The core structure of a box-type annealing atmosphere furnace is most often built from high-temperature alloy steel or stainless steel. These materials are chosen for their ability to withstand intense heat without deforming and to resist corrosion from both the external environment and the controlled internal atmosphere. However, this structural shell is only one component of a sophisticated system designed for thermal efficiency and process integrity.

The selection of materials for a box-type annealing furnace is a strategic balance. It involves choosing materials for the outer structure that provide high-temperature strength, inner linings that ensure thermal efficiency, and chamber surfaces that remain inert to the process atmosphere.

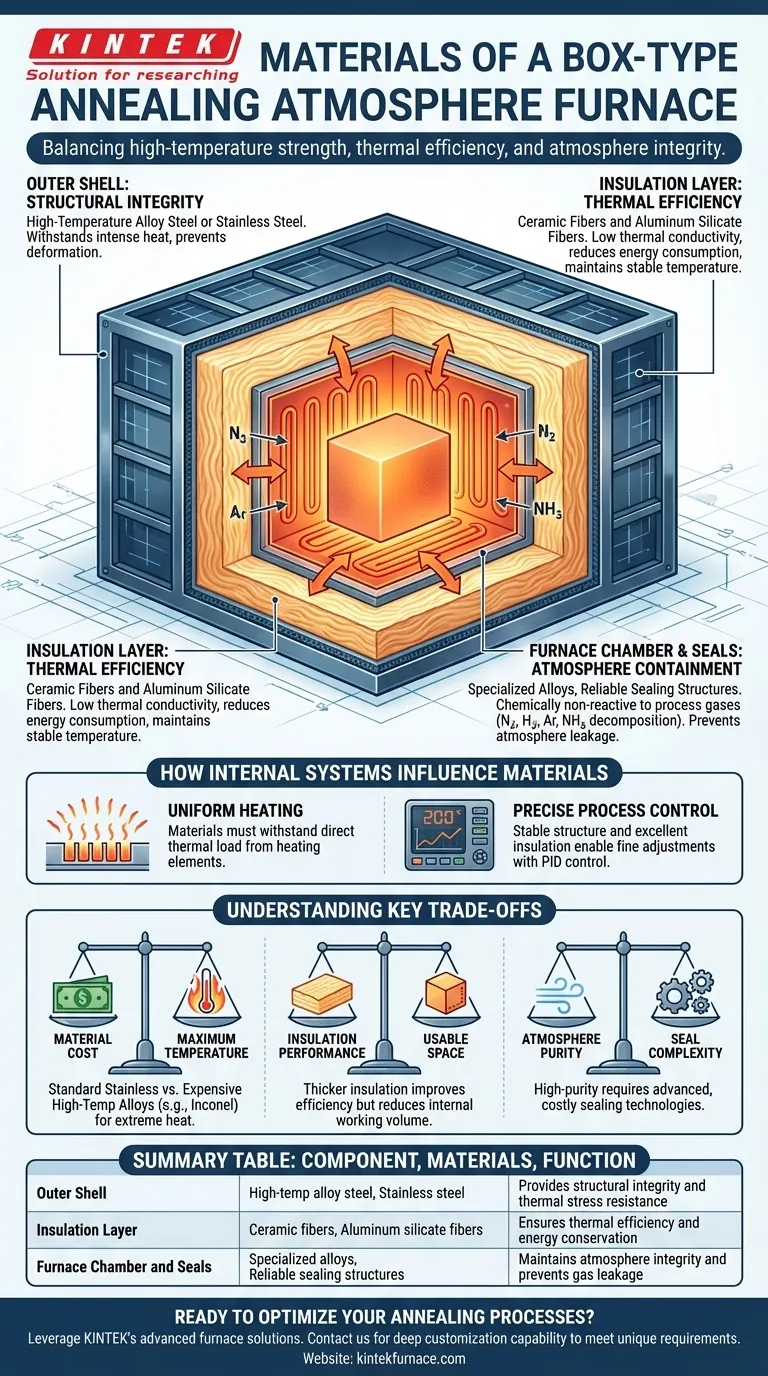

The Core Components of Furnace Construction

A furnace is not a single material but a layered system. Each layer serves a distinct and critical purpose, from providing physical strength to managing extreme heat and containing specialized gases.

The Outer Shell: Structural Integrity

The main body and frame of the furnace are made from high-temperature alloy steel or stainless steel. The primary function of this outer shell is to provide a rigid, stable structure that will not warp or fail under the thermal stress of repeated heating and cooling cycles. This choice ensures long-term mechanical reliability.

The Insulation Layer: Thermal Efficiency

The inner wall of the furnace is lined with high-performance insulation materials. The most common choices are ceramic fibers and aluminum silicate fibers. These materials have extremely low thermal conductivity, meaning they are very effective at preventing heat from escaping. This insulation is critical for reducing energy consumption, maintaining a stable and uniform internal temperature, and keeping the furnace's external surfaces at a safe temperature.

The Furnace Chamber and Seals: Atmosphere Containment

The innermost surfaces and the furnace door must ensure the integrity of the controlled atmosphere. The materials here must not only withstand the heat but also be chemically non-reactive with the process gases, which can include nitrogen, hydrogen, argon, or ammonia decomposition gas. Furthermore, the furnace door uses a reliable sealing structure to prevent atmosphere leakage, which is crucial for achieving the desired metallurgical properties in the workpiece and ensuring operational safety.

How Internal Systems Influence Material Demands

The furnace's structure is designed to support its operational systems, which place their own demands on the materials and overall design.

Uniform Heating

Heating elements are strategically placed around, below, or above the workpiece. They transfer heat via radiation and convection. The furnace's structural and insulation materials must be able to withstand this direct and continuous thermal load while helping to distribute the heat uniformly.

Precise Process Control

A sophisticated temperature control system, typically using thermocouples and a PID controller, manages the heating elements. This system relies on the furnace's physical structure to be stable and predictable. The excellent insulation allows the controller to make fine adjustments to power, ensuring the temperature inside remains precisely at the setpoint without constant, inefficient power spikes.

Understanding the Key Trade-offs

Choosing or designing a furnace involves balancing competing priorities. Understanding these trade-offs is key to selecting the right equipment for a specific task.

Material Cost vs. Maximum Temperature

While standard stainless steel is suitable for many applications, processing materials like titanium alloys at very high temperatures may require more exotic and expensive high-temperature alloys (e.g., Inconel). These provide superior strength and corrosion resistance at extreme temperatures but come at a significantly higher initial cost.

Insulation Performance vs. Usable Space

Increasing the thickness of the ceramic or aluminum silicate fiber insulation will improve energy efficiency and temperature stability. However, this directly reduces the internal working volume of the furnace. A balance must be struck between operational efficiency and the physical size of the parts you need to process.

Atmosphere Purity vs. Seal Complexity

Maintaining a very high-purity atmosphere with minimal contamination requires advanced and often costly sealing technologies and materials. For processes where slight atmospheric variance is acceptable, a simpler and more economical sealing design can be used.

Making the Right Choice for Your Goal

Your specific annealing or brazing application will determine the ideal furnace configuration.

- If your primary focus is general-purpose annealing of standard steels: A furnace with a robust stainless steel structure and quality ceramic fiber insulation is a cost-effective and highly capable choice.

- If you are working with reactive alloys or require very high temperatures: You must invest in a furnace built with specialized high-temperature alloys and a high-performance sealing system to ensure process integrity.

- If energy efficiency and process precision are your top priorities: Look for a furnace with thick, multi-layered insulation (like aluminum silicate fibers) and a modern, well-tuned PID control system to minimize energy waste.

Understanding these material choices empowers you to select a furnace that provides not just heat, but the precise, stable, and controlled environment your process requires.

Summary Table:

| Component | Key Materials | Primary Function |

|---|---|---|

| Outer Shell | High-temperature alloy steel, Stainless steel | Provides structural integrity and resistance to thermal stress |

| Insulation Layer | Ceramic fibers, Aluminum silicate fibers | Ensures thermal efficiency and energy conservation |

| Furnace Chamber and Seals | Specialized alloys, Reliable sealing structures | Maintains atmosphere integrity and prevents gas leakage |

Ready to optimize your annealing processes with a custom furnace solution? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique experimental requirements. Contact us today to discuss how we can enhance your lab's efficiency and performance!

Visual Guide

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What are the two main types of atmosphere furnaces and their characteristics? Choose the Right Furnace for Your Lab

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity

- How does inert atmosphere heat treating benefit aluminum? Prevent Oxide Buildup for Superior Results

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- What industries commonly use inert atmosphere heat treating? Key Applications in Military, Automotive, and More