In biomedical fields, muffle furnaces serve as indispensable tools for creating, testing, and sterilizing materials where absolute purity and specific physical properties are non-negotiable. They are used for advanced material processing for medical implants, analytical testing of drugs and tissues through ashing, and high-temperature sterilization of durable equipment.

A muffle furnace is more than just a high-temperature oven; it is a precision instrument designed for contaminant-free heating. Its critical role in biomedicine stems from its ability to isolate a sample from the heating elements, ensuring that processes like material creation and analysis are conducted with uncompromising purity.

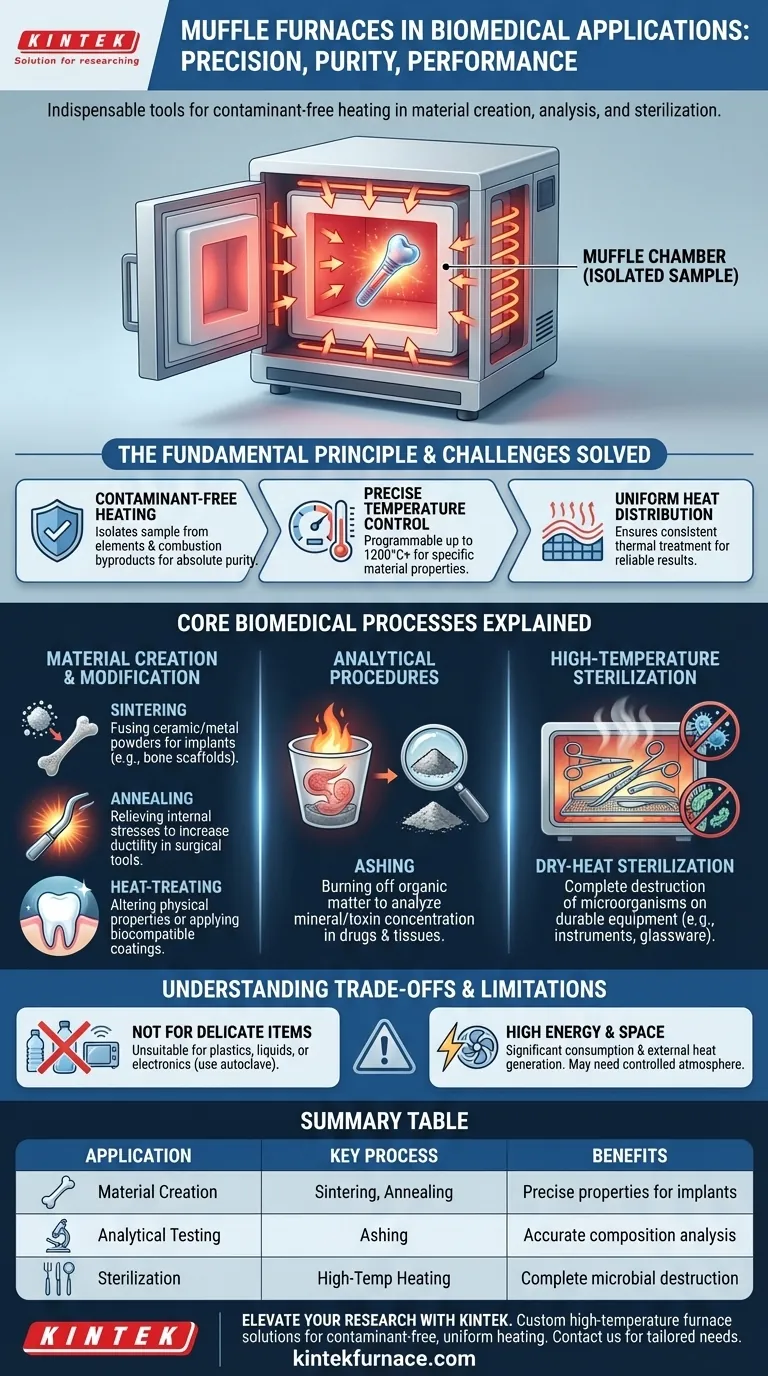

The Fundamental Principle: Why a Muffle Furnace?

At its core, a muffle furnace solves three critical challenges in biomedical work: contamination, imprecision, and inconsistency. It achieves this through a unique design that separates it from a standard oven.

Contaminant-Free Heating

The defining feature of a muffle furnace is the "muffle"—a sealed inner chamber that houses the material being treated. This chamber isolates the sample from the raw heating elements and any potential byproducts of combustion.

This isolation is paramount in biomedical applications, where even microscopic contaminants can compromise the biocompatibility of an implant or the results of a chemical analysis.

Precise Temperature Control

Muffle furnaces offer exceptionally precise and programmable temperature control, often reaching 1200°C or higher.

Biomedical materials, from metallic alloys for implants to advanced ceramics, require specific heat-treatment profiles to achieve their desired strength, porosity, or surface characteristics. A few degrees of deviation can ruin the final product.

Uniform Heat Distribution

The insulated chamber ensures that heat is distributed evenly throughout the entire volume. This uniformity guarantees that every part of a sample—whether it's a batch of ceramic crowns or a tissue sample for analysis—receives the exact same thermal treatment.

This consistency is essential for producing reliable, repeatable results in both manufacturing and laboratory testing.

Core Biomedical Processes Explained

The unique capabilities of a muffle furnace enable several key processes that are foundational to modern medicine and research.

Material Creation and Modification

Many advanced medical devices would not be possible without the material transformations that occur inside a furnace.

Sintering is a process where ceramic or metal powders are heated below their melting point until their particles fuse together. This is used to create durable, porous structures for bone implants and dental crowns.

Annealing involves heating a metal and then cooling it slowly to remove internal stresses and increase its ductility. This is vital for shaping metallic implants and surgical tools, preventing them from becoming brittle.

Heat-treating is a general term for altering the physical properties of a material. In biomedicine, this can be used to create specific crystalline structures in alloys or apply biocompatible enamel coatings to implants.

Analytical Procedures

The furnace is a destructive but powerful tool for understanding the composition of a sample.

Ashing is the most common analytical use. A biological or pharmaceutical sample is heated to a high temperature to completely burn off all organic matter.

What remains is an inorganic ash, which can then be analyzed to precisely measure the concentration of essential minerals or toxic heavy metals. This is used in quality control for drugs and nutritional analysis of tissue.

High-Temperature Sterilization

For durable, non-sensitive items, a muffle furnace provides a form of dry-heat sterilization.

It is used for metal surgical instruments and heat-resistant glassware. The extreme temperatures ensure the complete destruction of all microorganisms, including resilient spores that can survive other methods.

Understanding the Trade-offs and Limitations

While powerful, a muffle furnace is a specialized tool and not a universal solution. Understanding its limitations is key to using it appropriately.

Not for All Sterilization

The extreme heat makes muffle furnaces unsuitable for sterilizing plastics, liquids, textiles, or any delicate electronic equipment. For these items, an autoclave (which uses pressurized steam at lower temperatures) is the correct instrument.

Significant Energy Consumption

These are industrial-grade instruments that consume a substantial amount of electricity to reach and maintain high temperatures. They also generate significant external heat, requiring dedicated space and safety protocols in a lab environment.

Basic vs. Controlled Atmospheres

A standard muffle furnace operates using the ambient air in the chamber. However, some advanced materials are sensitive to oxygen at high temperatures. For these applications, a more complex and expensive furnace capable of creating a controlled atmosphere (e.g., nitrogen or argon) is required.

Making the Right Choice for Your Application

Selecting the right thermal processing method depends entirely on your end goal.

- If your primary focus is material development (e.g., implants, ceramics): Your priority should be a furnace with highly programmable temperature controls and exceptional uniformity to achieve specific material properties.

- If your primary focus is analytical testing (e.g., ashing): You need a furnace that guarantees uniform heating and has proper ventilation to ensure accurate, repeatable quantitative results.

- If your primary focus is sterilizing robust instruments: A basic, reliable muffle furnace that reaches the required temperature is sufficient, but always consider if a less energy-intensive autoclave could serve the purpose.

Ultimately, understanding the core principle of contaminant-free, precise heating empowers you to leverage the muffle furnace for the demanding applications where it truly excels.

Summary Table:

| Application | Key Process | Benefits |

|---|---|---|

| Material Creation | Sintering, Annealing | Achieves precise material properties for implants and devices |

| Analytical Testing | Ashing | Provides accurate mineral and toxin analysis in drugs and tissues |

| Sterilization | High-temperature heating | Ensures complete microbial destruction for durable equipment |

Ready to elevate your biomedical research with precision heating solutions? KINTEK specializes in advanced high-temperature furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Leveraging our exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs—ensuring contaminant-free, uniform heating for material creation, analysis, and sterilization. Contact us today to discuss how our tailored furnace solutions can drive innovation and reliability in your lab!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating