At a fundamental level, rotary tube furnaces are engineered to continuously process a wide range of granular and powdered materials at high temperatures. These include industrial minerals like alumina and cement clinker, advanced battery components such as graphitized carbon and silicon-based anode materials, and various metal powders and ceramics. The key is that the material must be able to tumble and flow freely as the tube rotates.

The suitability of a material for a rotary tube furnace depends less on its chemical composition and more on its physical behavior. The single most important factor is the material's ability to remain free-flowing and non-sticky at the target processing temperature.

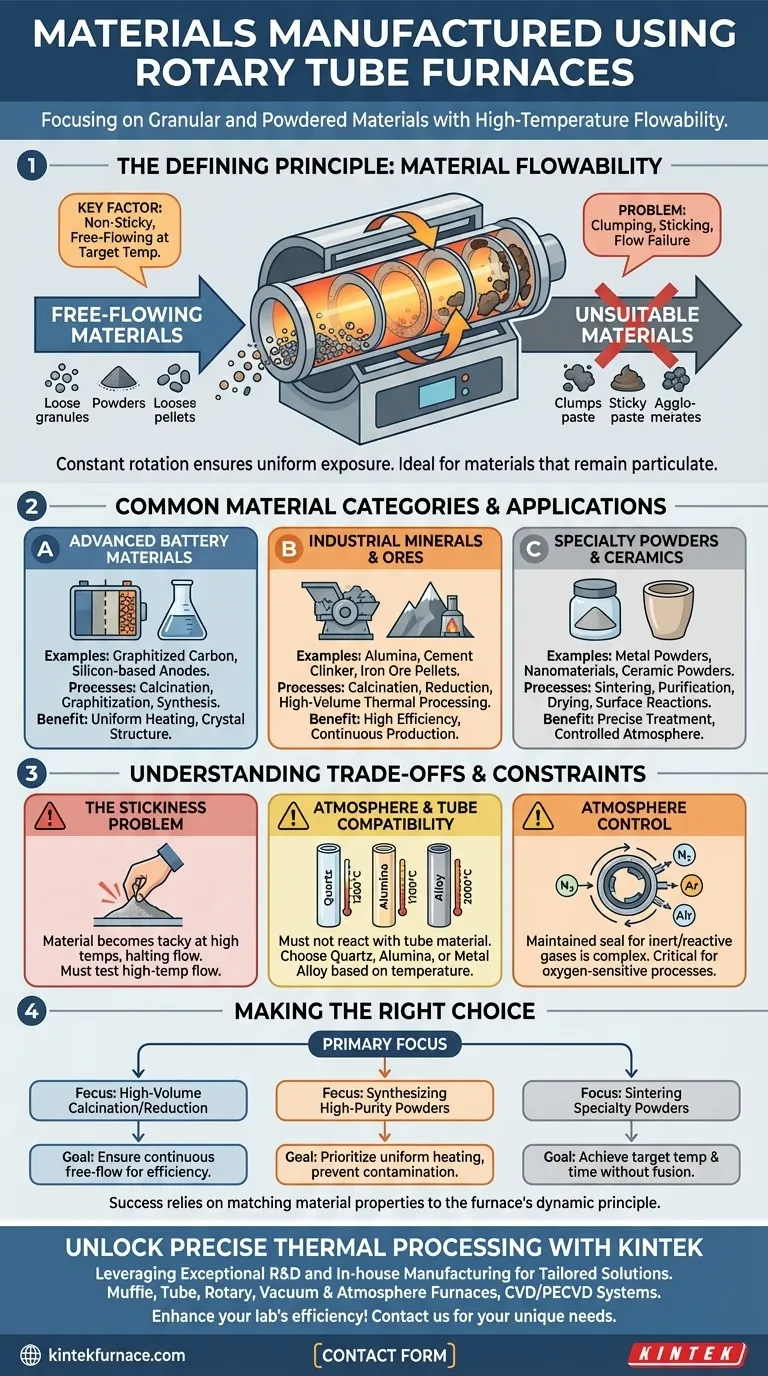

The Defining Principle: Material Flowability

The entire design of a rotary tube furnace is built around the concept of continuous material movement. This mechanical agitation is what makes the technology so effective, but it also defines its primary limitation.

Why Flow is Critical

The constant rotation and tumbling action ensures every particle is exposed to the same temperature and atmospheric conditions. This results in exceptional thermal uniformity and consistent product quality, which is difficult to achieve in a static batch furnace.

Suitable Material Forms

These furnaces excel at processing materials that are inherently granular or particulate. This includes powders, pellets, granules, and small, free-flowing solids. The process ensures each particle undergoes the same thermal treatment.

Unsuitable Material Properties

Materials that agglomerate, soften, or become sticky at high temperatures are not suitable for rotary tube furnaces. Such materials will clump together or adhere to the hot tube wall, halting the flow, causing severe operational problems, and leading to non-uniform processing.

Common Material Categories and Applications

The principle of flowability allows these furnaces to be used across several key industries for specific thermal processes like calcination, sintering, and purification.

Advanced Battery Materials

Rotary furnaces are central to producing next-generation battery components. This includes the synthesis and graphitization of anode materials (like graphitized carbon) and the calcination of cathode materials (positive electrodes). The uniform heating is critical for achieving the desired crystal structure and purity.

Industrial Minerals and Ores

This is a classic application, used for high-volume thermal processing. Common examples include producing cement clinker, reducing iron ore pellets, and the calcination of minerals like alumina and vermiculite. The continuous nature of the process makes it highly efficient for bulk manufacturing.

Specialty Powders and Ceramics

The furnace is ideal for treating metal powders, nanomaterials, and ceramic powders. Processes can include drying, purifying, sintering particles without full consolidation, and performing chemical reactions on a powder's surface.

Understanding the Trade-offs and Constraints

While powerful, a rotary tube furnace is not a universal solution. Understanding its limitations is crucial for successful implementation.

The Stickiness Problem

This is the most common failure mode. A material that seems to flow perfectly at room temperature may become tacky at 800°C. It is essential to test a material's high-temperature flow characteristics before committing to this processing method.

Atmosphere and Process Tube Compatibility

The material being processed must not chemically react with the tube itself. The process tube material—typically quartz, alumina (corundum), or a high-temperature metal alloy—is chosen based on the required temperature and chemical environment.

For example, a standard quartz tube is excellent for many processes but has temperature limitations. High-temperature applications above ~1200°C often require an alumina tube, which is more brittle and susceptible to thermal shock. Extremely high temperatures (approaching 2000°C or 3600°F) may even necessitate a zirconia tube.

Atmosphere Control

While these furnaces can operate with air or an inert atmosphere (like nitrogen or argon), maintaining a perfect seal on a rotating assembly is more complex than on a static tube furnace. This is a critical design consideration for processes that are highly sensitive to oxygen.

Making the Right Choice for Your Goal

To determine if this technology fits your needs, focus on the intended outcome and your material's physical properties.

- If your primary focus is high-volume calcination or reduction of minerals: Your main concern is ensuring the material remains free-flowing throughout the entire temperature profile to enable continuous, efficient production.

- If your primary focus is synthesizing high-purity powders like battery materials: You must prioritize both uniform heating and the chemical compatibility between your material, the process atmosphere, and the tube wall to prevent contamination.

- If your primary focus is sintering or heat-treating specialty powders: Your goal is to achieve the target temperature and residence time uniformly across all particles without allowing them to fuse to each other or to the tube wall.

Ultimately, successful manufacturing in a rotary tube furnace is achieved by matching the material's physical properties to the furnace's dynamic operating principle.

Summary Table:

| Material Category | Common Examples | Key Processes |

|---|---|---|

| Advanced Battery Materials | Graphitized carbon, silicon-based anodes | Calcination, graphitization |

| Industrial Minerals | Alumina, cement clinker, iron ore pellets | Calcination, reduction |

| Specialty Powders and Ceramics | Metal powders, nanomaterials, ceramic powders | Sintering, purification, drying |

Unlock precise thermal processing with KINTEK's advanced rotary tube furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures your unique experimental requirements are met for materials like battery components, minerals, and powders. Contact us today to enhance your lab's efficiency and achieve superior results!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What is the basic construction of a rotary tube furnace? Key Components for Uniform Heating

- How do rotary tube furnaces achieve precise temperature control? Master Uniform Heating for Dynamic Processes

- What factors should be considered when selecting a tube for a rotary tube furnace? Ensure Optimal Performance and Longevity

- What are some industrial applications of rotary tube furnaces? Boost Your Material Processing Efficiency

- What supplementary features can enhance rotary tube furnace performance? Boost Efficiency with Precision Control