The working conditions inside your furnace chamber are not just a detail; they are a primary driver of the furnace's fundamental design. The type of atmosphere (such as inert gas or a vacuum) you require directly dictates the furnace's structure, sealing mechanisms, and material requirements. Failing to match the furnace to these conditions will result in failed processes, damaged samples, or even a compromised furnace.

Your selection process should not start with the furnace, but with the environment you need to create. The required atmosphere and vacuum level determine the necessary engineering for sealing, material compatibility, and structural integrity, making them the most critical factors after temperature.

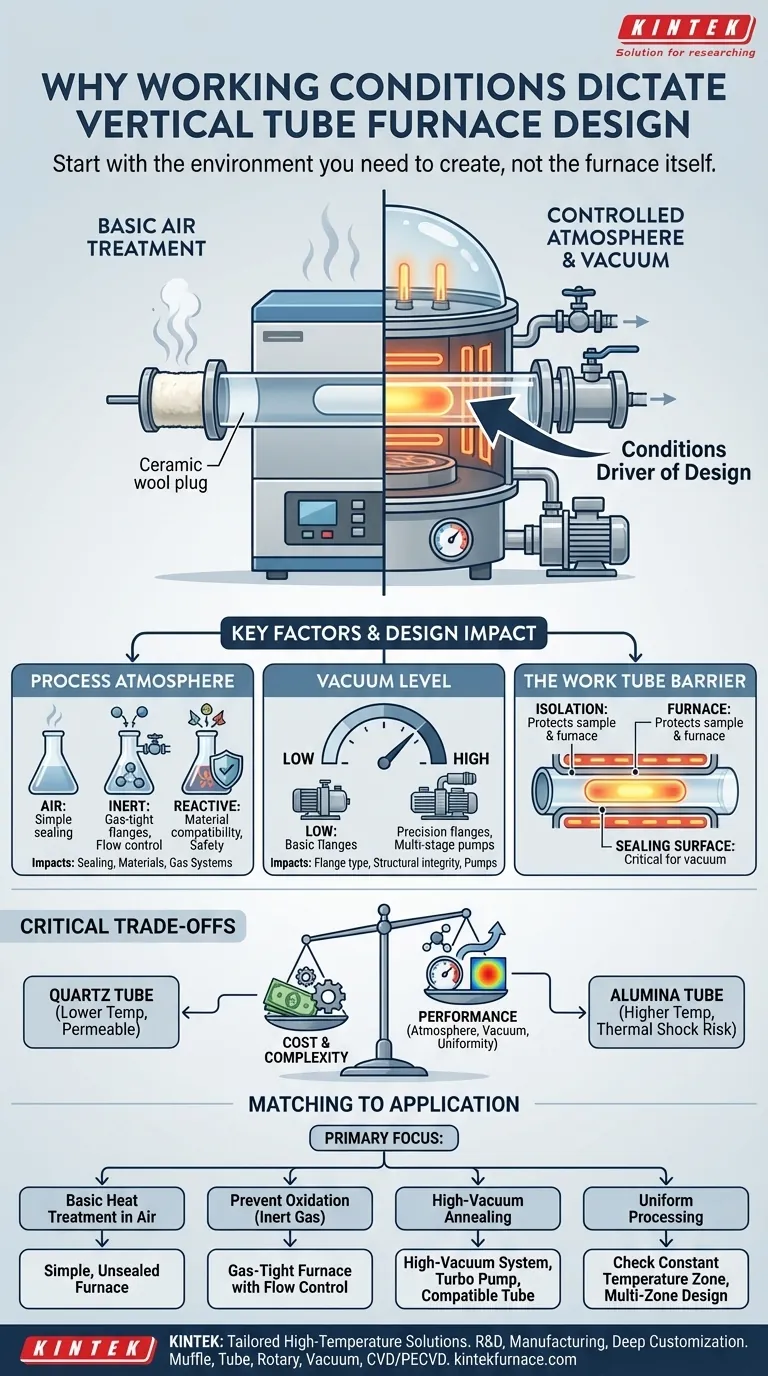

Why Working Conditions Dictate Furnace Design

A vertical tube furnace is more than a simple heater; it is a precisely controlled environmental chamber. The internal conditions you need to achieve for your process place specific demands on the furnace's construction.

Factor 1: Process Atmosphere

The gas environment surrounding your sample is a critical process variable.

-

Processing in Air: This is the simplest condition and requires no special sealing. The tube ends can be open or simply insulated with ceramic wool plugs.

-

Inert Atmospheres (e.g., Nitrogen, Argon): These are used to prevent oxidation. This requires a sealed system with gas-tight flanges, an inlet for the gas, and an outlet vent. The quality of the seal determines how effectively ambient air is excluded.

-

Reactive Atmospheres (e.g., Hydrogen): These gases actively participate in the process. This demands not only excellent sealing but also careful material selection, as reactive gases can degrade certain tube materials or heating elements at high temperatures.

Factor 2: Vacuum Level

Creating a vacuum places significant mechanical stress on the system and requires specialized components.

-

Low Vacuum: Achieving a rough vacuum to simply remove the bulk of ambient air can be done with basic sealing flanges and a simple mechanical pump.

-

High Vacuum: Reaching high or ultra-high vacuum levels is far more demanding. It requires precision-machined flanges, specific O-ring materials, and a multi-stage pump system (e.g., a turbo pump backed by a mechanical pump). The furnace tube and all components must be rated to withstand the significant pressure difference without leaking or collapsing.

Factor 3: The Work Tube as a Barrier

The work tube (typically quartz or alumina) is the core of your controlled environment.

-

Isolation: The tube isolates your sample and process atmosphere from the furnace's heating elements and insulation. This prevents contamination of your sample and protects the furnace from corrosive process byproducts.

-

Sealing Surface: The ends of the tube provide the critical sealing surface for the vacuum flanges. The quality and cleanliness of the tube ends are essential for achieving a good seal.

Understanding the Critical Trade-offs

Choosing a furnace involves balancing performance with cost and complexity. The working conditions you specify are the biggest driver of this trade-off.

Atmosphere Control vs. Cost

A furnace capable of holding a high vacuum with advanced gas handling is a significantly more complex and expensive piece of equipment than one designed for simple heat treatment in air. Each component—from the flanges to the pumps and gas controllers—adds to the total cost.

Chamber Size vs. Thermal Uniformity

The specified size of a furnace chamber is not the same as its constant temperature zone. This uniform zone is always smaller than the total heated length. To ensure your sample is heated evenly, it must fit entirely within this constant temperature zone. A larger uniform zone requires a more sophisticated (and often multi-zone) heating design.

Material Compatibility

The material of the work tube must be chosen carefully. Quartz is common and cost-effective but has a lower maximum temperature (~1100-1200°C) and can be permeable to certain gases like helium at high temperatures. Alumina offers a much higher operating temperature (~1700°C) but is more expensive and susceptible to thermal shock if heated or cooled too quickly.

Matching the Furnace to Your Application

Use your required working conditions as the primary filter for your selection.

- If your primary focus is basic heat treatment in air: A simple, unsealed furnace with insulation plugs will be the most cost-effective choice.

- If your primary focus is preventing oxidation with inert gas: You need a furnace equipped with gas-tight sealing flanges and a basic gas flow control system.

- If your primary focus is high-vacuum annealing: Your selection must prioritize a high-vacuum flange system, a compatible turbo pump, and a tube material rated for vacuum at high temperatures.

- If your primary focus is uniform processing of larger samples: Pay close attention to the furnace's specified "constant temperature zone" to ensure it can accommodate your entire workload.

By defining your required atmosphere, vacuum, and thermal uniformity first, you transform the selection process from a guess into a precise engineering decision.

Summary Table:

| Factor | Key Considerations | Impact on Furnace Design |

|---|---|---|

| Process Atmosphere | Air, inert gas, or reactive gas | Sealing, material compatibility, gas flow systems |

| Vacuum Level | Low to high vacuum | Flange type, pump systems, structural integrity |

| Thermal Uniformity | Constant temperature zone size | Heating design, sample placement, multi-zone options |

| Work Tube Material | Quartz or alumina | Temperature limits, gas permeability, thermal shock resistance |

Ready to select the perfect vertical tube furnace for your lab? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your specific working conditions. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements. Don't compromise on performance—contact us today to discuss how we can enhance your material processing with reliable, efficient furnace technology!

Visual Guide

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How does a vertical tube furnace facilitate the simulation of the industrial sintering process for iron ores?

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- How does a tube heating furnace facilitate the carbon coating process? Boost Layered Oxide Conductivity

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision