When selecting a ceramic heating element supplier, you must look beyond the component's price and evaluate the manufacturer's technical expertise, material quality, and ability to customize for your specific application. A superior supplier acts as a technical partner, ensuring the element’s performance characteristics—like thermal stability and oxidation resistance—directly contribute to your product's efficiency, reliability, and long-term value.

Choosing the right supplier is not a procurement task; it is an engineering decision. The goal is to find a partner whose expertise in material science and customization directly translates into reduced downtime, improved energy efficiency, and predictable high-temperature performance for your system.

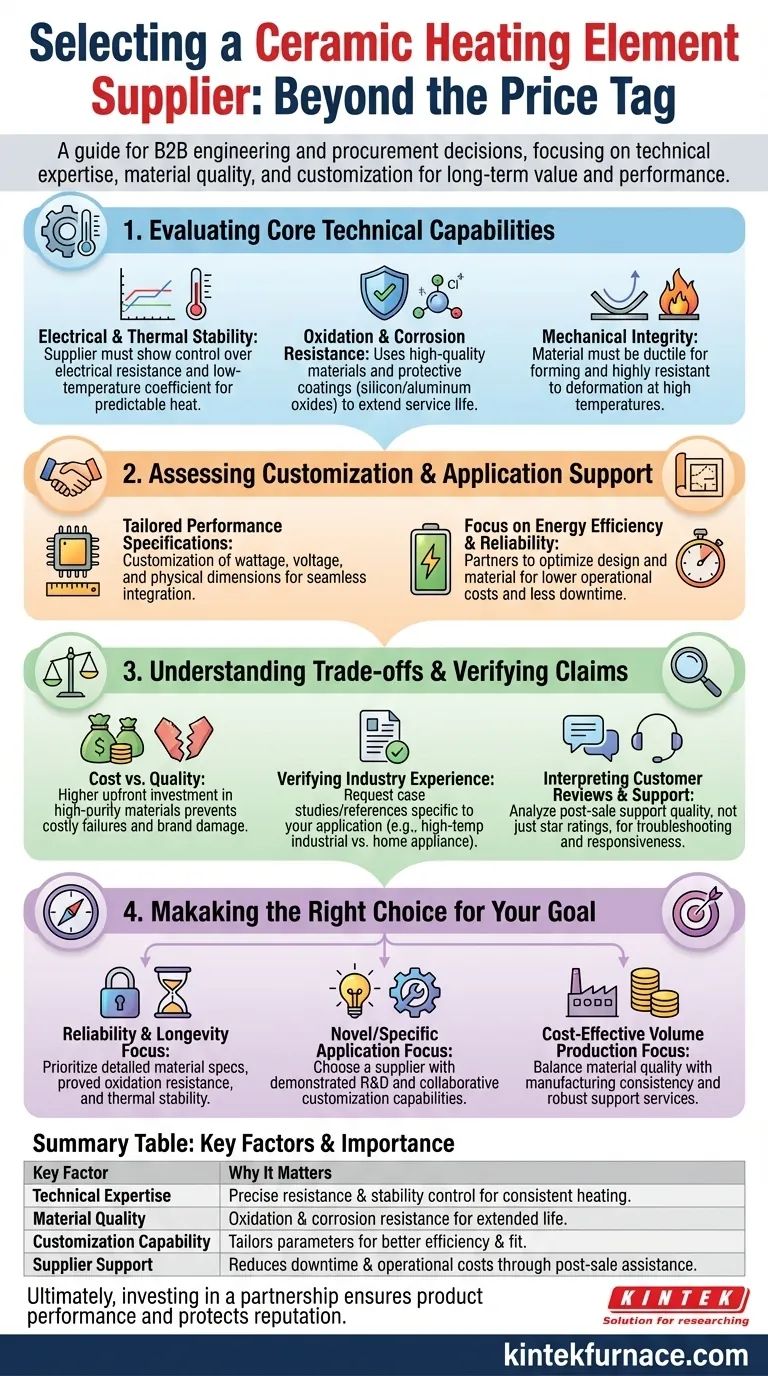

Evaluating Core Technical Capabilities

The performance of a ceramic heater is dictated by the materials used and the precision of its manufacturing. A trustworthy supplier will be transparent about these details and possess deep institutional knowledge.

Electrical and Thermal Stability

The primary function of a heating element is to convert electricity into heat consistently. The supplier must demonstrate control over the material's electrical resistance, ensuring it is high enough to generate heat but not so high that it acts as an insulator.

Furthermore, the material should have a low-temperature coefficient of resistance. This means its resistance remains stable across a wide range of operating temperatures, leading to predictable and controllable heat output.

Oxidation and Corrosion Resistance

At high temperatures, materials react with the air, leading to oxidation and degradation. A quality supplier uses ceramic compounds and protective coatings (such as silicon or aluminum oxides) that create a barrier, preventing this breakdown.

This resistance to oxidation is critical for extending the element's service life and preventing premature failure, especially in demanding industrial environments.

Mechanical Integrity at High Temperatures

The chosen material must be ductile enough to be formed into the required shape but also highly resistant to deformation once operating at its target temperature.

A high melting point is essential, as it allows the element to generate heat efficiently well below the temperature where it would change state or lose its structural integrity.

Assessing Customization and Application Support

An off-the-shelf heater rarely provides optimal performance. A premier supplier distinguishes itself by working with you to engineer a solution tailored to your exact needs.

Tailored Performance Specifications

Your supplier should have the capability to customize elements based on critical parameters. This includes specific wattage, voltage, and physical dimensions to ensure seamless integration into your product or system.

This level of customization is key to achieving the desired thermal profile and energy consumption targets.

Focus on Energy Efficiency and Reliability

A knowledgeable supplier helps you do more than just generate heat. They help you achieve it efficiently.

By optimizing the element's design and material composition, they can significantly improve energy efficiency and reduce operational costs. This partnership directly contributes to a more reliable end product with less downtime.

Understanding the Trade-offs and Verifying Claims

Every engineering choice involves compromises. A transparent supplier will help you navigate these, while a questionable one will obscure them.

The Cost vs. Quality Dilemma

High-purity ceramic materials and advanced coatings cost more upfront. However, this initial investment often prevents costly failures, warranty claims, and damage to your brand's reputation caused by unreliable, cheaper components.

Verifying Industry Experience

Ask for case studies or references specific to your industry or a similar application. A supplier with decades of experience in home appliances may not have the necessary expertise for high-temperature industrial furnaces.

Interpreting Customer Reviews and Support

Look beyond star ratings. Analyze reviews for details on how the supplier handles challenges, provides technical support, and responds when a component does not meet expectations. Strong post-sale support is a hallmark of a true partner.

Making the Right Choice for Your Goal

Your final decision should align with your project's primary objective.

- If your primary focus is maximum reliability and longevity: Prioritize suppliers who can provide detailed material specification sheets and prove their control over oxidation resistance and thermal stability.

- If your primary focus is a novel or highly specific application: Choose a supplier with demonstrated R&D capabilities and a collaborative approach to customizing wattage, voltage, and geometry.

- If your primary focus is cost-effective volume production: Balance material quality against manufacturing consistency and verify the supplier has robust support services to troubleshoot any issues that arise at scale.

Ultimately, selecting a supplier is about investing in a partnership that ensures your product's performance and protects your reputation.

Summary Table:

| Key Factor | Why It Matters |

|---|---|

| Technical Expertise | Ensures precise control over electrical resistance and thermal stability for consistent heating. |

| Material Quality | Provides oxidation and corrosion resistance, extending service life in demanding environments. |

| Customization Capability | Tailors wattage, voltage, and dimensions to fit specific applications for better efficiency. |

| Supplier Support | Offers strong post-sale assistance and reliability, reducing downtime and operational costs. |

Ready to enhance your product's performance with reliable ceramic heating elements? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure we meet your unique experimental requirements, delivering improved energy efficiency, reduced downtime, and predictable high-temperature performance. Contact us today to discuss how we can be your trusted technical partner!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What is the maximum temperature silicon carbide heating elements can withstand? Key Factors for Longevity and Performance

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance

- Why are SIC heating elements resistant to chemical corrosion? Discover the Self-Protecting Mechanism

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability

- What are the properties and capabilities of Silicon Carbide (SiC) as a heating element? Unlock Extreme Heat and Durability