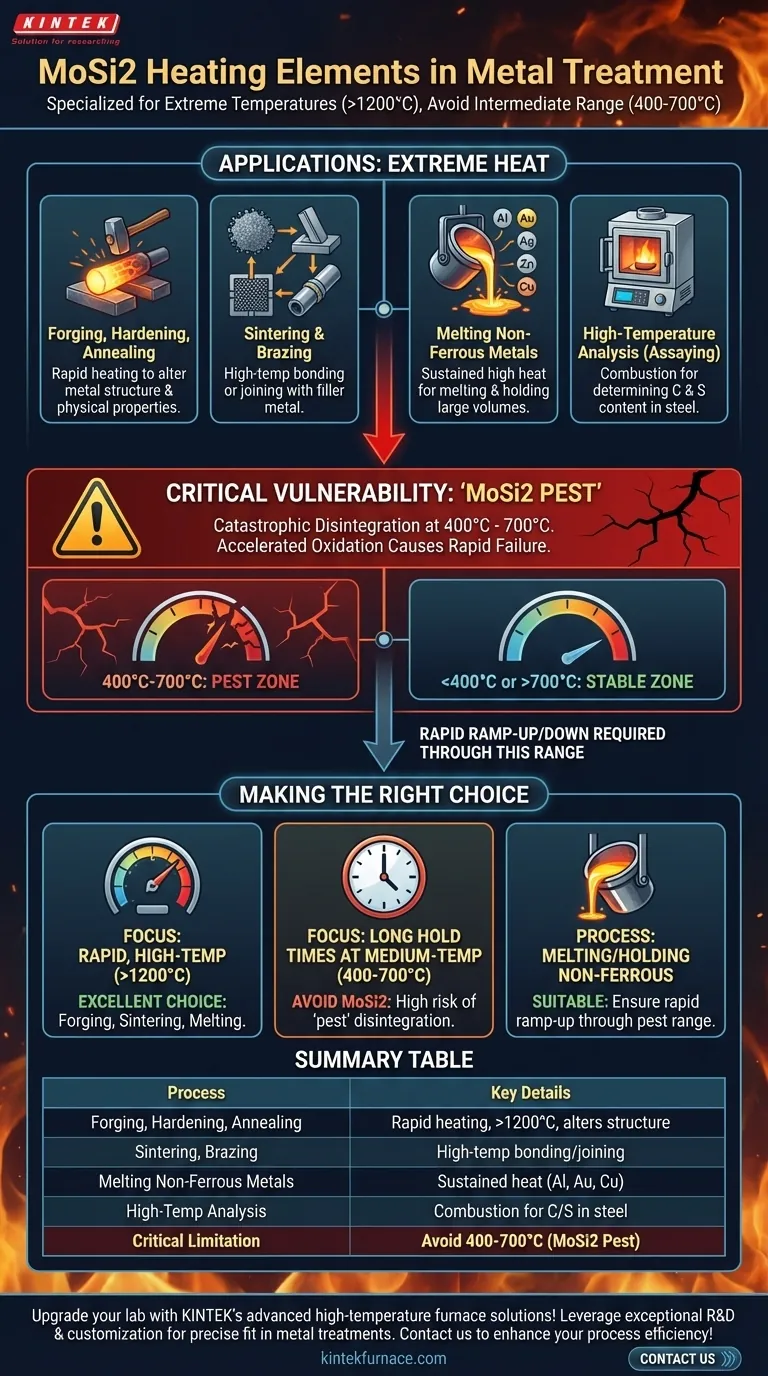

In metal treatment, molybdenum disilicide (MoSi2) heating elements are employed for a range of high-temperature processes. These include forging, sintering, hardening, brazing, annealing, the melting and holding of non-ferrous metals, and specialized analytical techniques like assaying for carbon and sulfur content in steel.

MoSi2 heating elements are not a universal solution; they are specialists. Their value lies in their ability to achieve and sustain the extremely high temperatures (above 1200°C) required for specific metal treatments, but this capability comes with a critical vulnerability to disintegration at lower temperatures.

Why MoSi2 is Chosen for Extreme Heat Applications

The defining characteristic of MoSi2 heating elements is their exceptional performance at very high operating temperatures. This makes them the default choice for industrial furnaces where reaching temperatures beyond the capabilities of standard metallic elements is necessary.

Forging, Hardening, and Annealing

These processes fundamentally alter the crystalline structure of a metal to change its physical properties. This often requires rapid heating to precise, elevated temperatures.

MoSi2 elements provide the intense, responsive heat needed to bring large metal billets up to forging temperature or to execute specific hardening and annealing cycles efficiently.

Sintering and Brazing

Sintering involves heating powdered metal until its particles bond, while brazing joins components using a filler metal. Both processes demand temperatures that approach the melting point of the materials involved.

The high thermal output of MoSi2 elements ensures that the furnace can reach and maintain these critical temperatures uniformly, which is essential for part quality and joint integrity.

Melting and Holding Non-Ferrous Metals

MoSi2 elements are commonly used in furnaces for melting metals like aluminum, gold, silver, zinc, and copper.

Their ability to sustain very high heat is crucial not just for the initial melting but also for holding large volumes of molten metal at a stable temperature for casting or processing.

High-Temperature Analysis (Assaying)

Certain analytical methods, such as determining the carbon and sulfur content in steel, require the sample to be combusted at very high temperatures. MoSi2 elements provide the necessary heat for these specialized laboratory furnaces.

Understanding the Critical Trade-off: "MoSi2 Pest"

While powerful at high temperatures, MoSi2 elements have a significant operational constraint that you must manage. This phenomenon, known as "MoSi2 pest," is their primary weakness.

What Is MoSi2 Pest?

At intermediate temperatures, typically in the range of 400°C to 700°C, the material is susceptible to accelerated oxidation.

This oxidation causes the element to rapidly disintegrate into a fine powder, effectively destroying it. It is not a gradual degradation but a catastrophic failure mode.

The Impact on Furnace Operation

This vulnerability means that furnaces using MoSi2 elements must be programmed to heat up and cool down rapidly through this "pest" temperature range.

Prolonged holding times or slow thermal cycling within this zone are not possible, which can limit the types of complex, multi-stage heat treatment cycles that can be performed. It places a strict constraint on furnace and process design.

Why They Aren't a Universal Solution

This is why MoSi2 elements are not found in lower-temperature equipment like ovens or dryers. For those applications, other resistance materials like nichrome are far more suitable as they are stable across a broader, lower temperature range. MoSi2 is a specialist reserved for the high-end of thermal processing.

Making the Right Choice for Your Process

Your decision to use MoSi2 elements must be driven by your specific temperature requirements and operational constraints.

- If your primary focus is rapid, high-temperature processing (>1200°C): MoSi2 is an excellent choice for its efficiency in forging, sintering, and melting applications.

- If your process involves long hold times at medium temperatures (400-700°C): You must avoid MoSi2 elements, as the risk of "pest" disintegration is extremely high.

- If you are melting or holding non-ferrous metals: MoSi2 provides the necessary sustained heat, but ensure your furnace controls are designed for rapid ramp-up through the pest range.

Ultimately, choosing MoSi2 is a commitment to a high-performance system designed specifically for extreme temperature work.

Summary Table:

| Process | Key Details |

|---|---|

| Forging, Hardening, Annealing | Rapid heating to alter metal structure; requires >1200°C |

| Sintering, Brazing | High-temp bonding of powders or joining with filler metal |

| Melting Non-Ferrous Metals | Sustained heat for metals like aluminum, gold, copper |

| High-Temp Analysis (Assaying) | Combustion at high temps for carbon/sulfur content in steel |

| Critical Limitation (MoSi2 Pest) | Avoid 400-700°C range to prevent disintegration |

Upgrade your lab with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems tailored for diverse laboratories. Our deep customization capability ensures precise fit for unique experimental needs, such as optimizing MoSi2 element use in high-heat metal treatments. Contact us today to enhance your process efficiency and reliability!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the advantages of using high purity green silicon carbide powder in heating elements? Boost Efficiency and Lifespan

- What makes SIC heating elements superior for high-temperature applications? Unlock Efficiency and Durability

- What is the maximum temperature silicon carbide heating elements can withstand? Key Factors for Longevity and Performance

- What are the properties and applications of silicon carbide (SiC)? Unlock High-Temperature Performance

- Why are silicon carbide heating elements essential in high-temperature industries? Unlock Reliable, Extreme Heat Solutions