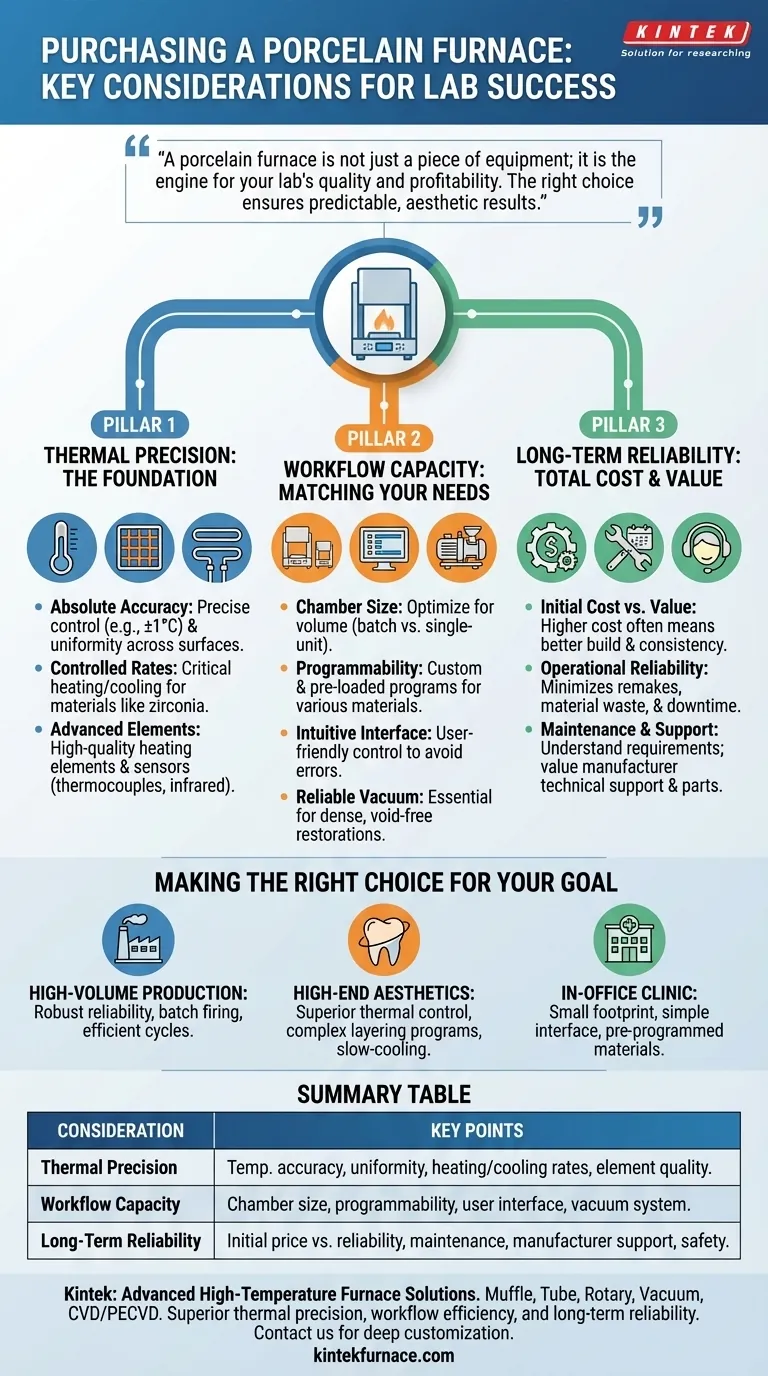

When selecting a porcelain furnace, your primary considerations must extend beyond the price tag to three core pillars: thermal precision, workflow capacity, and long-term operational reliability. These factors directly determine the quality of your restorations, the efficiency of your lab, and the profitability of your work by minimizing costly remakes and ensuring predictable results.

A porcelain furnace is not just a piece of equipment; it is the engine for your lab's quality and profitability. The right choice ensures predictable, aesthetic results for every case, making long-term reliability and thermal accuracy far more critical factors than the initial purchase price.

The Foundation: Achieving Thermal Precision

The single most important function of a porcelain furnace is to execute a firing program with absolute accuracy. Deviations in temperature, even minor ones, can ruin the aesthetic and structural integrity of a restoration.

Temperature Control and Uniformity

A furnace's ability to hit and hold a precise temperature is non-negotiable. Look for specifications on temperature control accuracy (e.g., ±1°C) and furnace temperature uniformity.

Uniformity ensures that a restoration, whether a single unit or a large bridge, is heated evenly across its entire surface, preventing weak spots or inconsistent shades.

Heating Rate and Cooling

Modern ceramic materials, especially zirconia and lithium disilicate, require precise control over the rate of heating and cooling.

Slow cooling capabilities are critical for preventing thermal shock and stress fractures in large or all-ceramic restorations. The ability to program these ramps is essential for material versatility.

Heating Elements and Sensors

The quality of the heating element, often made of molybdenum disilicide, determines its longevity and ability to produce stable heat.

Advanced furnaces may also incorporate infrared technology or multiple temperature sensors (thermocouples) to provide more accurate real-time feedback and control over the firing process, especially during the critical drying phase.

Matching the Furnace to Your Workflow

A furnace must fit the physical and operational needs of your laboratory or clinic. A feature that is perfect for a high-volume lab may be unnecessary for a smaller, in-office setting.

Firing Chamber Size and Material

The chamber size dictates how many restorations you can fire at once. While a larger chamber seems better, it may be less efficient for a lab that primarily handles single-unit cases.

The chamber's internal material, often a durable quartz or ceramic muffle, is designed for thermal stability and to prevent contamination of the restorations.

Programmability and User Interface

The furnace must be able to store numerous custom programs for the wide variety of ceramic materials on the market. Pre-loaded programs are helpful, but the ability to easily create and modify your own is essential.

Look for a straightforward control panel and a user interface that is intuitive. A complex system can lead to user error, while an overly simple one may lack the control needed for complex aesthetic cases.

Vacuum System

For firing porcelain, a reliable and powerful vacuum pump is just as important as the heating elements. It removes air from the muffle to create dense, void-free restorations. The furnace's ability to hold a strong, consistent vacuum is critical.

Understanding the Trade-offs and Total Cost

The sticker price of a furnace is only one part of its true cost. A cheap furnace that produces inconsistent results is far more expensive in the long run.

The Initial Price vs. Long-Term Reliability

A higher initial cost often correlates with superior components, better build quality, and more sophisticated temperature control systems.

Reliability is the most important long-term value. A furnace that works flawlessly for years, producing consistent results every time, eliminates the immense cost of remakes, wasted materials, and lost technician time.

Maintenance and Manufacturer Support

Understand the maintenance requirements for the muffle, heating elements, and vacuum pump. How easy is it to calibrate the temperature?

Investigate the manufacturer's reputation for technical support and parts availability. When a furnace goes down, your production stops, and responsive support is invaluable.

Common Pitfalls to Avoid

Do not prioritize niche features over core performance. A furnace with hundreds of programs is useless if it cannot hold a stable temperature.

Be wary of furnaces that lack robust safety features, such as overheating protection and a secure door seal. These are not just for operator safety but also for protecting the restorations inside.

Making the Right Choice for Your Goal

Select a furnace based on the specific demands of your work. The ideal choice is a balance of precision, capacity, and reliability tailored to your primary focus.

- If your primary focus is high-volume production: Prioritize a furnace with a reputation for robust reliability, a reasonably sized chamber for batch firing, and efficient heating/cooling cycles.

- If your primary focus is high-end aesthetics: Invest in a furnace with superior thermal control, advanced programming for complex layering, and proven slow-cooling capabilities.

- If your primary focus is an in-office clinic: Choose a furnace with a small footprint, an extremely simple user interface, and pre-programmed cycles for the specific materials you use most.

Ultimately, you are investing not just in a furnace, but in the consistency and quality of every restoration you create.

Summary Table:

| Consideration | Key Points |

|---|---|

| Thermal Precision | Temperature control accuracy, uniformity, heating/cooling rates, element/sensor quality |

| Workflow Capacity | Chamber size, programmability, user interface, vacuum system |

| Long-Term Reliability | Initial price vs. reliability, maintenance needs, manufacturer support, safety features |

Ready to elevate your lab's performance with a tailored porcelain furnace? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, delivering superior thermal precision, workflow efficiency, and long-term reliability. Contact us today to discuss how we can support your specific goals and boost your lab's productivity!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab