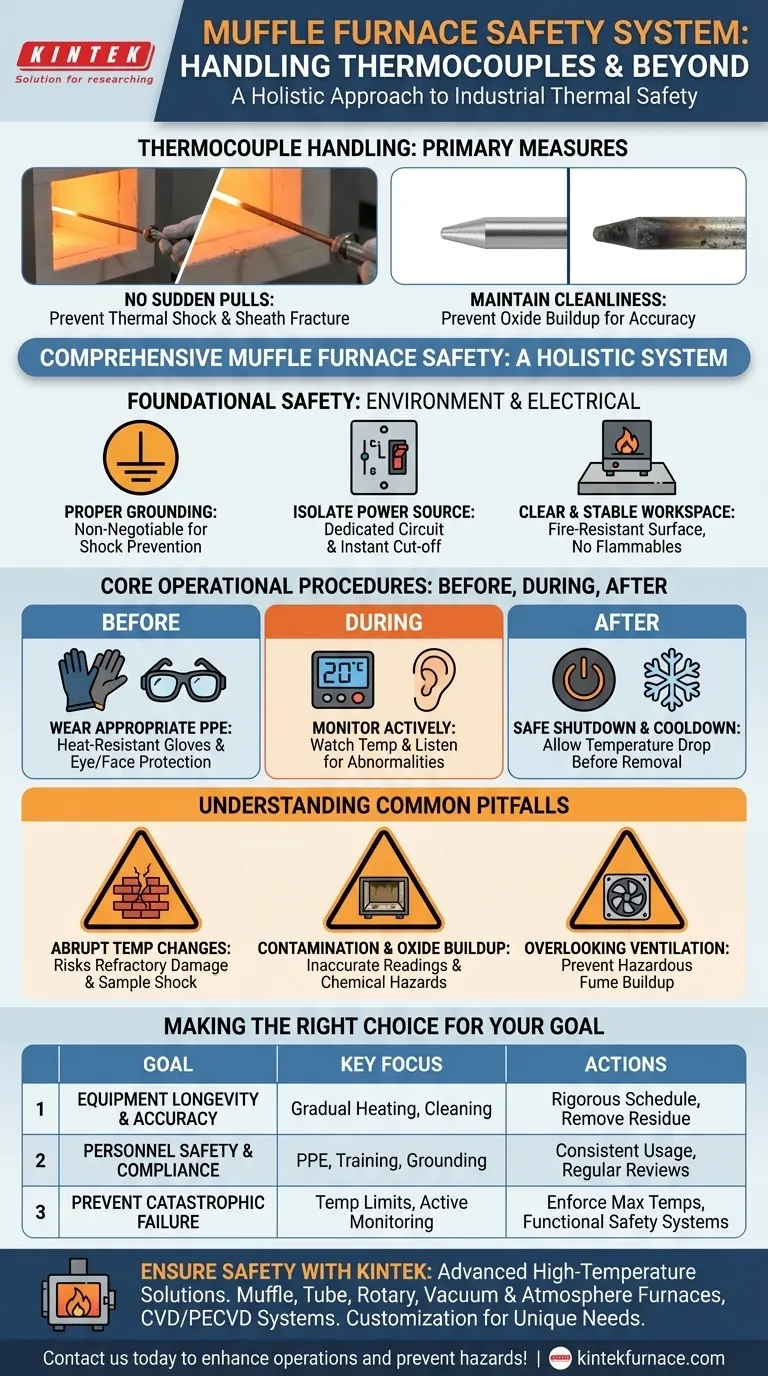

When handling a thermocouple in a muffle furnace, your primary safety measures are to prevent thermal shock and maintain a clean environment. Never pull a thermocouple out suddenly from high temperatures, as the rapid cooling can cause its protective sheath to fracture. You must also keep the furnace and the thermocouple free of oxides and other residues, as this buildup can compromise temperature accuracy and lead to material contamination.

While specific thermocouple handling is important, comprehensive muffle furnace safety is a holistic system. It requires treating the furnace not as a simple oven, but as a piece of industrial equipment with significant thermal, electrical, and environmental risks that must be managed systematically.

Foundational Safety: The Environment and Electrical Setup

Before you even turn the furnace on, you must establish a safe operating environment. Errors in setup are a leading cause of accidents.

Proper Grounding is Non-Negotiable

Every muffle furnace must be properly grounded according to electrical codes. This is your primary defense against electric shock in the event of an internal wiring failure.

Isolate the Power Source

The furnace should be connected to a dedicated circuit with an appropriate fuse or circuit breaker. Using a separate, clearly labeled power control switch or "gate" allows you to cut all power to the unit instantly in an emergency.

Maintain a Clear and Stable Workspace

Place the furnace on a flat, stable, and fire-resistant surface, such as a cement platform. The area surrounding the furnace must be kept completely clear of all flammable, explosive, or corrosive materials.

Core Operational Procedures: Before, During, and After Heating

Rigorous, repeatable procedures are essential for mitigating hazards during furnace operation. Every operator must be trained on these steps.

Always Wear Appropriate PPE

The extreme heat radiated by a furnace necessitates heat-resistant gloves and safety glasses or a face shield at all times when interacting with the unit. Proper ventilation is also critical to dissipate heat and any potential off-gassing from samples.

Respect Temperature Limits and Ramping Rates

Never exceed the manufacturer's maximum rated temperature. Furthermore, do not operate the furnace at its maximum temperature for prolonged periods, as this shortens the life of heating elements and refractory materials.

Monitor the Furnace Actively

During operation, pay close attention to the temperature display and listen for any unusual sounds. If you observe any abnormalities or unexpected temperature fluctuations, cut the power immediately and investigate once the unit is safe.

Follow Strict Door-Handling Rules

Never open the furnace door when the internal temperature is above 600°C unless absolutely required by a specific, risk-assessed process. The sudden rush of cool air can cause thermal shock, damaging the furnace lining and potentially the samples. Always close the door gently.

Execute a Safe Shutdown and Cooldown

After a cycle is complete, turn off the power. Once the temperature has dropped to a safe level, you may remove the samples. Slightly opening the door can aid in cooling, but do not leave it wide open.

Understanding Common Pitfalls

Even with established procedures, certain risks are often underestimated. Awareness of these common failure points is critical for advanced safety.

The Risk of Abrupt Temperature Changes

The warning against pulling a thermocouple out suddenly applies to the entire system. Rapid heating or cooling can crack the refractory brick lining, damage heating elements, and shatter certain samples, leading to contamination and costly repairs.

Contamination and Oxide Buildup

Allowing oxides, residue, or spilled sample material to accumulate inside the furnace is a significant hazard. This buildup can react with heating elements, thermocouples, or future samples, leading to inaccurate temperature readings and unpredictable chemical reactions at high heat.

Overlooking Ventilation

While a muffle furnace may not produce visible smoke, heating certain materials can release hazardous fumes. Inadequate ventilation can lead to a buildup of these fumes in the workspace, creating a respiratory hazard.

Operator Complacency

The biggest risk in any routine operation is complacency. Familiarity can lead operators to skip steps, forget PPE, or ignore minor abnormalities. Regular training and safety reviews are essential to combat this.

Making the Right Choice for Your Goal

Your primary safety focus should align with your operational objective.

- If your primary focus is equipment longevity and accuracy: Prioritize gradual heating/cooling cycles and a rigorous cleaning schedule to remove all oxides and residue.

- If your primary focus is personnel safety and compliance: Mandate consistent PPE usage, conduct regular operator training, and ensure electrical grounding and emergency shutdown procedures are tested.

- If your primary focus is preventing catastrophic failure: Strictly enforce maximum temperature limits, ensure over-temperature protection systems are functional, and train operators for active monitoring and emergency response.

Ultimately, treating the muffle furnace as an integrated system—not just a heating box—is the key to ensuring safe operation and repeatable results.

Summary Table:

| Safety Aspect | Key Measures |

|---|---|

| Thermocouple Handling | Avoid sudden removal, prevent thermal shock, keep clean |

| Electrical Setup | Ensure proper grounding, use dedicated circuit, isolate power |

| Operational Procedures | Wear PPE, respect temperature limits, monitor actively, handle door carefully |

| Common Pitfalls | Avoid abrupt temperature changes, prevent contamination, ensure ventilation, combat complacency |

| Safety Focus Areas | Equipment longevity, personnel safety, catastrophic failure prevention |

Ensure your lab's safety and efficiency with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide muffle, tube, rotary, vacuum & atmosphere furnaces, and CVD/PECVD systems, all with deep customization to meet your unique needs. Contact us today to discuss how our products can enhance your operations and prevent hazards!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites