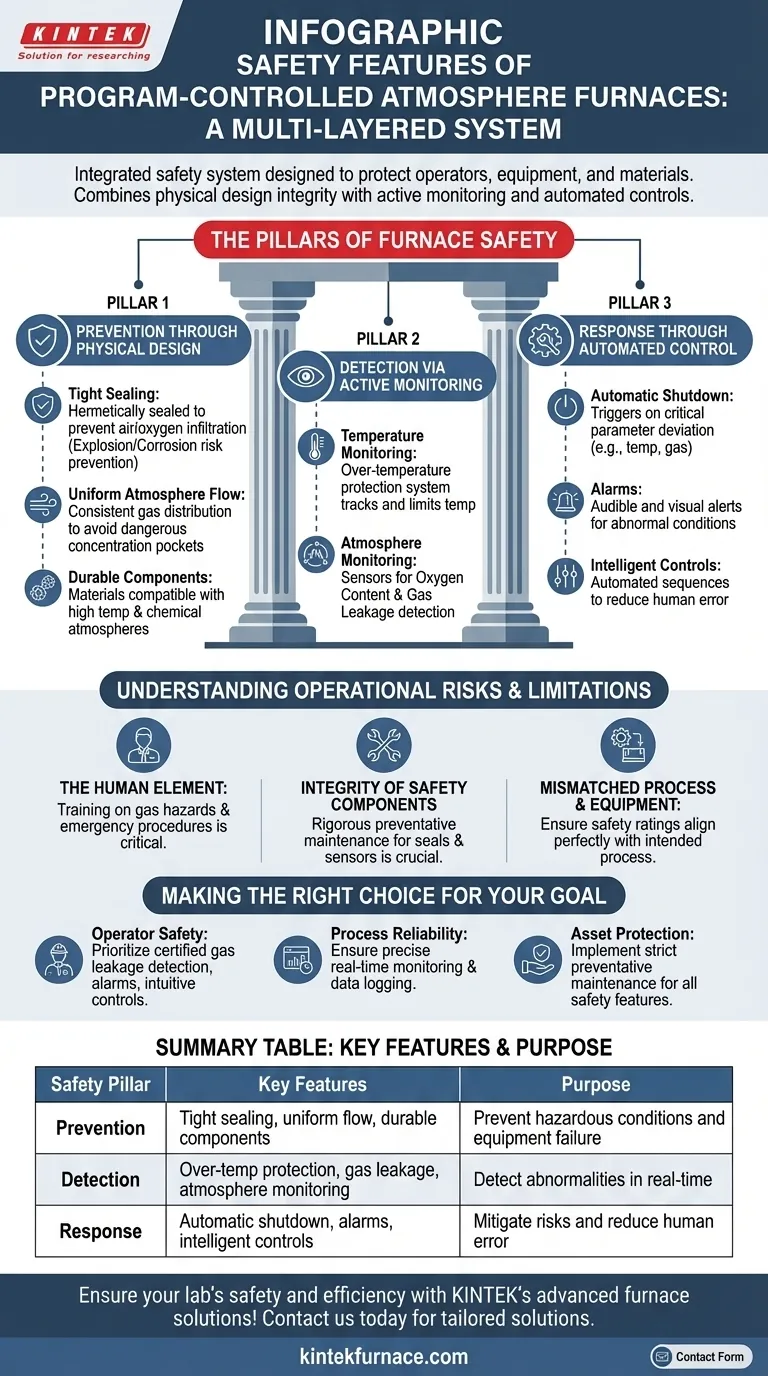

At its core, a program-controlled atmosphere furnace is equipped with a multi-layered safety system designed to protect operators, the equipment, and the materials being processed. This system combines physical design integrity with active monitoring and automated controls. Key features include over-temperature protection, gas leakage detection, automatic shutdown protocols, and robust sealing to prevent hazardous atmospheric mixing.

The safety of an atmosphere furnace is not reliant on a single feature but on an integrated system. This system works to prevent hazardous conditions, detect abnormalities in real-time, and respond automatically to mitigate risk before an incident occurs.

The Pillars of Furnace Safety

True safety in a high-temperature, controlled-atmosphere environment is achieved through a system of overlapping protections. These can be understood as three distinct but interconnected pillars: prevention, detection, and response.

Pillar 1: Prevention Through Physical Design

The first line of defense is a furnace built to contain its environment and withstand operational stresses.

- Tight Sealing: The furnace chamber must be hermetically sealed. This is critical for preventing external air, particularly oxygen, from infiltrating the furnace and reacting with the controlled atmosphere, which could create an explosive or corrosive mixture.

- Uniform Atmosphere Flow: A well-designed system ensures consistent gas distribution. This prevents pockets of incorrect gas concentrations from forming, ensuring both process consistency and safety.

- Durable Components: Heating elements and internal structures are specifically chosen to be compatible with the high temperatures and chemical nature of the atmospheres used. This prevents premature degradation and failure.

Pillar 2: Detection via Active Monitoring

Even with a robust physical design, the system must continuously monitor for deviations from the safe operating window.

- Temperature Monitoring: An over-temperature protection system is a fundamental feature. It constantly tracks the furnace temperature and will trigger a response if it exceeds a pre-set safety limit, preventing damage to the furnace and the workload.

- Atmosphere Monitoring: Sensors monitor critical atmospheric parameters. This often includes oxygen content analysis to detect air leaks and gas leakage detection to identify hazardous gases escaping into the work area.

Pillar 3: Response Through Automated Control

When a potential hazard is detected, the furnace's control system must take immediate, automated action.

- Automatic Shutdown: If a critical parameter like temperature or gas concentration goes out of bounds, the system can automatically shut down the heating elements, stop the flow of hazardous gases, or initiate an emergency purge.

- Alarms: The system will trigger audible and visual alarms to alert operators to an abnormal condition, allowing for manual intervention if necessary.

- Intelligent Controls: Modern furnaces use advanced control systems that simplify operation. By automating complex sequences, these systems reduce the risk of human error, which remains a significant cause of industrial accidents.

Understanding Operational Risks and Limitations

While modern furnaces have advanced safety features, they do not eliminate risk entirely. User knowledge and proper maintenance are indispensable.

The Human Element Remains Critical

Automation reduces but does not replace the need for skilled operators. Users must be thoroughly trained on the specific hazards of the gases being used (e.g., flammability, toxicity) and the correct emergency procedures.

Integrity of Safety Components

Safety systems are only effective if they are functional. Seals can degrade over time, sensors can drift or fail, and interlocks can malfunction. A rigorous preventative maintenance schedule is crucial to ensure these protective features work when needed.

Mismatched Process and Equipment

Using a furnace with gases or at temperatures for which it was not designed is a primary cause of failure. The safety ratings and material compatibility of the furnace must align perfectly with the intended process to ensure safe operation.

Making the Right Choice for Your Goal

To maximize safety, align the furnace's capabilities and your operational procedures with your primary goal.

- If your primary focus is operator safety: Prioritize models with certified gas leakage detection, robust alarm systems, and intuitive controls that minimize the potential for user error.

- If your primary focus is process reliability: Ensure the furnace's control system offers precise, real-time monitoring and data logging of temperature and atmospheric composition to prevent deviations.

- If your primary focus is asset protection: Implement a strict preventative maintenance schedule for all seals, sensors, and safety interlocks to guarantee they function correctly for the life of the equipment.

A truly safe operation is achieved when advanced equipment features are paired with rigorous operator knowledge and disciplined procedures.

Summary Table:

| Safety Pillar | Key Features | Purpose |

|---|---|---|

| Prevention | Tight sealing, uniform atmosphere flow, durable components | Prevent hazardous conditions and equipment failure |

| Detection | Over-temperature protection, gas leakage detection, atmosphere monitoring | Detect abnormalities in real-time |

| Response | Automatic shutdown, alarms, intelligent controls | Mitigate risks and reduce human error |

Ensure your lab's safety and efficiency with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability precisely meets your unique experimental needs. Contact us today to discuss how our tailored solutions can protect your operators, processes, and assets!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What are the development prospects of atmosphere box furnaces in the aerospace industry? Unlock Advanced Material Processing for Aerospace Innovation

- How does a batch type controlled atmosphere furnace operate? Master Precision Heat Treatment for Superior Materials

- What are the primary inert gases used in vacuum furnaces? Optimize Your Heat Treatment Process

- What are the key features of an atmosphere box furnace? Unlock Precise Heat Processing in Controlled Environments

- How is the sealing performance of an experimental box type atmosphere furnace enhanced? Boost Purity with Advanced Sealing Systems