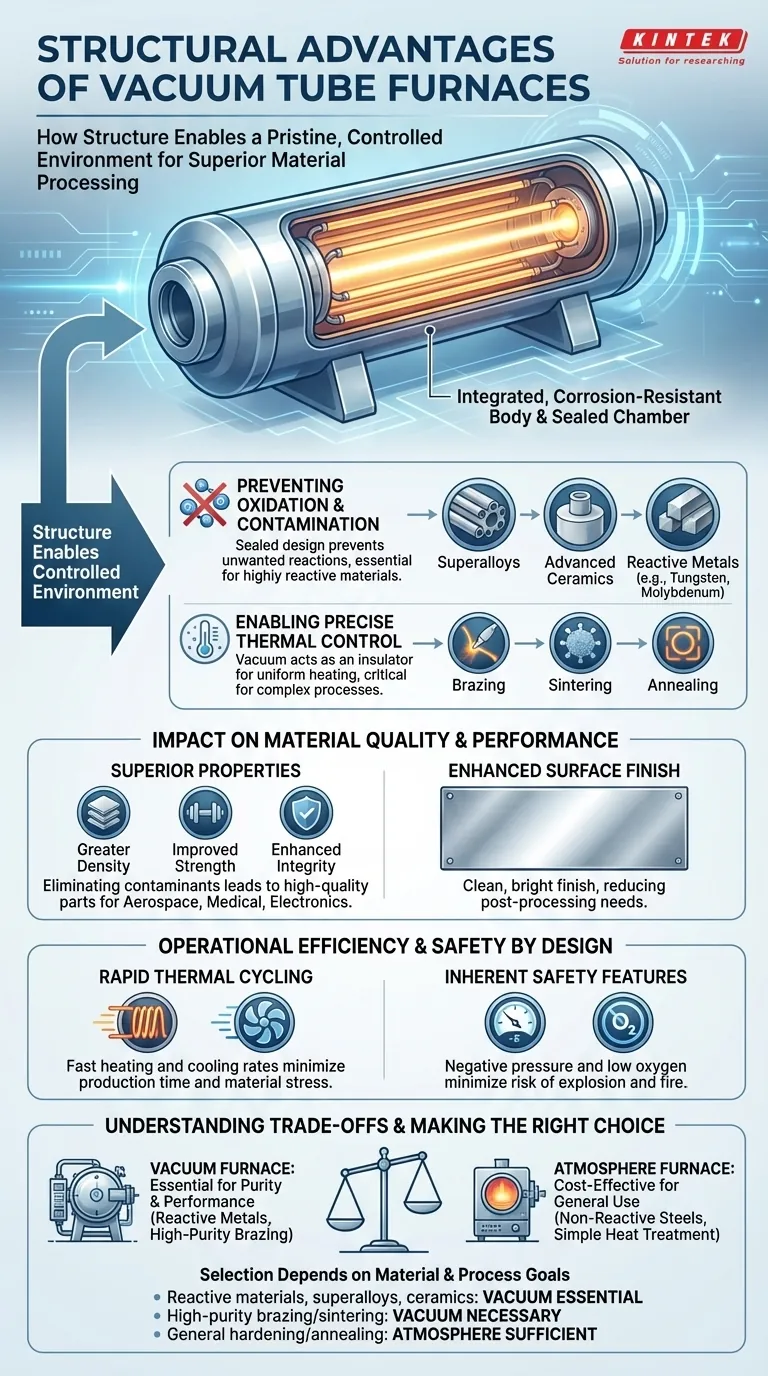

Structurally, a vacuum tube furnace is defined by its compact, integrated body built from high-quality, corrosion-resistant materials. These design choices create a sealed, durable system that is lightweight, resistant to vibration, and engineered for a long service life with minimal contamination.

The core advantage of a vacuum furnace's structure is not its physical form, but its function: to create and maintain a pristine, controlled vacuum. This environment is what enables superior material processing by eliminating atmospheric contamination and enabling precise thermal control.

How Structure Enables a Controlled Environment

The primary function of the furnace's physical construction is to facilitate a stable, air-free processing chamber. This unique environment is the source of its key advantages.

Preventing Oxidation and Contamination

The sealed, integrated body allows for the complete removal of air. Operating in this vacuum prevents unwanted chemical reactions, such as oxidation, that would otherwise degrade the workpiece at high temperatures.

This makes the furnace essential for processing highly reactive or high-performance materials like superalloys, advanced ceramics, and reactive metals such as tungsten and molybdenum.

Enabling Precise Thermal Control

The vacuum environment itself acts as a superb insulator, which, combined with advanced heating elements, allows for extremely precise and uniform temperature control.

This precision is critical for complex processes like brazing, sintering, and annealing, where even minor temperature deviations can compromise the final product's integrity.

The Impact on Material Quality and Performance

The controlled environment created by the furnace's structure directly translates to higher-quality end products with superior physical characteristics.

Superior Material Properties

By eliminating contaminants and ensuring uniform heating, vacuum processing leads to finished parts with greater density, improved strength, and enhanced structural integrity. This is a non-negotiable requirement for components used in aerospace, medical, and advanced electronics.

Enhanced Surface Finish

Without the risk of oxidation, materials exit the furnace with a clean, bright surface finish. This often reduces or eliminates the need for post-processing steps like chemical cleaning or polishing, saving time and resources.

Operational Efficiency and Safety by Design

The furnace's structure is also optimized for production efficiency and operator safety, setting it apart from conventional atmosphere-based furnaces.

Rapid Thermal Cycling

Many vacuum furnaces are engineered for rapid heating rates to minimize production time. Crucially, they also incorporate fast cooling capabilities, which can reduce internal stress and prevent deformation in the material.

Inherent Safety Features

Operating at negative pressure inherently eliminates the risk of explosion that can exist with positive-pressure systems.

Furthermore, the extremely low oxygen content within the vacuum chamber minimizes the risk of fire, making it a fundamentally safer technology compared to many conventional heating furnaces.

Understanding the Trade-offs

While powerful, the specialized nature of a vacuum furnace introduces specific considerations that must be weighed against its benefits.

Not a Universal Solution

These furnaces are purpose-built for processes where atmospheric contamination is a critical failure point. For simple heat treatments on common materials that are not sensitive to oxidation, a less complex and less expensive atmosphere furnace may be more appropriate.

Process Cycle Time

While heating and cooling rates are fast, achieving a deep vacuum can add time to the beginning of each cycle. This "pump-down" time must be factored into overall production planning, especially for high-throughput applications.

Maintenance Complexity

The systems required to create and maintain a high vacuum, including pumps, seals, and gauges, require specialized maintenance. The integrity of the furnace's seals and chamber is paramount and demands rigorous upkeep.

Making the Right Choice for Your Application

Selecting the right furnace depends entirely on your material requirements and process goals.

- If your primary focus is processing reactive metals, superalloys, or advanced ceramics: A vacuum furnace is essential to prevent contamination and achieve the required material properties.

- If your primary focus is high-purity brazing or sintering: The clean, controlled environment of a vacuum furnace is necessary to ensure strong, void-free joints and part consolidation.

- If your primary focus is general-purpose hardening or annealing of non-reactive steels: A conventional atmosphere furnace is often a more cost-effective and operationally simpler solution.

Ultimately, choosing a vacuum furnace is a strategic decision to prioritize material purity and performance above all else.

Summary Table:

| Advantage | Description |

|---|---|

| Prevents Oxidation | Sealed design removes air, eliminating contamination for reactive materials like superalloys and ceramics. |

| Enables Precise Thermal Control | Vacuum environment acts as an insulator, allowing uniform heating for processes like brazing and annealing. |

| Improves Material Quality | Results in higher density, strength, and clean surface finishes, reducing post-processing needs. |

| Enhances Safety | Negative pressure reduces explosion and fire risks compared to conventional furnaces. |

| Supports Rapid Cycling | Fast heating and cooling rates minimize production time and material stress. |

Elevate your material processing with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable vacuum tube furnaces, muffle furnaces, tube furnaces, rotary furnaces, and CVD/PECVD systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements for superior purity, precision, and performance. Contact us today to discuss how our furnaces can optimize your processes and deliver exceptional results!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab