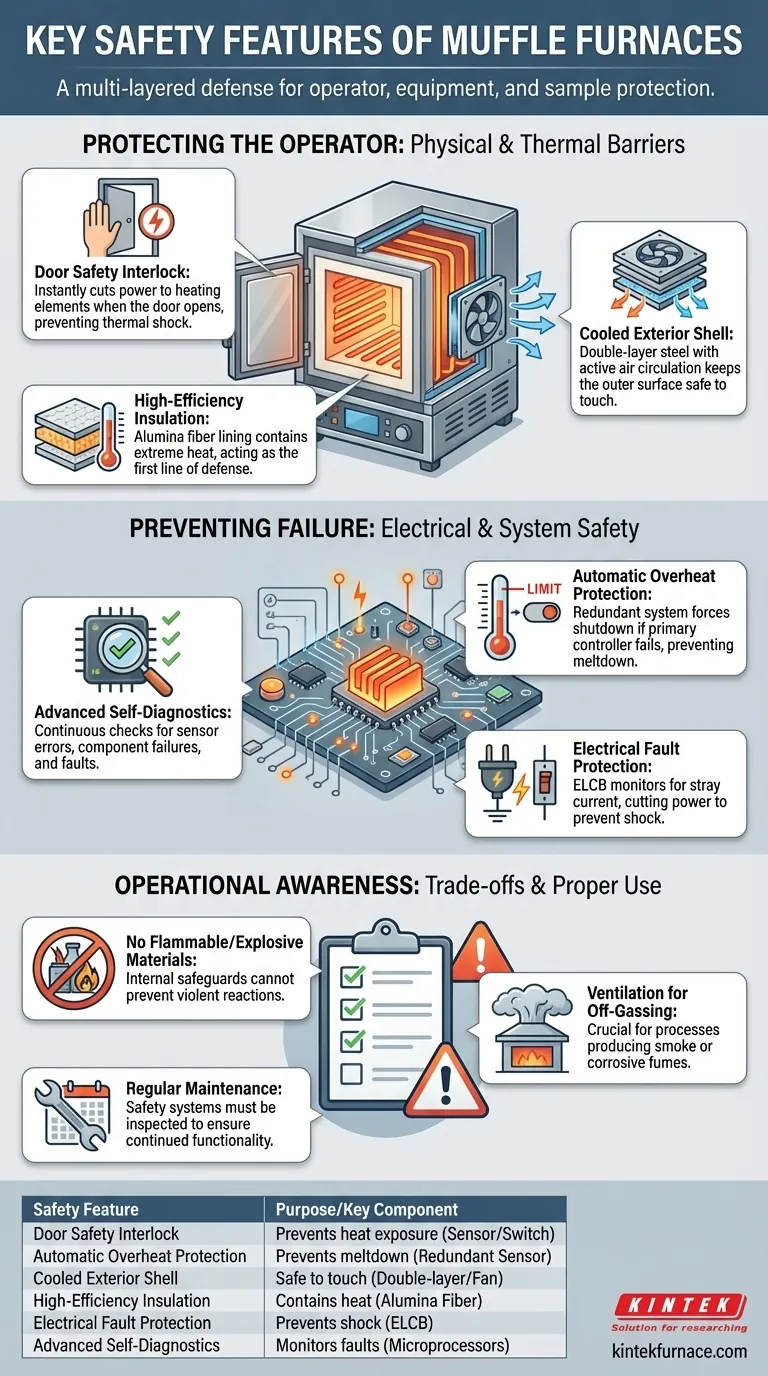

At their core, muffle furnaces integrate a suite of safety features designed to mitigate the inherent risks of extreme heat and high-voltage electricity. These protections can be categorized into three main areas: physical and thermal barriers protecting the operator, electronic systems that prevent catastrophic equipment failure, and operational controls that ensure predictable behavior. The most critical of these are the door safety interlock, automatic overheat protection, and a robust, insulated external casing.

A truly safe muffle furnace is not defined by a single feature, but by a defense-in-depth system. This system combines passive design choices like insulation with active electronic monitoring and physical interlocks to comprehensively protect the user, the sample, and the equipment itself.

Protecting the Operator: Physical and Thermal Safety

The most immediate dangers from a muffle furnace are severe burns and exposure to extreme temperatures. Modern designs address this with several layers of physical protection.

The Door Safety Interlock

This is arguably the most important active safety feature for the user. A sensor or switch is integrated into the door mechanism.

When the door is opened, this interlock immediately cuts power to the heating elements. This prevents accidental exposure to the chamber's intense radiant heat and protects the user from thermal shock.

Cooled Exterior Shell

Contact with the furnace's exterior should never cause a burn. This is achieved with a double-layer steel structure that creates an air gap between the inner and outer walls.

A built-in air cooling fan often circulates air through this gap, actively dissipating heat and keeping the outer surface at a safe-to-touch temperature, even when the interior is at its maximum.

High-Efficiency Insulation

The chamber is lined with high-purity, heat-resistant materials like alumina fiber insulation. While its primary goal is energy efficiency and temperature stability, it plays a crucial safety role.

This insulation is what contains the extreme heat within the chamber, forming the first line of defense in preventing heat from reaching the furnace's outer body.

Preventing Failure: Electrical and System Safety

Beyond direct user protection, a safe furnace must be able to protect itself from self-destruction and prevent electrical hazards. These features often operate in the background, preventing dangerous conditions before they arise.

Automatic Overheat Protection

This is a non-negotiable, redundant safety system. It uses a separate sensor or control circuit that constantly monitors the chamber temperature.

If the primary temperature controller fails and the furnace begins to exceed its maximum safe temperature, the overheat protection system will forcibly shut down the heating elements. This is the key defense against furnace meltdown and fire.

Advanced Self-Diagnostics

Modern furnaces incorporate microprocessors that continuously run diagnostics. This system acts as a watchdog, looking for faults that could lead to an uncontrolled state.

Common checks include:

- Sensor Errors: Detects a broken or disconnected thermocouple.

- SSR/Triac Short Circuits: Identifies a failure in the solid-state relays that control the heaters, which could cause them to be stuck "on."

- Heater Disconnection: Alerts the user if a heating element has failed.

Electrical Fault Protection

All furnaces should be equipped with an Earth Leakage Circuit Breaker (ELCB) or a similar ground fault interrupter.

This device monitors for any stray electrical current escaping the intended circuit to the furnace chassis. If a fault is detected, it instantly cuts all power, protecting operators from severe electric shock.

Understanding the Trade-offs and Operational Risks

While modern furnaces are incredibly safe, their features are not a substitute for proper procedure and an understanding of their limitations.

Features vs. Proper Use

Safety systems are designed to protect against accidental misuse or unexpected equipment failure. They are not designed to contain the intentional heating of inappropriate materials.

Never place flammable, explosive, or highly reactive materials inside a muffle furnace. The internal safeguards cannot prevent a violent chemical reaction.

The Hidden Risk of Off-Gassing

Many processes, such as binder burnout or ashing, produce smoke, fumes, or corrosive gases. A furnace's vent port is critical for safely exhausting these byproducts.

However, using a furnace without a proper vent for a process that off-gasses can lead to a buildup of toxic fumes in the lab or cause corrosive damage to the furnace interior and heating elements.

The Importance of Maintenance

Safety features, particularly sensors and mechanical interlocks, can wear out or fail over time. A furnace that appears to be working may have a disabled or faulty safety system. Regular inspection and maintenance are critical to ensure all protections remain functional.

Making the Right Choice for Your Goal

When evaluating a muffle furnace, match its safety profile to its intended application.

- If your primary focus is general lab use with standard materials: Prioritize robust thermal insulation, a reliable door interlock, and automatic overheat protection.

- If your primary focus is unattended or long-duration processes: Insist on a model with advanced self-diagnostics, power-fail recovery logic, and an earth leakage breaker.

- If your primary focus is processing materials that produce byproducts: Ensure the furnace has an appropriately sized vent port and is constructed from materials resistant to potential off-gassing.

Ultimately, a comprehensive understanding of these integrated safety systems empowers you to protect your personnel, your equipment, and your results.

Summary Table:

| Safety Feature | Purpose | Key Components |

|---|---|---|

| Door Safety Interlock | Prevents exposure to heat by cutting power on door open | Sensor, switch mechanism |

| Automatic Overheat Protection | Shuts down furnace to prevent meltdown and fire | Redundant sensor, control circuit |

| Cooled Exterior Shell | Keeps outer surface safe to touch | Double-layer steel, air cooling fan |

| High-Efficiency Insulation | Contains heat and improves safety | Alumina fiber insulation |

| Electrical Fault Protection | Prevents electric shock | Earth Leakage Circuit Breaker (ELCB) |

| Advanced Self-Diagnostics | Monitors for system faults | Microprocessors, sensor checks |

Ensure your lab's safety and efficiency with KINTEK's advanced high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability precisely meets your unique experimental requirements, integrating top safety features for reliable performance. Contact us today to discuss how our furnaces can protect your personnel and equipment while enhancing your research outcomes!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment