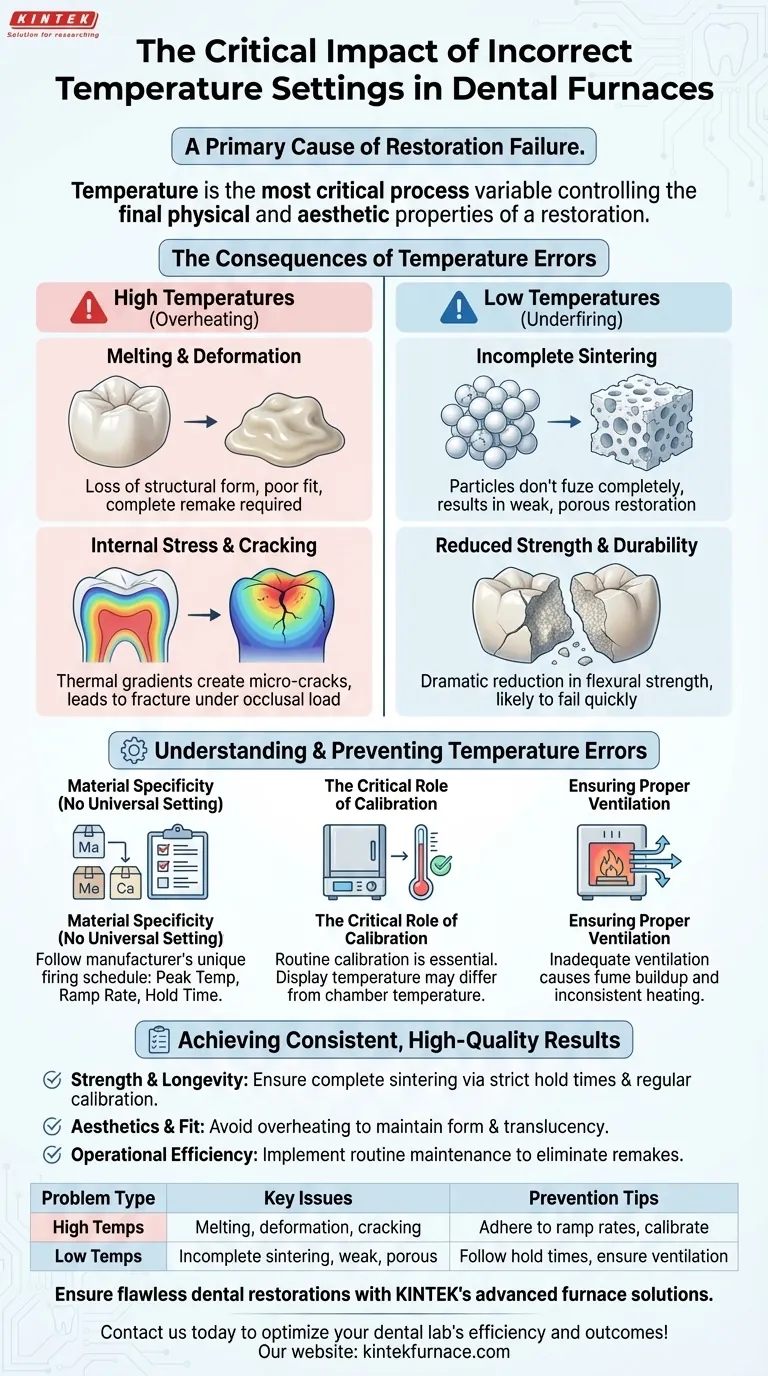

In short, incorrect temperature settings in a dental furnace are a primary cause of restoration failure. When the temperature is too high, materials can melt, deform, or develop internal cracks. Conversely, if the temperature is too low, the material will not sinter completely, resulting in a weak and porous final product that is likely to fail in service.

The temperature setting in a dental furnace is not a mere number; it is the most critical process variable controlling the final physical and aesthetic properties of a restoration. Deviating from the precise thermal protocol transforms a high-strength ceramic into a fragile liability.

The Impact of High Temperatures

Exceeding the specified peak temperature, even for a short duration, can cause irreversible damage to the restoration before it is ever seated. The consequences range from poor fit to catastrophic structural failure.

Melting and Deformation

When a material like zirconia is heated beyond its sintering limit, it begins to lose its structural form. The precisely milled anatomy slumps and distorts.

This deformation makes it impossible to achieve a proper marginal fit, rendering the crown or bridge unusable and requiring a complete remake.

Internal Stress and Cracking

Heating a restoration too quickly or to an excessive temperature creates thermal gradients within the material. The exterior heats faster than the interior, inducing immense internal stress.

This stress is often relieved through the formation of micro-cracks. These cracks may not be visible to the naked eye but represent critical points of failure that can propagate and cause the restoration to fracture under normal occlusal loads.

The Consequences of Low Temperatures

Failing to reach the target temperature is just as detrimental as exceeding it. This error undermines the entire purpose of the sintering process.

Incomplete Sintering

Sintering is the process where individual ceramic particles fuse together, densifying the material and giving it strength. This requires a specific amount of thermal energy.

If the temperature is too low, the particles do not fully fuse. This results in an incomplete sintering cycle, leaving a porous, chalky, and structurally compromised restoration.

Reduced Strength and Durability

The primary consequence of incomplete sintering is a dramatic reduction in flexural strength. The final product will be brittle and unable to withstand the forces of chewing.

A restoration that has been under-fired is a ticking time bomb, almost guaranteed to fracture shortly after being placed in the patient's mouth.

Understanding and Preventing Temperature Errors

Achieving consistent results is not a matter of luck; it is a matter of process control. Understanding the variables and implementing rigorous protocols is the only way to guarantee quality.

The Principle of Material Specificity

There is no universal temperature setting. Each dental material—from different brands of zirconia to various ceramics—has a unique and precise firing schedule provided by the manufacturer.

These schedules specify not just the peak temperature but also the ramp rate (how fast the temperature rises) and the hold time (how long it stays at peak temperature). Following these guidelines exactly is non-negotiable.

The Critical Role of Calibration

A furnace's temperature display is not always accurate. Heating elements age and thermocouples drift over time. A furnace set to 1530°C might only be reaching 1500°C.

Routine calibration is essential to ensure that the temperature displayed is the temperature the chamber is actually achieving. This simple maintenance step prevents a vast majority of temperature-related failures.

Ensuring Proper Ventilation

While not a direct temperature setting, inadequate furnace ventilation can lead to the buildup of fumes and inconsistent heating within the chamber.

This can affect the quality of the sintering process and create hot or cool spots, undermining even the most accurate temperature program.

Achieving Consistent, High-Quality Results

Use these guidelines to diagnose your process and ensure every restoration meets the highest standard of quality and durability.

- If your primary focus is strength and longevity: Ensure complete sintering by strictly adhering to manufacturer-recommended hold times and calibrating your furnace regularly.

- If your primary focus is aesthetics and fit: Avoid overheating at all costs to prevent deformation, maintain prescribed translucency, and guarantee accurate marginal seating.

- If your primary focus is operational efficiency: Implement a routine schedule for furnace calibration and maintenance to eliminate the costly remakes and material waste caused by temperature errors.

Mastering the thermal process is the foundation of creating dental restorations that are not only beautiful but built to last.

Summary Table:

| Problem Type | Key Issues | Prevention Tips |

|---|---|---|

| High Temperatures | Melting, deformation, internal cracking | Adhere to manufacturer ramp rates, calibrate furnace regularly |

| Low Temperatures | Incomplete sintering, reduced strength, porosity | Follow exact hold times, ensure proper ventilation |

Ensure flawless dental restorations with KINTEK's advanced furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability precisely meets your unique experimental needs, preventing temperature errors and enhancing restoration quality. Contact us today to discuss how our solutions can optimize your dental lab's efficiency and outcomes!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations