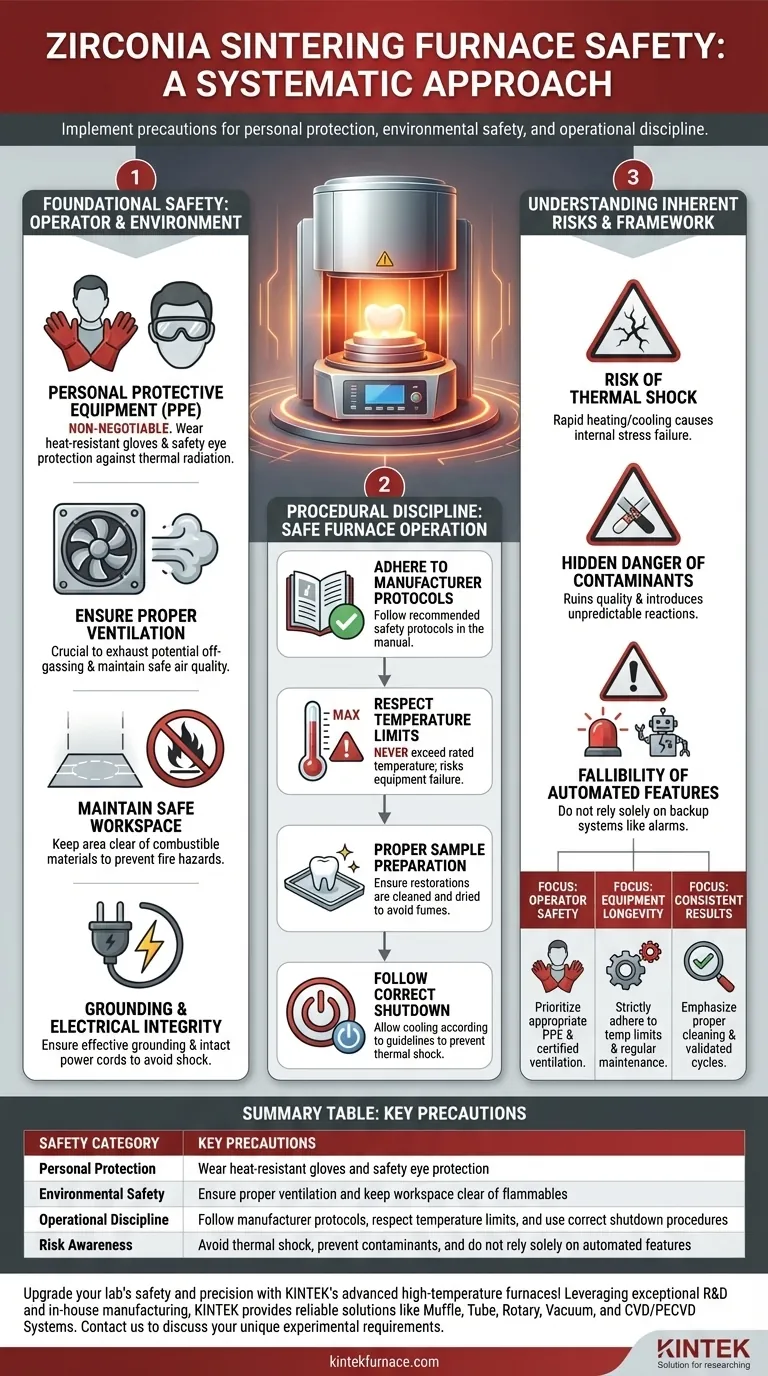

To safely operate a zirconia sintering furnace, you must implement a system of precautions covering personal protection, environmental safety, and strict operational discipline. This involves wearing heat-resistant personal protective equipment (PPE), ensuring the workspace has proper ventilation, and always adhering to the manufacturer's specified temperature limits and operating protocols.

The high temperatures essential for sintering zirconia introduce significant inherent risks, including severe burns, electrical hazards, and potential material failure. A comprehensive safety strategy is not merely a checklist but a disciplined system that protects the operator, the equipment, and the quality of the final restoration.

Foundational Safety: The Operator and the Environment

Before you even turn the furnace on, safety begins with preparing yourself and the workspace. These foundational steps mitigate the most common and immediate hazards.

Personal Protective Equipment (PPE) is Non-Negotiable

Operating this equipment without proper PPE exposes you to extreme heat. Always wear heat-resistant gloves when handling crucibles or accessing the furnace chamber.

You must also wear safety eye protection to shield your eyes from the intense thermal radiation emitted from the hot furnace interior.

Ensuring Proper Ventilation

Sintering furnaces operate at incredibly high temperatures. While pure zirconia is stable, any contaminants or binding agents within the restorations can release fumes.

Proper ventilation is crucial to exhaust any potential off-gassing and maintain a safe air quality in the lab or facility.

Maintaining a Safe Workspace

The furnace itself is a significant heat source. Keep the immediate area clear of all flammable or combustible materials, including chemicals, paper, and plastics, to prevent a fire hazard.

Grounding and Electrical Integrity

These are high-power devices that present a risk of electric shock if not properly installed. Ensure the furnace has effective electrical grounding and that all power cords and connections are in excellent condition, free from damage or wear.

Procedural Discipline: Safe Furnace Operation

Consistent, safe results depend on following a strict and repeatable operational process. Deviating from established procedures introduces risk to both the operator and the equipment.

Adhere to Manufacturer Protocols

The manufacturer's instruction manual is your primary guide. It contains specific safety warnings, operating steps, and maintenance schedules tailored to your exact model. Always follow these recommended safety protocols.

Respect Temperature Limits

Every furnace has a maximum rated temperature. Never exceed this limit, as doing so can damage the delicate heating elements, compromise the furnace chamber, and lead to equipment failure.

Proper Sample Preparation

Ensure any zirconia restoration placed in the furnace has been properly cleaned and dried. Contaminants on the surface can affect the final quality and may release unexpected fumes during the heating cycle.

Follow Correct Shutdown Procedures

Allow the furnace to cool down according to the manufacturer's guidelines. Abrupt temperature changes can cause thermal shock, potentially cracking the ceramic restorations or damaging the furnace's internal components.

Understanding the Inherent Risks

Recognizing the potential pitfalls is key to avoiding them. Complacency is often the greatest risk, especially for experienced operators.

The Risk of Thermal Shock

Zirconia and the furnace's ceramic components are strong but can be brittle. Rapid heating or cooling creates internal stresses that can cause catastrophic failure. This is why pre-programmed, gradual cycles are essential.

The Hidden Danger of Contaminants

Cross-contamination from other materials or improper handling can not only ruin the aesthetic and structural integrity of the restoration but can also introduce elements that may react unpredictably at high temperatures.

The Fallibility of Automated Features

Modern furnaces include safety features like over-temperature alarms and automatic shutdowns. While critical, these are backup systems. Do not rely on them as your primary method of safety; disciplined operation is always the first line of defense.

A Framework for Safe Sintering

Use your specific goal to guide your focus on safety, as each priority reinforces the others.

- If your primary focus is operator safety: Prioritize wearing appropriate PPE for every interaction with the furnace and ensuring the workspace has certified, functioning ventilation.

- If your primary focus is equipment longevity: Strictly adhere to the manufacturer's temperature limits and perform all recommended regular maintenance checks without fail.

- If your primary focus is consistent, high-quality results: Emphasize proper sample cleaning and exclusively use validated, pre-programmed sintering cycles to avoid thermal shock and ensure predictability.

Ultimately, a systematic and disciplined approach to safety is the foundation for achieving both personal well-being and superior clinical outcomes.

Summary Table:

| Safety Category | Key Precautions |

|---|---|

| Personal Protection | Wear heat-resistant gloves and safety eye protection |

| Environmental Safety | Ensure proper ventilation and keep workspace clear of flammables |

| Operational Discipline | Follow manufacturer protocols, respect temperature limits, and use correct shutdown procedures |

| Risk Awareness | Avoid thermal shock, prevent contaminants, and do not rely solely on automated features |

Upgrade your lab's safety and precision with KINTEK's advanced high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with reliable solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures these products precisely meet your unique experimental requirements, enhancing operator protection and equipment durability. Contact us today to discuss how we can support your safety goals and deliver superior performance!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures