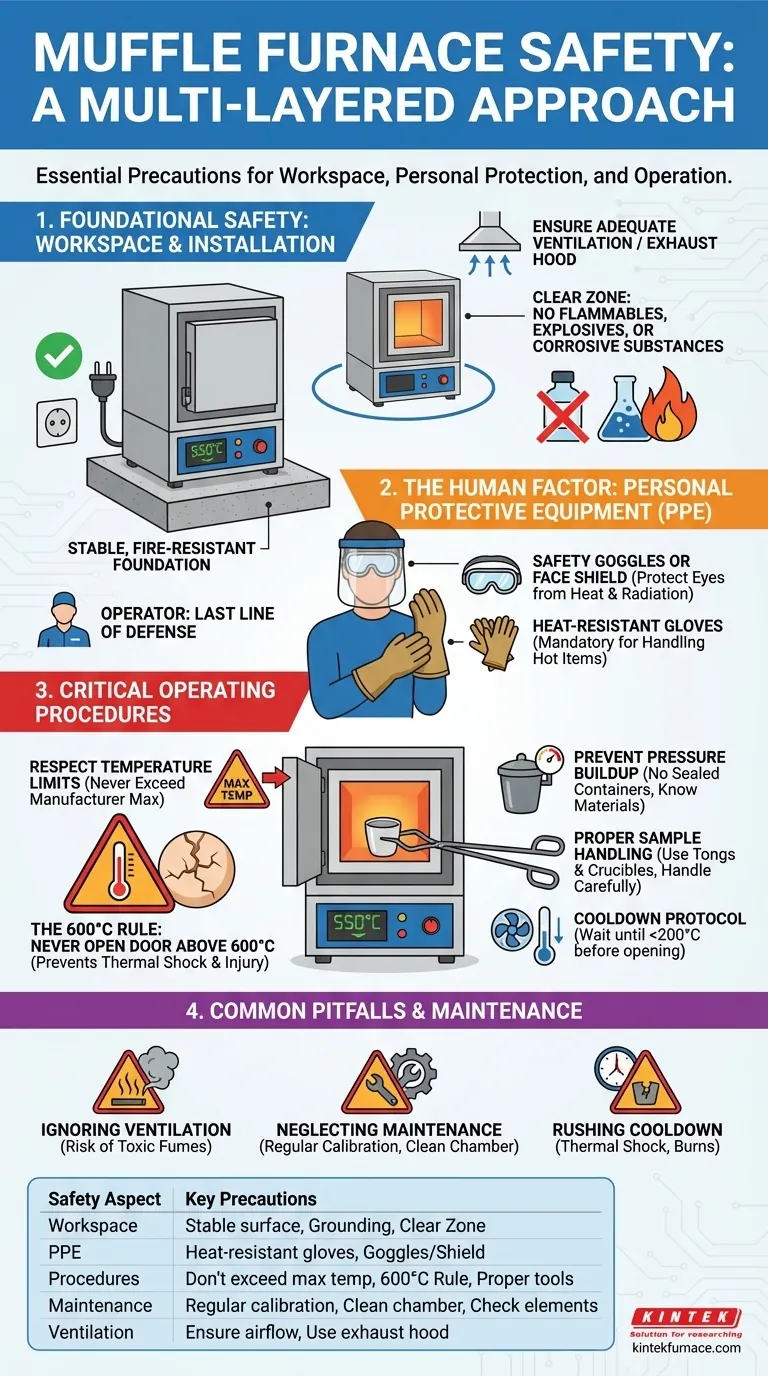

To operate a muffle furnace safely, you must adopt a multi-layered approach that addresses environmental setup, personal protection, operational discipline, and regular maintenance. Key precautions include wearing heat-resistant gloves and goggles, ensuring the furnace is on a stable, fire-proof surface in a well-ventilated area, never exceeding its maximum temperature, and never opening the door when the internal temperature is above 600°C.

A muffle furnace is not just an oven; it is a specialized tool that concentrates immense thermal and electrical energy. True safety isn't about memorizing rules, but about developing a deep respect for its three primary hazards: extreme heat, high-voltage electricity, and the potential for volatile chemical reactions.

Foundational Safety: The Workspace and Installation

Before you ever turn the furnace on, safety begins with its physical environment. An improper setup is a leading cause of accidents.

Electrical Integrity and Grounding

The furnace requires significant power, making proper electrical connections non-negotiable. Ensure the unit is connected to a circuit with the correct plugs, sockets, and fuses specified by the manufacturer.

Crucially, the furnace must be properly grounded to prevent the risk of electric shock, especially in the event of an internal electrical fault.

A Stable, Fire-Resistant Foundation

Place the furnace on a sturdy, level surface, such as a cement platform or a fire-resistant lab bench. This prevents tipping and ensures that any incidental heat transfer does not create a fire hazard below the unit.

Maintaining a "Clear Zone"

The area around the muffle furnace must be kept completely free of flammable, explosive, or corrosive substances. This clear zone acts as a buffer, preventing accidental ignition from the furnace's high external surface temperatures.

The Human Factor: Personal Protective Equipment (PPE)

Even with a perfect setup, the operator is the last line of defense. Appropriate PPE is mandatory.

Essential Hand and Eye Protection

Always wear heat-resistant gloves when handling items that will be placed in or removed from the furnace. Standard lab gloves offer no protection from thermal burns.

Safety goggles or a face shield are also essential to protect your eyes from intense heat radiation, especially when viewing the interior through a spyhole or briefly opening the door during cooldown.

Critical Operating Procedures: From Startup to Shutdown

Strict adherence to operational protocol is the key to preventing accidents during use.

Respecting Temperature Limits

Never attempt to operate the furnace above its manufacturer-specified maximum temperature. Doing so can damage the heating elements and refractory materials, creating a severe safety risk.

Avoid running the furnace at its maximum rated temperature for extended periods, as this shortens its lifespan and increases the risk of failure.

The 600°C Rule: Preventing Thermal Shock

Never open the furnace door when the internal temperature is above 600°C. The rapid influx of cool air can cause thermal shock, potentially cracking the furnace's ceramic chamber and leading to catastrophic failure. This also exposes the operator to a blast of superheated air.

Preventing Pressure Buildup

Be aware of what you are heating. Certain materials can release large volumes of gas, creating pressure buildup inside the sealed chamber. If working with unknown or reactive materials, use small quantities and slow heating ramps.

Never place sealed containers, liquids, or materials that can produce explosive byproducts inside the furnace.

Proper Sample Handling

Use appropriate tools, such as long-handled tongs and high-temperature-resistant crucibles or trays, to load and unload samples. Always handle items carefully and close the furnace door gently to avoid jarring the internal components.

The Cooldown Protocol

After a cycle is complete, turn off the power. Once the temperature has dropped significantly (ideally below 200°C), you can slightly open the door to aid in cooling. Rushing this process can damage both the furnace and your sample.

Understanding the Common Pitfalls

Many incidents occur not from a single major failure, but from a gradual neglect of best practices.

Pitfall 1: Ignoring Ventilation

One of the most common mistakes is failing to ensure adequate ventilation. Ashing, burning, or heat-treating samples can release noxious or toxic fumes. Always operate the furnace in a well-ventilated room or under a dedicated exhaust hood, especially during ashing or incineration processes.

Pitfall 2: Neglecting Calibration and Maintenance

An uncalibrated furnace gives false temperature readings, which can ruin experiments and pose a safety risk. Periodically check the temperature calibration against a certified thermocouple.

Regularly inspect heating elements for signs of wear and clean the chamber to prevent residue buildup, which can contaminate future samples and become a fire hazard.

Pitfall 3: Rushing the Cooldown

Impatience is a significant risk factor. Attempting to remove a sample when the furnace is still too hot can lead to severe burns and damage the equipment through thermal shock. Always allow the furnace to cool according to procedure.

Making the Right Choice for Your Goal

Your specific application dictates which safety protocols require the most attention.

- If your primary focus is routine sample ashing or drying: Prioritize excellent ventilation to manage fumes and regular cleaning to prevent cross-contamination and residue buildup.

- If you are working with novel or reactive materials: Prioritize slow heating ramps, small sample sizes, and constant monitoring for unexpected reactions or pressure changes.

- If you are responsible for lab management: Prioritize creating and enforcing a Standard Operating Procedure (SOP), providing thorough training, and maintaining a strict calibration and maintenance log.

Ultimately, consistent, disciplined operation is the only way to ensure safety when working with the power of a muffle furnace.

Summary Table:

| Safety Aspect | Key Precautions |

|---|---|

| Workspace Setup | Stable fire-proof surface, proper grounding, clear zone from flammables |

| Personal Protection | Heat-resistant gloves, safety goggles or face shield |

| Operational Procedures | Never exceed max temperature, avoid opening door above 600°C, use proper tools |

| Maintenance | Regular calibration, inspect heating elements, clean chamber |

| Ventilation | Ensure adequate airflow, use exhaust hood for fumes |

Ensure your lab's safety and efficiency with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability precisely meets your unique experimental needs, enhancing performance and reducing risks. Contact us today to discuss how we can support your specific requirements and deliver tailored solutions for a safer, more productive environment!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals