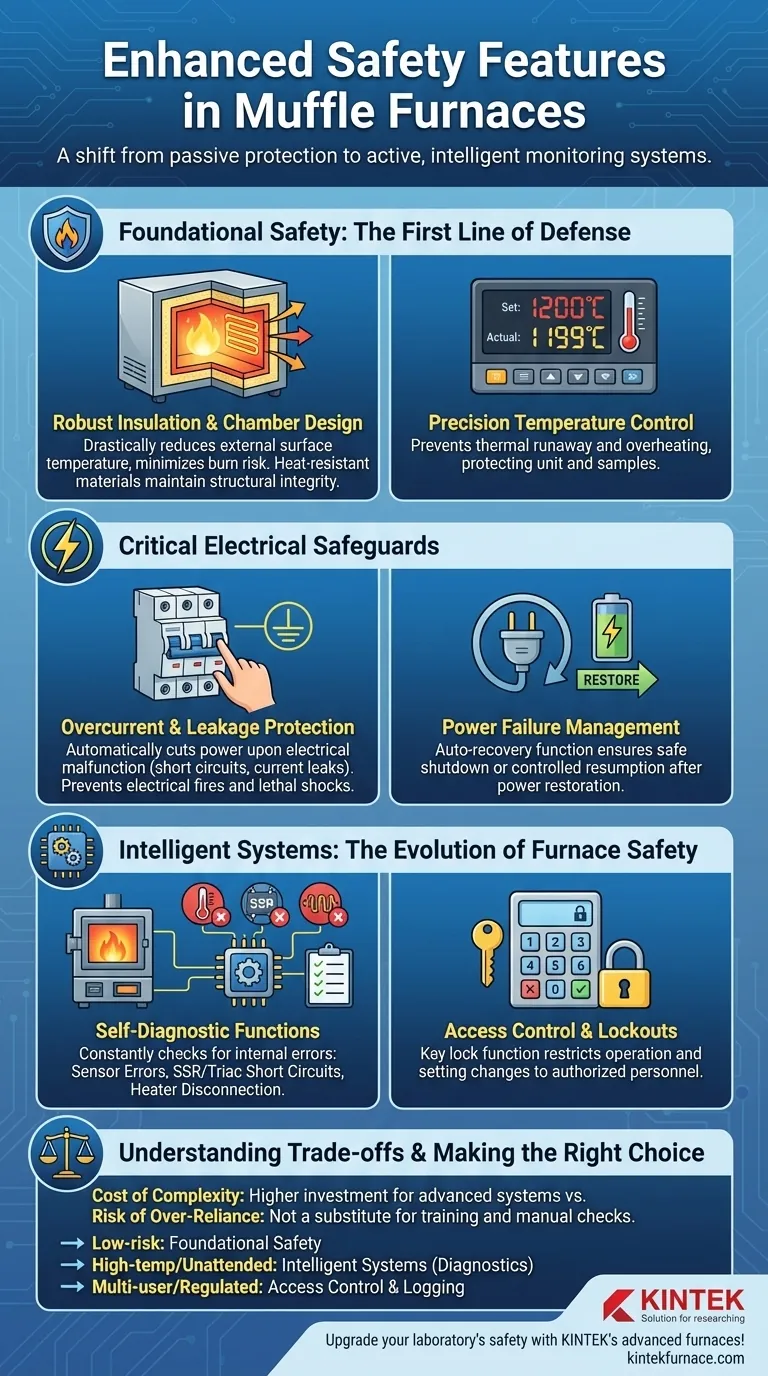

Enhanced safety in muffle furnaces is achieved by integrating intelligent electronic systems with fundamental physical protections. Modern units move beyond basic insulation and include features like self-diagnostic functions that check for sensor or component failures, advanced electrical safeguards like earth leakage breakers, and access control systems to prevent unauthorized use.

The core evolution in muffle furnace safety is the shift from passive protection, like heat insulation, to active, intelligent systems. These modern features continuously monitor the furnace's health to prevent accidents before they happen, rather than just containing them.

Foundational Safety: The First Line of Defense

Every muffle furnace is built on a foundation of passive safety features designed to protect the operator and the surrounding environment from extreme heat.

Robust Insulation and Chamber Design

The most fundamental safety feature is a highly insulated chamber. This design drastically reduces the external surface temperature of the furnace, minimizing the risk of accidental burns during operation.

These furnaces are also built with heat-resistant materials that maintain structural integrity at very high temperatures, preventing warping or failure that could expose the heating elements.

Precision Temperature Control

An advanced temperature control system is critical for both performance and safety. Its primary safety function is to prevent overheating.

By precisely maintaining the set temperature, the controller ensures the furnace does not enter a thermal runaway condition, which could damage the unit, the sample, and create a fire hazard.

Critical Electrical Safeguards

Given that muffle furnaces are high-power electrical devices, robust safeguards against electrical faults are non-negotiable for preventing equipment damage, fire, and electric shock.

Overcurrent and Leakage Protection

Modern furnaces are equipped with circuit breakers or earth leakage breakers. These devices automatically cut power to the unit if they detect an electrical malfunction, such as a short circuit or a current leak.

This feature is a critical defense against electrical fires and protects operators from potentially lethal shocks.

Power Failure Management

Select models include an auto-recovery function for power failures. This ensures that when power is restored, the furnace either safely shuts down or resumes its heating cycle in a controlled manner, preventing unexpected and potentially dangerous state changes.

Intelligent Systems: The Evolution of Furnace Safety

The most significant enhancements in furnace safety come from onboard microprocessors that actively monitor the system's status. These are the features that distinguish a modern furnace from an older one.

Self-Diagnostic Functions

A self-diagnostic system is the furnace's brain, constantly checking for internal errors. It typically monitors:

- Sensor Errors: Ensures the temperature reading is accurate. A faulty sensor could lead to dangerous overheating.

- SSR or Triac Short Circuits: Detects failures in the solid-state relays that control the heating elements, preventing them from being stuck in the "on" position.

- Heater Disconnection: Alerts the user if a heating element has failed, preventing an operator from assuming the furnace is cool when it might not be.

Access Control and Lockouts

A key lock function provides an essential layer of administrative control. It prevents untrained personnel from operating the furnace or changing critical settings on a running process. This is vital in multi-user lab or industrial environments to ensure consistent protocol and safety.

Understanding the Trade-offs

While advanced safety features are highly beneficial, it's important to view them within a complete operational context.

The Cost of Complexity

Furnaces with comprehensive self-diagnostic systems and advanced controls typically have a higher initial purchase price. While this investment enhances safety, it must be balanced against the application's risk profile and budget.

The Risk of Over-Reliance

Automated safety features are not a substitute for proper training and manual safety checks. Operators can become complacent, assuming the machine will handle everything. Regular inspection, maintenance, and adherence to standard operating procedures remain essential for safe use.

Making the Right Choice for Your Goal

Selecting a furnace requires matching its safety features to your specific application and work environment.

- If your primary focus is routine, low-risk applications: A furnace with robust insulation, reliable temperature control, and a standard circuit breaker provides a solid baseline of safety.

- If your primary focus is high-temperature or unattended operation: Prioritize models with comprehensive self-diagnostic functions, especially for heater and sensor errors, and automatic overheat prevention.

- If your primary focus is a multi-user or regulated environment: Insist on features like key locks, detailed error logging, and calibration offsets to ensure accountability and operational security.

Ultimately, choosing a furnace with the right safety profile transforms it from a simple heat source into a reliable and secure instrument for your work.

Summary Table:

| Safety Feature Category | Key Components | Primary Benefits |

|---|---|---|

| Foundational Safety | Robust insulation, precision temperature control | Prevents burns, overheating, and thermal runaway |

| Electrical Safeguards | Circuit breakers, earth leakage breakers, auto-recovery | Reduces fire and electric shock risks |

| Intelligent Systems | Self-diagnostics, access control, key locks | Enables proactive monitoring and prevents unauthorized use |

Upgrade your laboratory's safety and efficiency with KINTEK's advanced high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with tailored solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your unique experimental needs, enhancing reliability and security. Don't compromise on safety—contact us today to discuss how our furnaces can protect your operations and drive innovation!

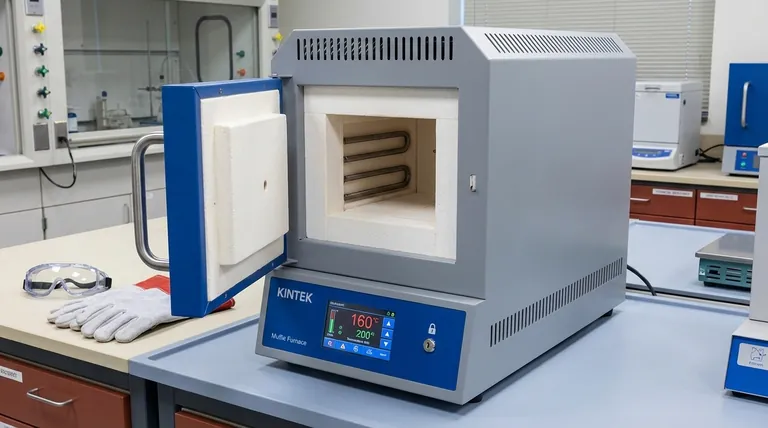

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment