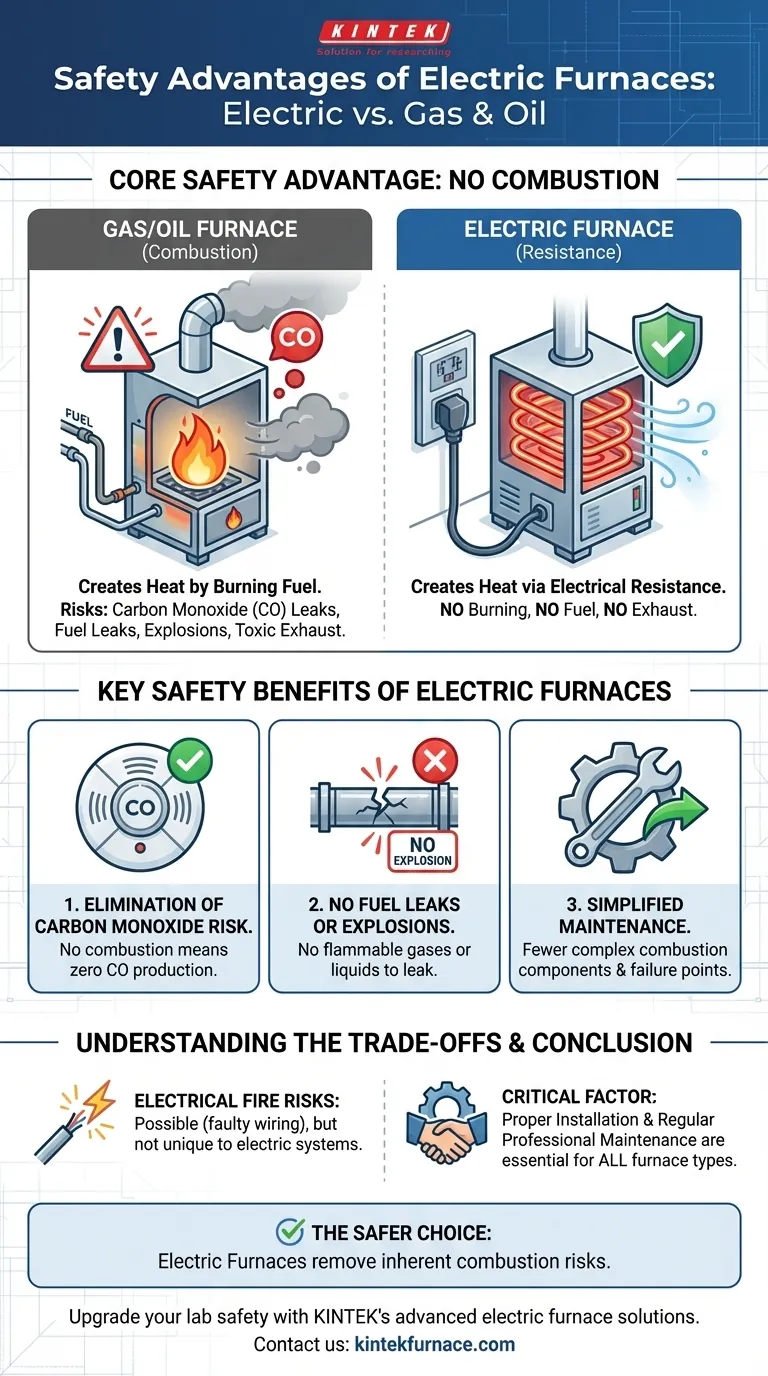

From a pure safety standpoint, an electric furnace presents fewer inherent risks than its gas or oil counterparts. By using electrical resistance to generate heat, it completely eliminates the dangers associated with burning fossil fuels, namely carbon monoxide poisoning and the potential for explosive gas leaks.

The core safety advantage is simple: electric furnaces don't burn anything. This removes an entire category of combustion-related hazards, such as fuel leaks and toxic exhaust gases, that are an unavoidable part of gas and oil heating systems.

The Fundamental Difference: Resistance vs. Combustion

Understanding furnace safety begins with understanding how each type generates heat. The method itself is the primary source of risk.

How Gas and Oil Furnaces Create Heat

A gas or oil furnace is essentially a carefully controlled fire. It works by pumping fuel (natural gas, propane, or oil) into a combustion chamber, igniting it, and then transferring the heat into your home's air via a component called a heat exchanger.

This process requires a constant supply of fuel and a way to vent dangerous exhaust gases, including carbon monoxide, out of your home.

How Electric Furnaces Create Heat

An electric furnace operates on a much simpler principle, much like a giant toaster or a powerful hair dryer. It draws electricity from your home's panel and passes it through a series of large coils called heating elements.

As these elements resist the flow of electricity, they glow red hot. A blower fan then pushes air across these superheated elements, warming it before distributing it through your ductwork. No fuel is burned, and no exhaust is created.

Key Safety Advantages of Electric Furnaces

This fundamental difference in operation gives electric furnaces three major safety advantages.

Elimination of Carbon Monoxide (CO) Risk

Carbon monoxide is a colorless, odorless gas produced during the incomplete combustion of fossil fuels. In a gas or oil furnace, a cracked heat exchanger or a blocked exhaust flue can allow this lethal gas to leak into your living space.

Because electric furnaces do not burn fuel, they do not produce carbon monoxide. This single fact makes them an inherently safer option, removing the most severe risk associated with central heating.

No Risk of Fuel Leaks or Explosions

Natural gas and propane are highly flammable. A leak from a supply line, a faulty valve, or a malfunctioning pilot light can fill an area with explosive fumes, creating a catastrophic risk.

Electric furnaces use no combustible fuel. This completely removes the danger of a gas leak and the subsequent risk of an explosion.

Simplified Maintenance and Fewer Failure Points

Gas and oil furnaces have complex components related to combustion, including gas valves, ignitors, burners, and heat exchangers. Each of these is a potential point of failure that carries a safety implication.

Electric furnaces have a simpler design, with the primary components being the heating elements, sequencer, and blower motor. While these can fail, they typically do not create life-threatening hazards like a CO leak.

Understanding the Trade-offs: Safety Is Not Absolute

While electric furnaces remove combustion risks, no heating system is entirely without safety considerations. Objectivity requires acknowledging the risks associated with any high-powered appliance.

Electrical Fire Hazards

Like any device that draws significant electrical current, an electric furnace carries a risk of electrical fire. This can be caused by faulty wiring, an overloaded circuit, or a component failure.

These risks are not unique to electric furnaces—gas furnaces also rely on high-voltage electrical components—but they are the primary safety concern for an all-electric system.

The Critical Role of Installation and Maintenance

The ultimate safety of any furnace—gas, oil, or electric—depends heavily on proper installation and regular professional maintenance.

An improperly installed electric furnace can create a fire hazard, just as a poorly maintained gas furnace can lead to a CO leak. Annual inspections are critical for all system types to ensure wiring is secure, safety switches are functional, and mechanical parts are in good working order.

Making the Right Choice for Your Goal

Your decision should be based on a clear understanding of the different risk profiles and your own priorities.

- If your primary focus is minimizing inherent system risk: An electric furnace is the superior choice, as it completely designs out the dangers of combustion, gas leaks, and carbon monoxide.

- If you have an existing gas or oil furnace: Your priority should be rigorous annual maintenance by a qualified technician and ensuring you have multiple, functional carbon monoxide detectors in your home.

- If you are weighing cost against safety: Acknowledge the superior safety of electric systems while factoring in that their operating costs can be significantly higher than natural gas in many regions.

Ultimately, a well-maintained system installed by a professional is the foundation of a safe home, regardless of the fuel type you choose.

Summary Table:

| Safety Feature | Electric Furnace | Gas/Oil Furnace |

|---|---|---|

| Carbon Monoxide Risk | None | High (requires ventilation) |

| Fuel Leak/Explosion Risk | None | High (flammable fuel) |

| Combustion Byproducts | None | Present (toxic exhaust) |

| Primary Safety Concern | Electrical fire | CO poisoning, explosions |

Upgrade to a safer, more reliable heating solution for your lab. At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions that prioritize safety without compromising performance. Our electric furnace product line—including Muffle, Tube, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is designed with deep customization capabilities to meet your unique experimental needs. Contact us today to learn how our electric furnaces can enhance your lab's safety and efficiency!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents